According to the analysis of dynamic and static contact stress of different helical gears, the following conclusions can be obtained:

① In the static contact stress analysis of helical gears, under the condition of the same number of teeth, the calculation error of the local tooth model of the belt rim is small; Under the condition of different number of teeth, the calculation error of five tooth local tooth model with rim and without rim is smaller than that of the corresponding three tooth model; The contact mark of the three tooth model without rim is not clear, and the contact stress distribution of helical gear is uneven. The contact mark of other models is similar to that of the full tooth model, and the contact stress distribution is uniform.

② In the dynamic contact stress analysis of helical gears, the number of teeth in the local tooth model is small, and the variation regularity of the maximum equivalent stress is not obvious, especially in the less tooth model without rim; For the local tooth model with the same number of teeth, the calculation error of the local tooth model with rim is smaller than that without rim; For the local tooth model with different number of teeth, the calculation error of three tooth belt flange model and five tooth belt flange model is small.

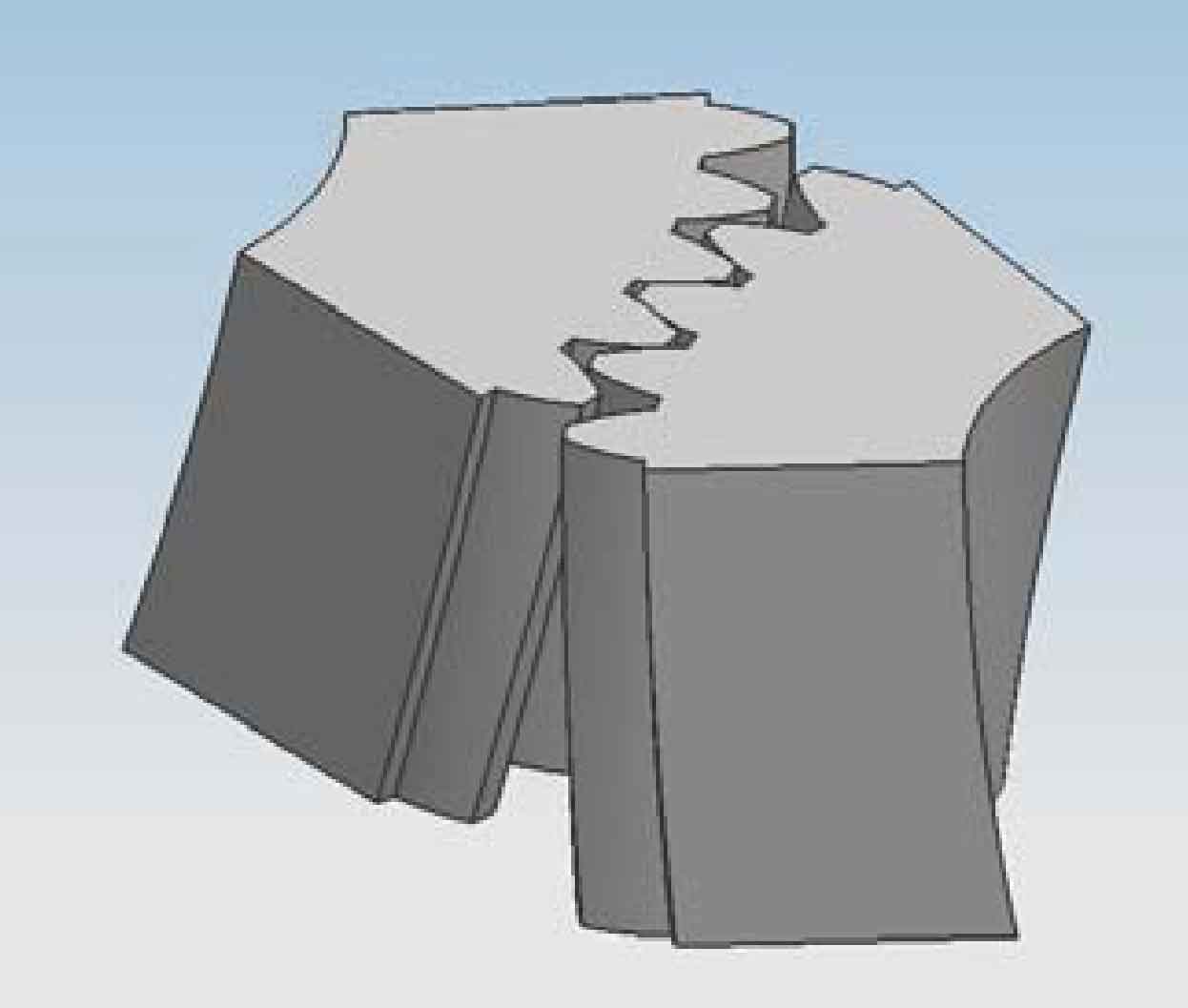

Compare and analyze the differences of helical gears in dynamic and static simulation, and use different forms of local helical gears for finite element contact analysis, as shown in Figure 1 and Figure 2 below.