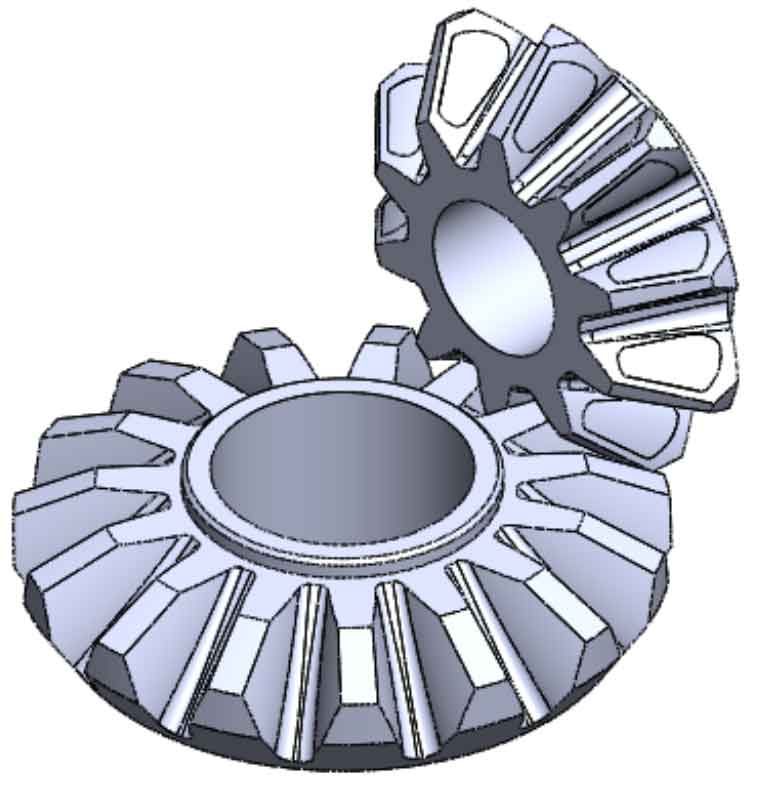

Straight bevel gear is widely used in mechanical transmission, especially in automobile transmission mechanism. The traditional straight bevel gear processing adopts the metal cutting method, and each tooth is gradually processed by a special gear cutting machine tool. This process method has many disadvantages.

In recent years, China has begun to focus on developing more promising plastic forming process to replace the original processing methods, especially the precision forming process aiming at net forming or near net forming is becoming the development direction of gear processing technology. The more advanced and widely used gear processing technology at home and abroad is thermal precision die forging, which can improve the strength and bending fatigue performance of gears, reduce the amount of heat treatment deformation, improve product accuracy, save materials, reduce man hours and reduce production costs. However, it still has the above disadvantages of hot forging; There are many processes and large energy consumption, so it needs to be strictly controlled

As for the heat temperature, the oxide scale on the forging shall not be too much, which needs to be removed in time. It is best to use non oxidation heating.

Some achievements have also been made in the swing rolling of straight bevel gear. The rigid plastic finite element simulation of the swing rolling deformation process of straight bevel gear is carried out by using the finite element commercial software DEFORM-3D, and the metal flow, equivalent force, rolling pressure and time curves of the swing rolling deformation of straight bevel gear, as well as the influence of process parameters on the failure of the swing rolling die of straight bevel gear are obtained, Finite element analysis of warpage in rotary forging of thin disk parts.