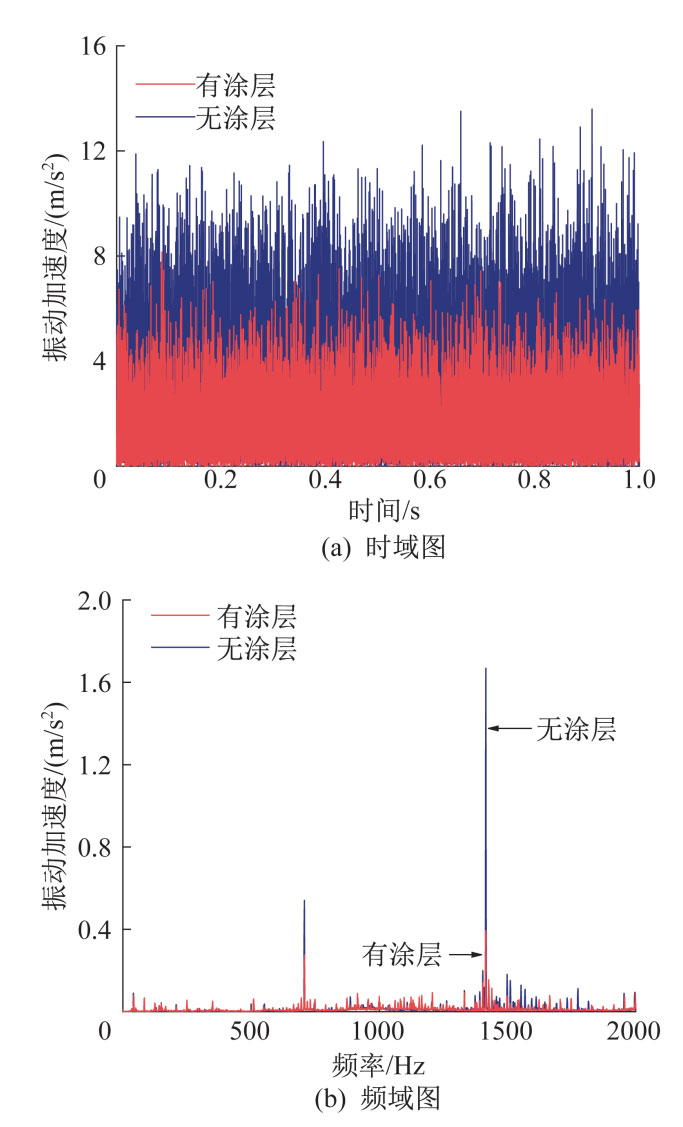

Conduct a running in experiment on a helical gear pair with/without coating at 2500 r/min and 230 N · m, and obtain the state of the helical gear tooth surface after running in, as shown in Figure 1. As shown in the figure, the contact area of the coated helical gear has been well extended under the action of inter tooth load, exhibiting good running in performance.

