The calculation of heat flow density and convection heat transfer coefficient will be used as the input heat source and boundary condition of the system dynamic temperature field analysis. The finite element method is used to simulate and analyze the numerical calculation results of the system dynamic temperature field. Since the material of bearing is inconsistent with that of gear and transmission shaft, the gear, input shaft and planetary shaft are made of structural steel, with a thermal conductivity of 60.5 W/(m2 ℃); The bearing is made of bearing steel, and its thermal conductivity is 46.6 W/(m2 ℃). Because there is inevitably an error between the results calculated by the theoretical method and the test measurement results, this error is caused by less consideration of the actual environment and boundary factors. With the test environment as a reference, improve the boundary conditions of the simulation link, further subdivide the planetary gear meshing process, reduce the error value between the analysis model and the test, and improve the applicability of the numerical analysis model.

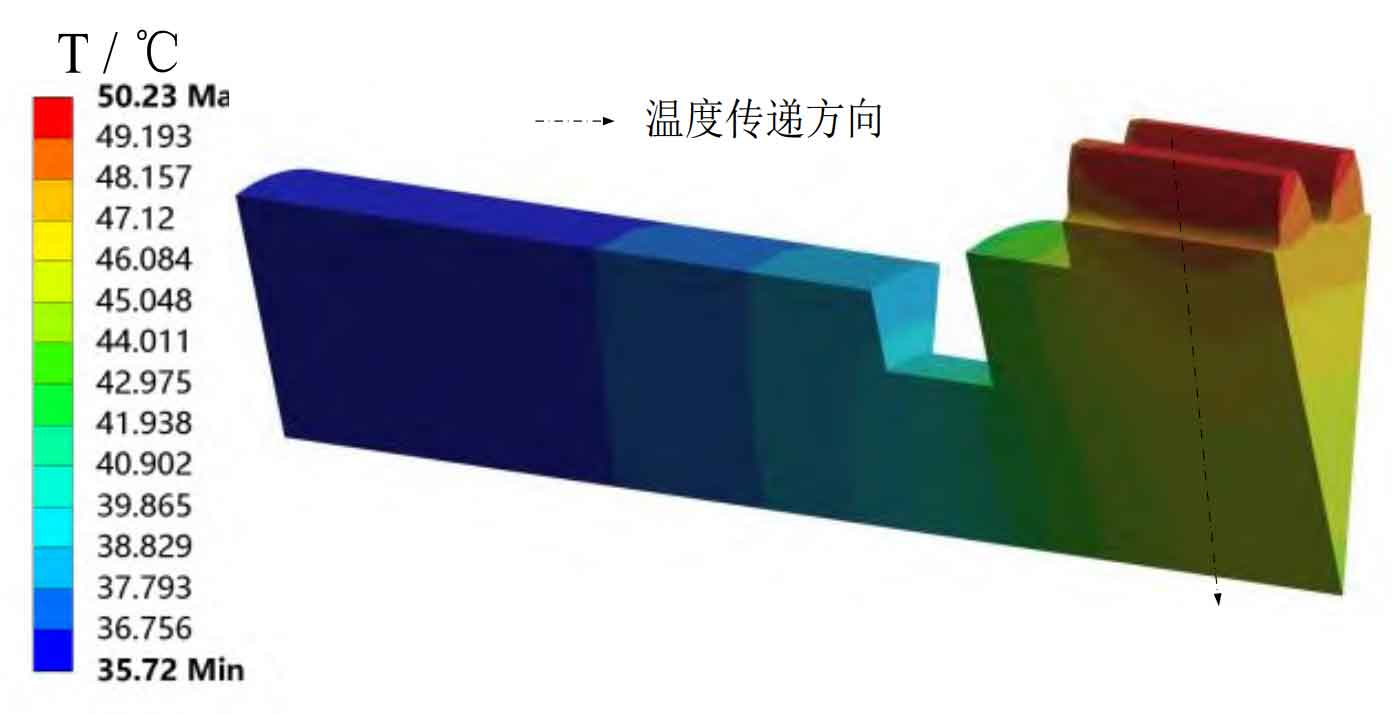

When analyzing the dynamic temperature field of the planetary gear system, the system model is divided into three parts: the sun gear – input shaft part, the planetary gear – bearing – planetary shaft part and the ring gear part, taking into account the factors such as the self transmission and revolution of the planetary gear during the operation process, and the constant change of the meshing position over time. The friction heat generated by each part is distributed according to the heat distribution principle, The temperature field of planetary gear system is indirectly analyzed by calculating the temperature distribution of three parts. When the average speed of the input shaft is 100 r/min and the load torque of the output end is 50 N · m, the temperature field of each part is shown in the figure.

During the operation of the planetary gear system, the temperature rise of the sun gear and the planetary gear is much higher than that of the ring gear, which is caused by the fact that the heat dissipation area of the sun gear is only 11/100 of the ring gear and 3/5 of the planetary gear, and the thermal load borne by the sun gear is 3.94 times of the ring gear and 1.84 times of the planetary gear. That is, the structure size has a greater impact on the convection heat transfer. The more compact the structure is, the smaller the heat dissipation area is, and the worse the heat dissipation effect of the lubricating oil is. As shown in Fig. (a), the maximum temperature of the gear surface is 50.32 ℃, and the temperature of the input shaft is higher only at the gear connection end.

