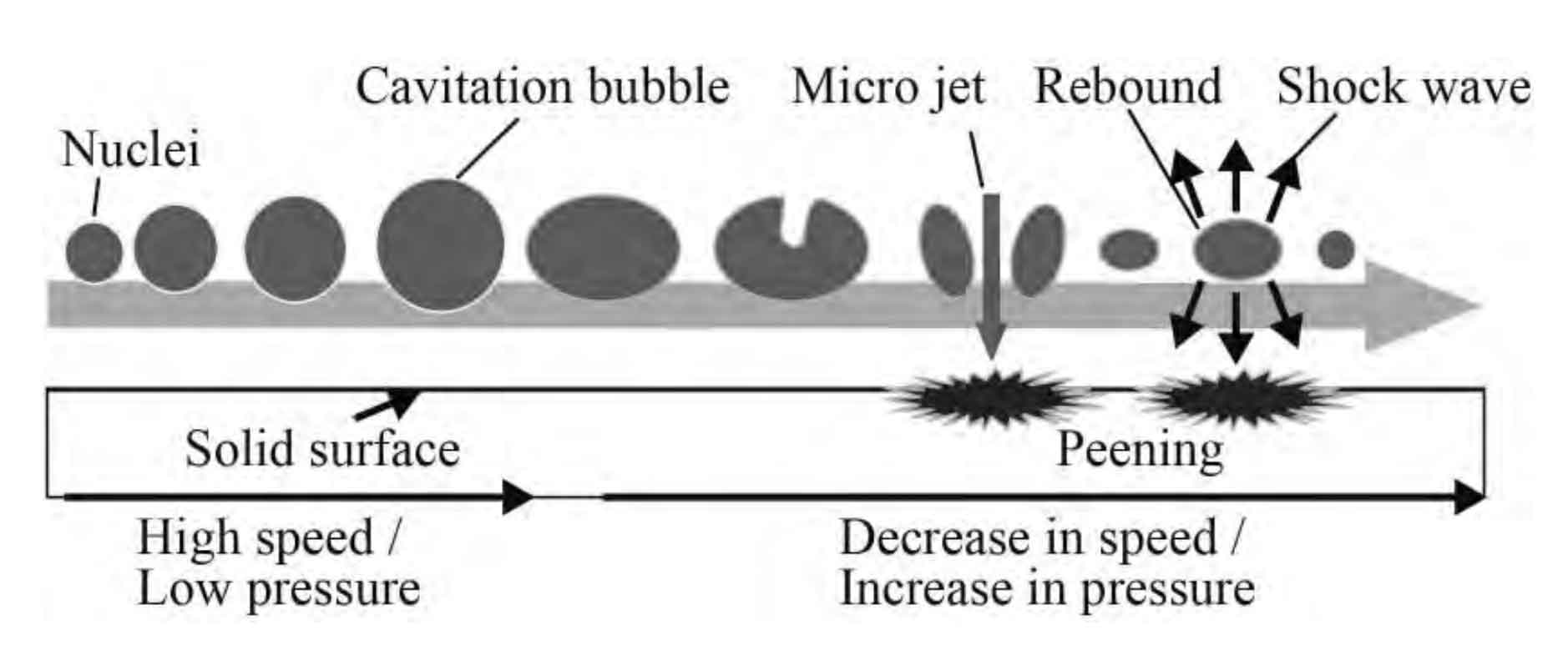

With the development of science and technology, as an important technology to introduce residual compressive stress, change the microstructure of surface materials and enhance fatigue life, new technologies are constantly developed and applied, such as cavitation water peening, laser hole peening, ultrasonic peening and so on. The illustration shows the principle of cavitating water shot peening. This process uses the shock wave pressure and high-speed micro jet generated during the collapse of micro cavitating bubbles to hit the surface of automobile gears, causing the accumulation of high-density dislocations in the surface layer of automobile gears, so as to form a residual compressive stress layer, so as to strengthen the metal surface.

Laser hole peening can peen in a narrow space through the shock wave generated by the collapse of micro cavitation bubbles at the laser focus point. The parameters can be accurately controlled and the residual compressive stress is greater. In ultrasonic peening, the projectile strikes the fixed material surface with ultrasonic frequency from all directions. Due to the large energy introduced into the material, it can be used to realize the nanocrystallization of the material surface and reduce the nitriding temperature.