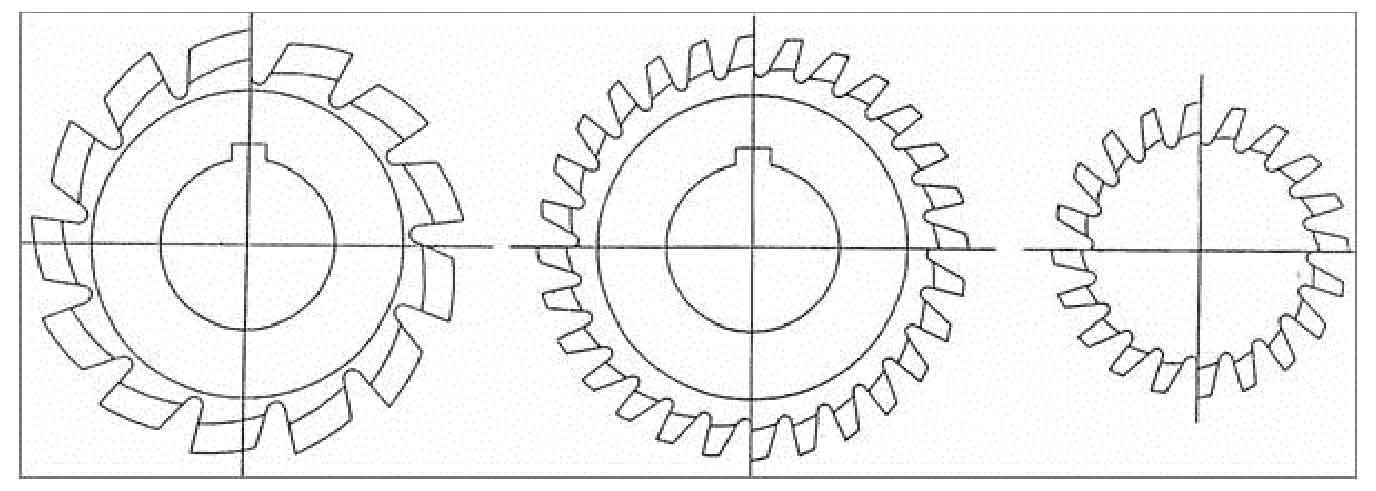

Gear hobbing multi groove hob is shown in the figure. When using gear hobbing multi groove hob, the following conditions shall be met:

(1) Ensure that the blade back of the cutter tooth has sufficient service length (grinding times) and sufficient stiffness;

(2) There is enough chip holding space (included angle 25 ° – 30 °) to prevent chip extrusion, especially the gear hobbing hob used for strong cutting and dry cutting has a large enough arc radius at the groove bottom to prevent chip extrusion;

(3) The selection of the minimum hob diameter of gear hobbing should consider the factors such as the inner hole of the tool, the number of grooves and the effective edge back length; For hobs with the same size and diameter, increasing the number of grooves will shorten the effective tooth length of gear hobbing hob teeth and reduce the number of grinding;

(5) Small diameter gear hobbing hob should keep the same grinding times of large diameter gear hobbing hob, only reduce the number of gear hobbing hob slots;

(6) Without precision and high efficiency gear hobbing machine, the multi slot hob will not play its role well, can not get the due tooth profile accuracy and machining efficiency, and sacrifice the service life of the tool.