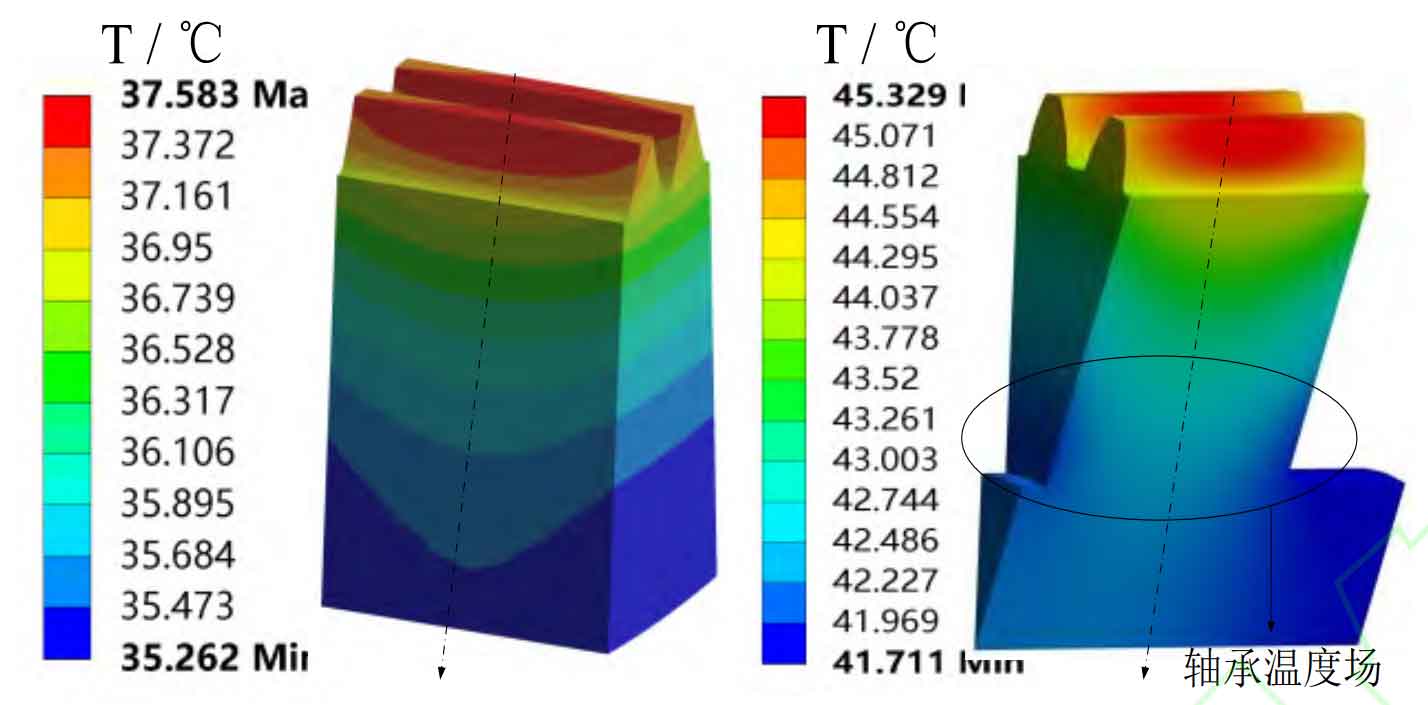

(c) Partial temperature field of planetary gear bearing planetary shaft

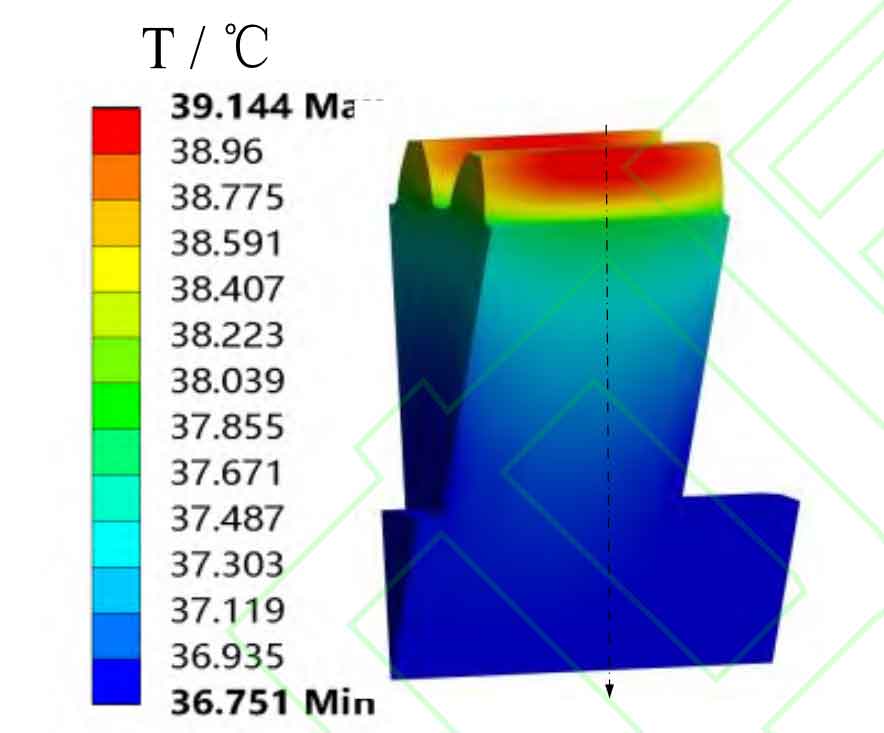

When considering the influence of bearing friction heat generation on the temperature rise of planetary gear system tooth surface, as shown in Fig. (c), the maximum temperature of planetary gear tooth surface is 45.33 ℃, while the maximum temperature of bearing surface is 42.86 ℃. As shown in Fig. (d), the temperature of the tooth surface has increased by about 6.2 ℃ compared with that without the influence of bearing heat generation. Therefore, the bearing friction heat generation has a great influence on the temperature field of the tooth surface. Due to the small size of the planetary gear and the heat generated by the friction between the gear and the bearing during operation, the overall temperature of this part is high.

The heat dissipation area of the gear ring is larger than that of other gears, and the friction heat generated when the sun gear is engaged with the planetary gear and the heat flow density distributed to the meshing surface of the gear ring are smaller. When the gear ring reaches the steady-state temperature, as shown in the temperature field diagram of the gear ring in Fig. (b), the temperature difference between the meshing surface and the gear end face is 2.32 ℃. The high temperature area of the gear surface appears near the top of the gear surface. When the planetary gear and the gear ring mesh, the relative sliding speed is relatively high during the process of exiting the meshing state.