Abstract:

Gear milling machines play a pivotal role in the machinery industry of our country. In recent years, with the development of the economy and society, gear milling machines have also undergone substantial development, and the application of numerical control (NC) bevel gear milling machines has become increasingly prevalent. Currently, NC bevel gear milling machines are widely promoted and applied in various fields such as vehicles, airplanes, and various machine tools due to their characteristics of smooth transmission and strong workpiece carrying capacity. In the application of NC bevel gear milling machines, the adoption of roll-cutting for correction can not only enhance the service life of gears but also reduce the noise generated between gears, making it significant. This paper introduces NC bevel gear milling machines and analyzes the related issues of roll-cutting correction based on this, hoping to contribute to the development of milling machines.

Keywords: NC gear milling; roll-cutting correction

1. Introduction

As an essential mechanical component, bevel gears play a significant role in the machinery industry of our country. With the advancement of economic society and science and technology, NC bevel gear milling machines have undergone rapid development and their applications have become more extensive. Advanced NC bevel gear milling machines generally utilize tool-tilt mechanisms, which are also more widely designed and applied. As a result, traditional NC bevel gear milling machines are gradually being phased out, which increases production costs for enterprises and results in resource waste. In response to this issue, roll-cutting methods can be employed for correction, thereby improving the utilization efficiency of these traditional NC bevel gear milling machines and reducing enterprise operating costs. The necessity and specific applications of roll-cutting correction for NC bevel gear milling machines are analyzed in detail below.

2. Overview of NC Bevel Gear Milling Machines

NC bevel gear milling machines are devices that mainly use NC technology for precision machining of gears. This equipment can be used for mass production of gears for mining machinery, ships, large trucks, and various engineering machinery, making significant contributions to the development of the machinery industry. The structure and working principle of NC milling machines involve multiple technologies such as computer technology, automatic control technology, and mechanical manufacturing technology.

