Introduction

Gear honing is a precision finishing process for hardened gears, where residual stress significantly impacts fatigue strength, dimensional stability, and wear resistance. Internal gear honing involves complex interactions between the honing wheel and workpiece, generating elastic-plastic deformation that induces residual stress. Current research gaps exist in quantifying how honing parameters influence residual stress distributions. This study establishes a finite element model to predict residual stress under varying process conditions, providing theoretical guidance for optimizing gear honing processes.

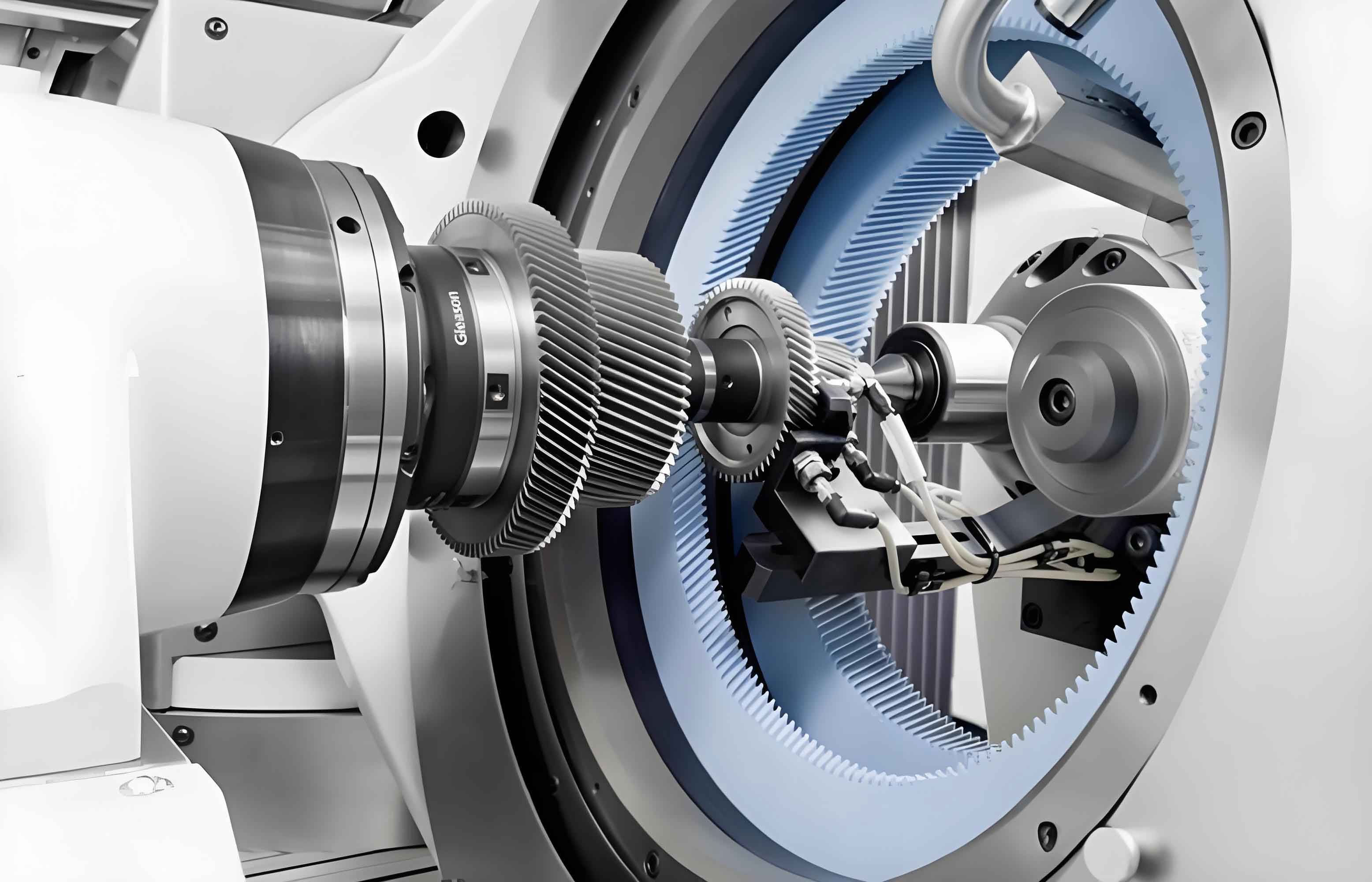

Mathematical Modeling of Internal Honing Wheel

The tooth surface of the internal honing wheel is derived from spatial meshing theory. Coordinate systems are established for the workpiece gear (fixed coordinate system $S(O-x,y,z)$) and honing wheel (fixed coordinate system $S_p(O_p-x_p,y_p,z_p)$). The coordinate transformation matrix $M_{op}$ between $S$ and $S_p$ is:

