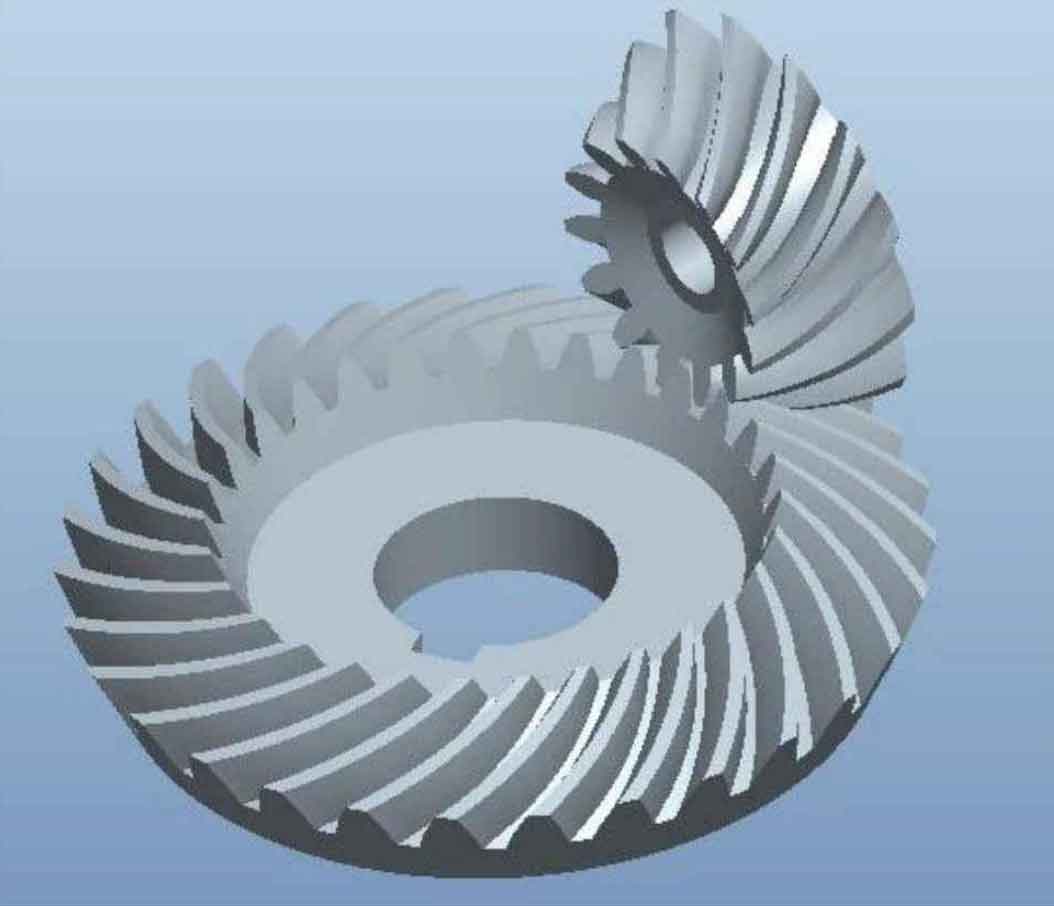

Drive axle vibration often produces annoying sound, which affects the transmission efficiency of the drive axle and reduces the fatigue life of various components of the drive axle, especially for moving parts, such as gears, bearings, etc. The vibration of drive axle is essentially the dynamic response of hypoid gear transmission error and meshing stiffness to time-varying meshing characteristic excitation. Therefore, in order to design a more quiet, efficient and reliable drive axle, it is necessary to comprehensively study the time-varying meshing characteristics of hypoid gear pairs and the dynamic behavior of the drive axle system.

A large number of experimental studies show that the vibration and noise of the drive axle are affected by the dynamic characteristics of the hypoid gear system. In 1975, Abe et al. Showed through tests that adding an inertia plate to the flange of the rear drive axle or reducing the size and stiffness of the gear shaft can reduce the gear noise of the drive axle. In 1991, hirasaka et al. Conducted an experimental study on the vibration sensitivity of the transmission system caused by the transmission error of the drive axle hypoid gear. The results show that the torsional vibration of the transmission system significantly affects the dynamic meshing force of gears. In 2011, Brecher et al. Proposed a new method to measure the dynamic transmission error level of the transmission system, taking into account the influence of the transmission system components, and established the correlation between the dynamic transmission error and the transmission noise. In 2011, Yoon et al. Established a three-axis transmission error measurement process to define the gear whine caused by the installation deviation of the rear axle of the car.

It can be seen from the public information that there are usually two methods to control the vibration and noise of the drive axle. The first is to consider the quasi double curved surface transmission error as the main excitation source of vibration and noise of the drive axle system, and reduce the system excitation by optimizing the shape of the gear transmission error and reducing its amplitude [9]. The other is to adjust the vibration response sensitivity of transmission error within the frequency range we are concerned about, and optimize the dynamics system of hypoid gear pair. Therefore, in order to study the noise generation mechanism of the drive axle, the dynamic characteristics of the drive axle are analyzed from two aspects: the time-varying meshing characteristics of the drive axle gears and the prediction of the vibration and noise of the drive axle system.