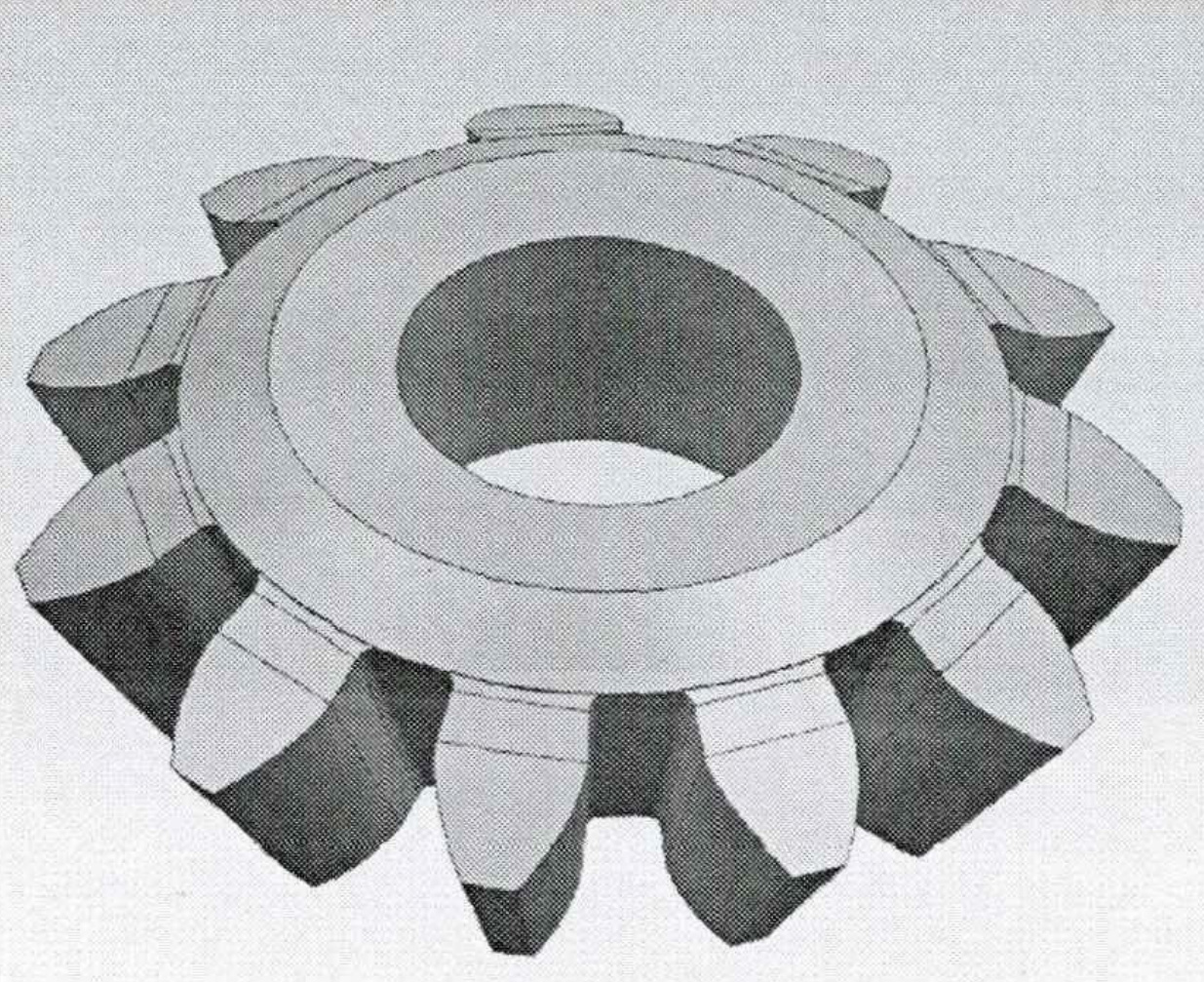

(1) During the precision forging of spur bevel gears, there are many factors that affect the metal flow behavior. In addition to the shape and size of the preform and the preform, there are also the upper die speed, the friction coefficient between the blank and the die, the forging temperature, the shape and size of the flash, etc. it is very necessary to study these factors by using the finite element numerical simulation method to obtain the influence law of these factors on the metal filling performance and forming force.

(2) The involute tooth profile curve equation is combined with the curve command of UG to obtain the tooth profile curve of spur bevel gear. It will be of great practical value to program the involute tooth profile curve equation and the basic tooth profile parameter relationship between the finished gear, forging gear, die cavity and electrode gear, and to develop the tooth profile design module on the UG platform.

(3) A new tooth profile design model for non-linear expansion spur bevel gear hot forgings is proposed. However, due to the insufficient accuracy of DEFORM-3D software, it is impossible to verify the model. It is of great significance to improve DEFORM-3D software or find a finite element software with high accuracy, or verify the model by experimental methods.

(4) DEFORM-3D is a commercial software, which is widely used to simulate the forging process. However, when it is used to simulate the precision forging process, there are some problems: the precision forging process has strict requirements on the volume of the blank, while the volume loss is serious when the mesh is re divided, and the flash is small during the precision forging process. After the forging flash occurs, the mesh is re divided frequently and the distortion is serious. Therefore, it is of great significance to develop the mesh re division module suitable for the precision forging of spur bevel gears on the DEFORM-3D platform for accurately simulating the precision forging process of spur bevel gears.