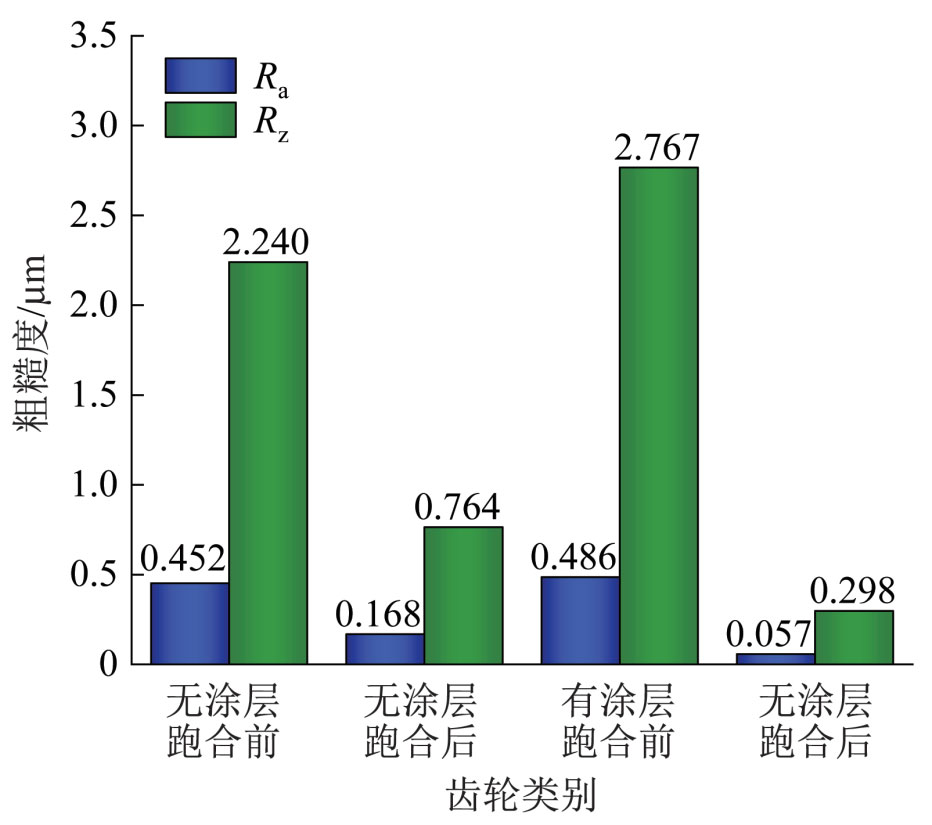

The surface roughness of the helical gear before and after running in was measured using a surface roughness measuring instrument, and the results are shown in Figure 2. As shown in the figure, the Ra value of coated helical gears before running in is 7.5% higher than that of uncoated helical gears, and the Rz value is 23.5% higher; The Ra value of uncoated helical gears after running in is 0.168 μ m. Reduced by 63%, Rz value is 0.764 μ m. Reduced by 66%; After running in, the Ra and Rz values of the coated helical gears are 0.057, respectively μ M and 0.298 μ m. Reduced by 88.3% and 89.2% respectively compared to uncoated helical gears. The results show that the surface roughness of helical gears increases after being treated with manganese phosphate conversion coating; After running in, the surface roughness of both coated and uncoated helical gears decreased, and the tooth surface became smoother. Among them, the surface roughness of coated helical gears decreased significantly compared to uncoated helical gears after running in, indicating that coating can improve the surface morphology of helical gears and the meshing state of helical gears under the action of inter tooth load.

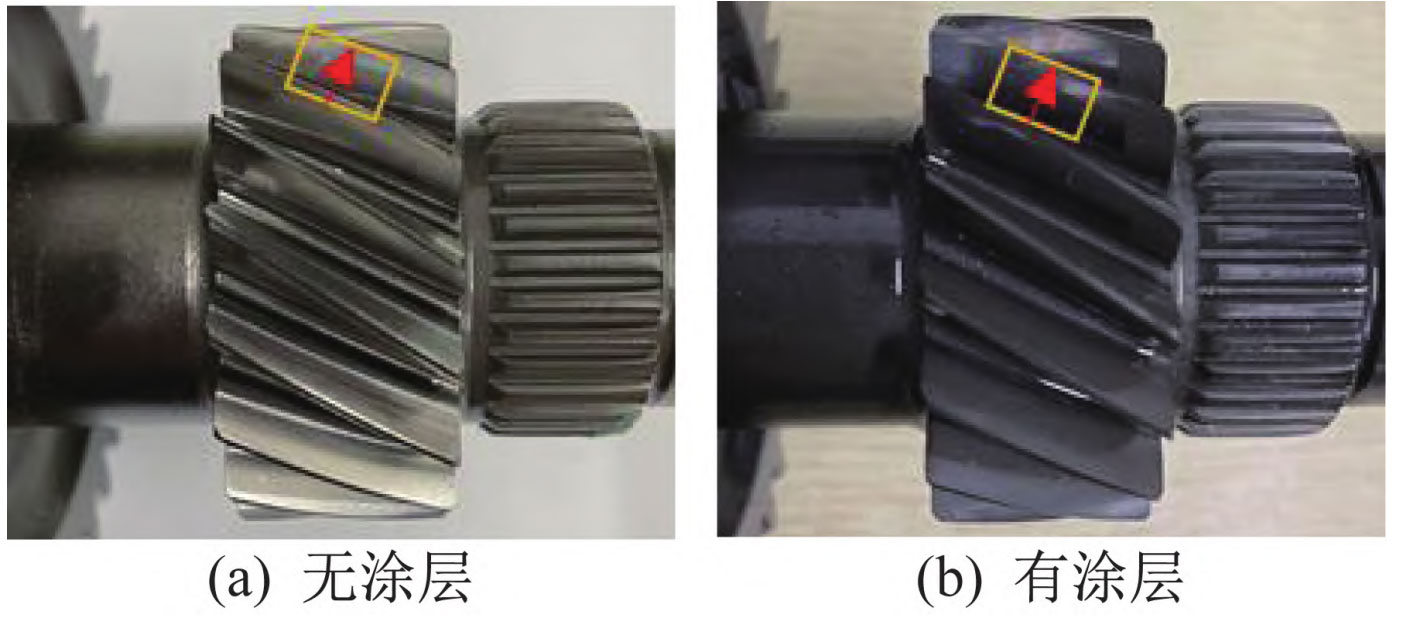

At the same time, the vibration acceleration signal at the input end of the small helical gear end cover is collected in the running in experiment. Set the sampling frequency to 8000 Hz and perform time and frequency domain analysis on the collected data, as shown in Figure 3. From Figure 3 (a), it can be seen that the vibration acceleration amplitude of coated helical gears is small and the variation is also small; Figure 3 (b) shows the frequency domain signal obtained from time-domain data after fast Fourier transform. From the spectrum, it can be seen that the vibration acceleration amplitude of coated helical gears is significantly lower. The vibration acceleration amplitude of coated helical gears is 0.39 m/s2, and that of uncoated helical gears is 1.67 m/s2, a decrease of 76.65%. Experiments have shown that the running in performance of coated gears has been significantly improved, and the operation of helical gear pairs is smoother. The manganese phosphate conversion coating is a soft coating that can effectively reduce the meshing impact of the tooth surface during the initial running in stage of the helical gear, and improve the transmission performance of the helical gear system.