First of all, the professional D80 gear measuring and Testing Center (Figure 1) is used to measure the accuracy of the original test gear (Figure 2) after manufacturing. The measuring accuracy of D80 gear measuring and testing center is micron level, and the gear accuracy is based on the relevant domestic standard GB / t10095.1-2008 cylindrical gear accuracy system Part 1 The measurement is divided into two parts: definition and allowable value of tooth surface deviation on the same side of tooth and GB / T 10095.2-2008 cylindrical gear accuracy system Part 2: definition and allowable value of radial comprehensive deviation and radial runout. The relevant measurement results of original gear accuracy of test gear are as follows.

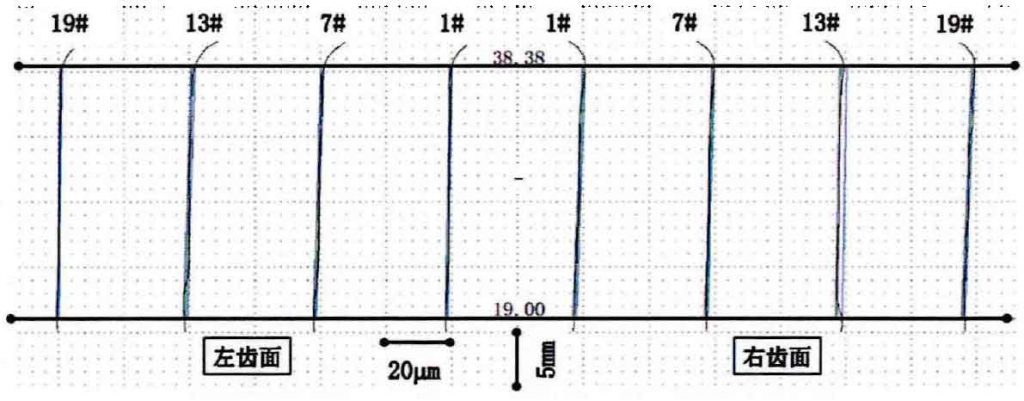

Figure 3 draws and records the original profile deviation diagram and relevant statistical measurement table of gear No. aa-1 measured by D80 gear measuring center. In the chart, 1, 7, 13 and 19 represent the tooth number of aa-1 gear in turn. In Figure 3, the left side is the left tooth surface of the marked tooth, and the right side is the right tooth surface of the marked tooth. From the tooth profile deviation curve, the deviation value is very small. The original profile measurement data show that the average value of the total deviation of the left tooth profile of the marked tooth is 2.6 μ m, and the maximum value is marked 13, which is 3.3 μ m; the average value of the shape deviation of the left tooth profile is 0.9 μ m; the average value of the inclination deviation of the left tooth profile is 2.0 μ m; the average value of the crown of the left tooth profile is 0.3 μ M. At the same time, the average values of the profile deviation indexes corresponding to the right tooth face are 3.0 μ m, 1.3 μ m, 2.6 μ m and 0.4 μ m respectively. Considering the profile deviation index data of left and right tooth surfaces, the maximum values of the corresponding profile deviation indexes (total deviation, shape deviation, inclination deviation and crown) are 3.6 μ m, 2.2 μ m, 3.3 μ m and 0.7 μ m respectively. By referring to GB / t10095.1-2008 and comparing the measured data with the grade 5 precision index data, it can be concluded that the average or maximum value of the tooth profile deviation of the test gear is less than the grade 5 precision index.

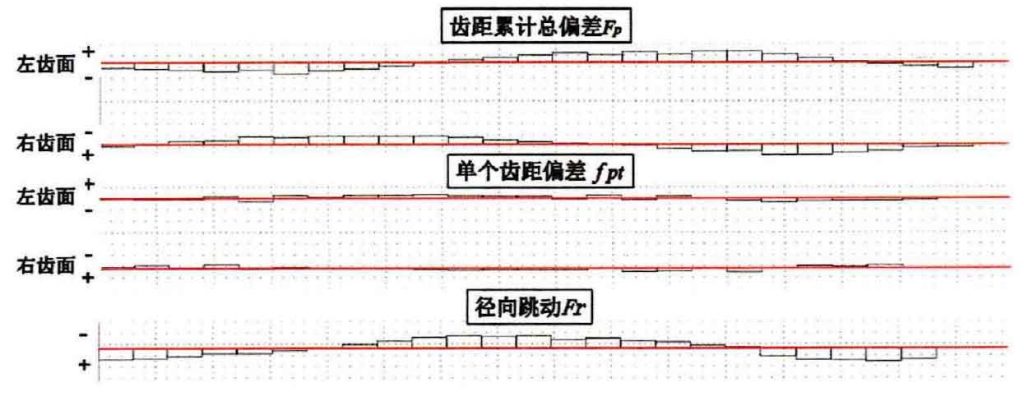

In the same way, figure 4 draws and records the original pitch deviation diagram of aa-1 gear and relevant statistical measurement table. Figure 7-6 shows that the cumulative total pitch deviation, single pitch deviation and radial runout deviation and other indicators show positive and negative alternating changes along the left and right tooth surfaces. In order to facilitate data comparison and analysis, the maximum absolute value of each indicator is selected for numerical comparison. The maximum values of relative pitch deviation indexes (cumulative total deviation, single pitch deviation, adjacent pitch deviation and radial runout) are 8.2 μ m, 1.5 μ m, 2.4 μ m and 9.2 μ m respectively. By comparing with the corresponding 5-level precision reference value, the index value of pitch deviation of the test gear is less than the 5-level precision reference value. Compared with the measured data of tooth profile deviation and pitch deviation of the test gear, the results show that the manufactured test gear has higher tooth surface accuracy, which meets the design requirements and test accuracy requirements of the test gear.