$$M_{op} = \begin{bmatrix}

1 & 0 & 0 & -a \\

0 & \cos\Sigma & -\sin\Sigma & 0 \\

0 & \sin\Sigma & \cos\Sigma & 0 \\

0 & 0 & 0 & 1

\end{bmatrix}$$

where $\Sigma$ is the shaft angle. The meshing equation satisfies the conjugate contact condition $\vec{v}_{12} \cdot \vec{n} = 0$, where $\vec{v}_{12}$ is relative velocity and $\vec{n}$ is the normal vector. Solving yields the contact line equation:

$$\begin{cases}

x_1 = r_{b1}(\sigma_0 + \theta + \lambda) + r_{b1}\lambda\cos(\sigma_0 + \theta + \lambda) \\

y_1 = r_{b1}\sin(\sigma_0 + \theta + \lambda) – r_{b1}\lambda\cos(\sigma_0 + \theta + \lambda) \\

z_1 = p\theta \\

f_1(\theta, \lambda, \phi_1) = 0

\end{cases}$$

Table 1 shows critical parameters for gear honing simulation:

| Parameter | Workpiece | Honing Wheel |

|---|---|---|

| Teeth (z) | 73 | 123 |

| Helix angle (°) | 33 | 41.722 |

| Module (mm) | 2.25 | 2.25 |

| Pressure angle (°) | 17.5 | 17.5 |

| Face width (mm) | 27 | 30 |

Residual Stress Generation Mechanism

During gear honing, residual stress arises from mechanical deformation and thermal effects. The mechanical contribution dominates due to low honing speeds (≤8 m/s). The honing force components are:

$$\begin{cases}

F_s = F_r / \tan\alpha_n \\

F_a = F_r \cdot \sin\beta / \tan\alpha_n \\

F_n = F_r / \sin\alpha_n

\end{cases}$$

where $F_r$ is radial force, $\alpha_n$ is normal pressure angle, and $\beta$ is helix angle. Key influencing factors include:

| Factor | Impact on Residual Stress |

|---|---|

| Radial force ($F_r$) | Increases compressive stress |

| Relative speed ($v_s$) | Decreases compressive stress |

| Shaft angle ($\Sigma$) | Decreases compressive stress |

| Abrasive grit size | Smaller grits reduce compressive stress |

| Coolant type | Oil-based enhances compressive stress |

Finite Element Dynamic Simulation

A dynamic FE model was developed using SOLID164 elements for deformable bodies and SHELL163 for rigid connections. The symmetric penalty function enforced contact constraints:

$$\begin{cases}

v_{A} \cap v_{B} = \emptyset \\

t_{N}^{A} + t_{N}^{B} = 0 \\

t_{T}^{A} + t_{T}^{B} = 0

\end{cases}$$

Von Mises stress during meshing was calculated as:

$$\sigma = \sqrt{\sigma_{11}^2 + \sigma_{22}^2 + \sigma_{33}^2 – \sigma_{11}\sigma_{22} – \sigma_{22}\sigma_{33} – \sigma_{33}\sigma_{11} + 3(\sigma_{12}^2 + \sigma_{23}^2 + \sigma_{31}^2)}$$

Residual stress variation under different gear honing parameters shows:

| Parameter | Unit 56621 | Unit 56326 | Unit 56606 |

|---|---|---|---|

| $v_s$ = 3 m/s | -550 | -605 | -1200 |

| $v_s$ = 6 m/s | -320 | -365 | -780 |

| $F_r$ = 150N | -550 | -605 | -1200 |

| $F_r$ = 1000N | -1250 | -1350 | -1620 |

| $\Sigma$ = 8° | -550 | -605 | -1200 |

| $\Sigma$ = 16° | -180 | -210 | -520 |

Microscopic Abrasive Grain Analysis

At the microscale, polyhedral abrasive grains were modeled with normal height distribution ($\mu$=5μm, $\sigma$=14μm). The grit velocity $v_g$ versus residual stress follows:

$$\sigma_R = -205 \ln(v_g) + 352 \quad (R^2 = 0.96)$$

Multigrain simulation confirmed that increasing grit velocity reduces compressive residual stress during gear honing, consistent with macroscopic results.

Conclusion

Residual stress in internal gear honing is primarily mechanically induced and shows strong dependence on process parameters. Compressive residual stress increases with radial force but decreases with honing speed and shaft angle. The FE model predicts residual stress with <13.6% error versus experimental measurements. Optimizing gear honing parameters can enhance surface integrity and fatigue performance of precision gears.