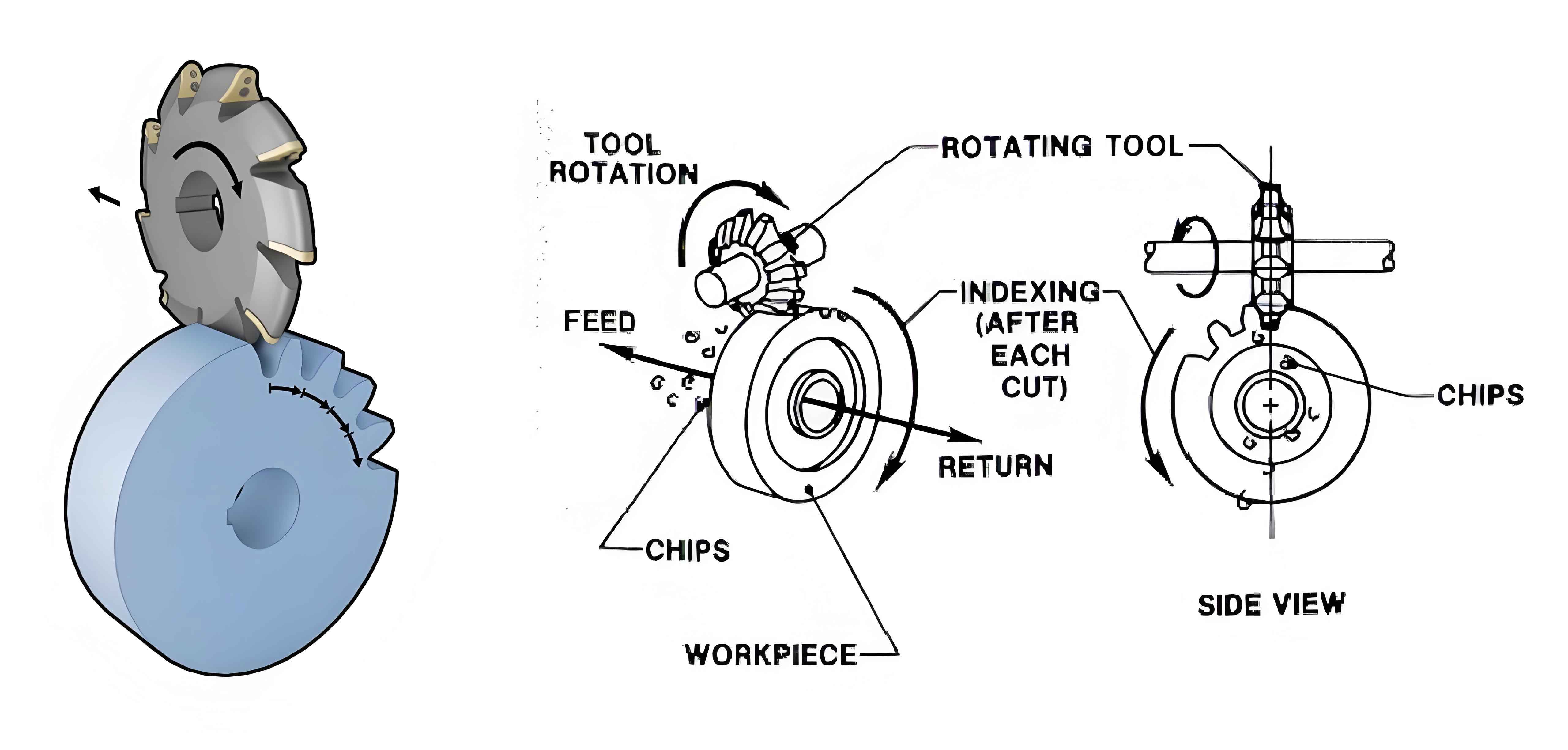

2.1 Structure and Working Principle

In terms of the working principle, traditional mechanical milling machines control the movement of the rocking table through a relatively complex transmission system, while the working principle of NC milling machines is similar but also differs. It controls the movement of the axis through NC technology. Compared with traditional mechanical milling machines, NC milling machines not only simplify their structure, reduce error accumulation, but also improve accuracy and ensure smoother operation. NC milling machines can be classified into two types: with a tool-tilt mechanism and without a tool-tilt mechanism. Due to the complexity of the structure of NC bevel gear milling machines with a tool-tilt mechanism, the application of roll-cutting correction methods is analyzed below using general NC bevel gear milling machines without a tool-tilt mechanism as an example.

3. Necessity of Roll-Cutting Correction for NC Bevel Gear Milling Machines

NC bevel gear milling machines are devices that mainly use NC technology for precision machining of gears. This equipment can be used for mass production of gears for mine machinery, ships, large trucks, and various engineering machinery, making significant contributions to the development of the machinery industry. In recent years, driven by economic and social development, NC bevel gear milling machines have undergone rapid development, making their applications even more extensive. Currently, advanced NC bevel gear milling machines generally utilize tool-tilt mechanisms, which are also more widely designed and applied. As a result, traditional NC bevel gear milling machines are gradually being phased out, which increases production costs for enterprises and results in resource waste. In response to this issue, roll-cutting methods can be employed for correction to improve the utilization efficiency of these traditional NC bevel gear milling machines and reduce enterprise operating costs. Therefore, roll-cutting correction for NC bevel gear milling machines is very necessary.

4. Roll-Cutting Correction for NC Bevel Gear Milling Machines

4.1 Working Principle of Roll-Cutting Correction

When performing roll-cutting correction on NC bevel gear milling machines, the general working principle is to correct the contact area of the gear by continuously changing the rotation speed of the rocking table during the gear machining process. Specifically, when using general roll-cutting methods for processing, the installation base cone angle of the machine tool is mainly adjusted according to the adjustment card in the machine tool. During the processing, the angle of rotation of the rocking table is the swing angle of the rocking table, and the workpiece will rotate at a certain angle according to the rolling ratio. Throughout the process, both the rocking table and the workpiece rotate at a constant speed according to a fixed rolling ratio. However, when using the roll-cutting correction method for processing, when the base cone angle of the machine tool is adjusted again using the machine tool adjustment card, the workpiece still rotates at a constant speed, but the starting and ending angles of the rocking table will change, and it does not move at a constant speed.

4.2 Application in Gear Milling Processing Examples

In NC bevel gear milling machines, assume that the rocking table rotates clockwise to cut the lower tooth surface of the tooth groove. If the swing angle of the rocking table is set to R365, the angle of the rocking table is R366, and R365 is evenly distributed, while the roll-cutting correction coefficient is R369, the swing angle equivalent of the workpiece is R371, and the general roll-cutting method has a swing angle equivalent of R372, with a total number of cutting steps of R377. Accordingly, relevant calculation formulas can be used to obtain the starting and ending angles of the workpiece processing. Through calculations and experiments, it is found that the contact area of the gear has changed.

Table 1: Comparison of Contact Areas Before and After Roll-Cutting Correction

| Processing Method | Contact Area Characteristics |

|---|---|

| General Roll-Cutting | The contact area is relatively uniform, but may have areas unfavorable for gear engagement |

| Roll-Cutting Correction | The contact area changes significantly, with the tooth top and tooth root moving towards the middle of the tooth |

Compared with general roll-cutting processing methods, roll-cutting correction processing results in significant changes in the contact area of the gear, with the tooth top and tooth root moving towards the middle of the tooth. This greatly reduces the noise generated during gear meshing and increases the service life of the gear, promoting the development of machinery and equipment. Additionally, a fixed adjustment method was used to verify the contact area. In the fixed adjustment method, the large wheel uses a forming method, and the small wheel uses a roll-cutting method. Through this experiment, it was also concluded that the roll-cutting correction method significantly changes the contact area of the gear, for instance, by eliminating areas unfavorable for gear engagement along the diagonal line, making machine tool adjustment more convenient and faster.

5. Advantages of Roll-Cutting Correction

Regardless of the verification method used, the conclusion is consistent: the use of the roll-cutting correction method for NC bevel gear milling machines improves the condition of the gear contact area, reduces noise during gear use, and enables better application of general NC bevel gear milling machines. This indicates that the use of the roll-cutting correction method allows some general NC milling machines to achieve the same effect as high-end NC milling machines.

6. Conclusion

In summary, NC bevel gear milling machines occupy a pivotal position in machinery industrial equipment in our country and are closely related to the development level of our machinery industry. Therefore, in the new era of social development, we must attach great importance to NC bevel gear milling machines. In the application of NC bevel gear milling machines, we adopt the roll-cutting correction method for correction, which improves the condition of the gear contact area, reduces noise during gear use, and enables better application of general NC bevel gear milling machines. This demonstrates that the use of the roll-cutting correction method allows some general NC milling machines to achieve the same effect as high-end NC milling machines. In the future, we should strengthen research and application of roll-cutting correction methods to enable NC bevel gear milling machines to better play their role and make greater contributions to the development of our country’s machinery manufacturing industry, continuously driving the advancement of our country’s machinery industry.