The cutting parameters of gear hob include cutting depth, cutting speed and axial feed. The determination of these parameters should be based on the modulus, material and accuracy of the processed gear, the material and structure of gear hob, the rigidity and power of machine tool and other factors. The cutting depth can be one, two or more times according to the gear module.

When the modulus of the workpiece is large, the number of gear hobs is large, and the hardness of the workpiece is high, it is recommended to lower the cutting speed and adopt two tool fine cutting; Or for the fine cutting of hardened teeth, the cutting speed should be improved.

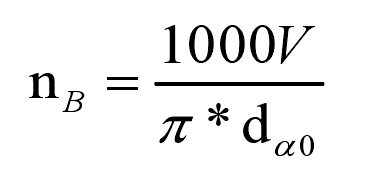

After the cutting speed is determined, calculate the gear hob speed according to the following formula:

Da0 – outer diameter of gear hob

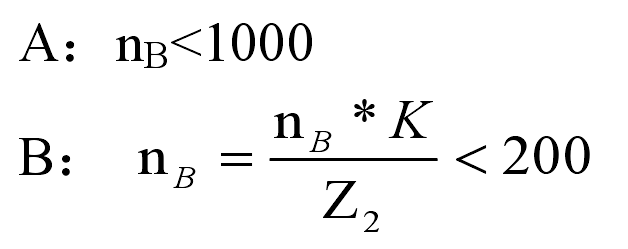

After determining the speed, ensure that Nb meets the following two conditions at the same time:

NC – table speed

K – number of gear hob heads

Z2 – number of workpiece teeth

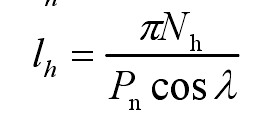

If the selected cutting speed cannot be satisfied at the same time. The axial feed rate is the displacement of z-axis movement per minute (mm / min), which is calculated by the following formula:

FZ – axial feed rate

The factors affecting the selection of FZ are: machine tool processing capacity; Number of gear hobs, number of gear hobs, material of gear hobs and service life of gear hobs; Workpiece hardness, workpiece mandrel rigidity, workpiece clamping rigidity; Workpiece machining accuracy, etc.

In fact, a large factor in the selection of FZ is selected by the operator or technician based on experience. Generally, the rough machining FZ is larger, and the finish machining should ensure the accuracy of tooth profile and tooth direction and reduce the roughness of tooth surface. Generally, the FZ is smaller.

Here are some factors to consider when selecting FZ based on experience.

The influence on FZ when cutting with multi head hob.

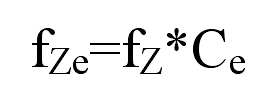

The axial feed FZE when cutting with multi head hob shall adopt the coefficient CE on the axial feed FZ when cutting with single head hob and the axial feed FZ when cutting with single head hob. Namely:

FZ – axial feed during cutting with single head hob

CE – axial feed coefficient during multi head hob cutting, usually 0.3 ~ 0.99 according to experience. The larger the number of gear hobs, the smaller the CE value.