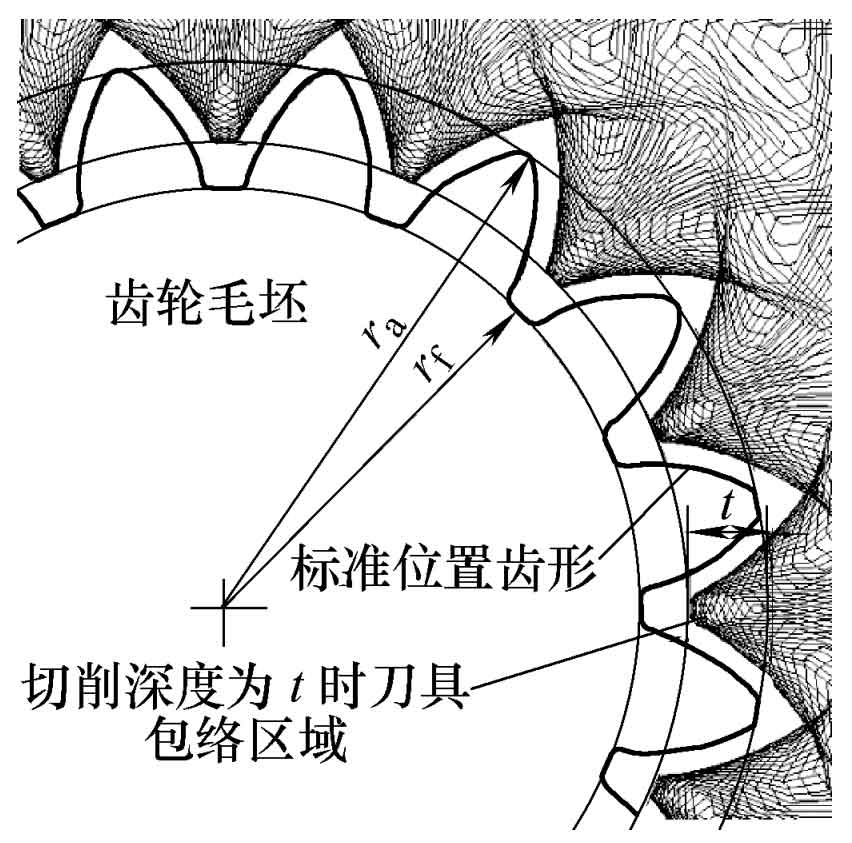

The machining principle of gear shaper is the generation method, that is, the tool and the involute gear blank conduct synchronous meshing movement, and the involute gear tooth profile is formed along the curve enveloped by the cutting edge of the tool. When the cutting depth is t, the tooth profile is shown in Figure 1.

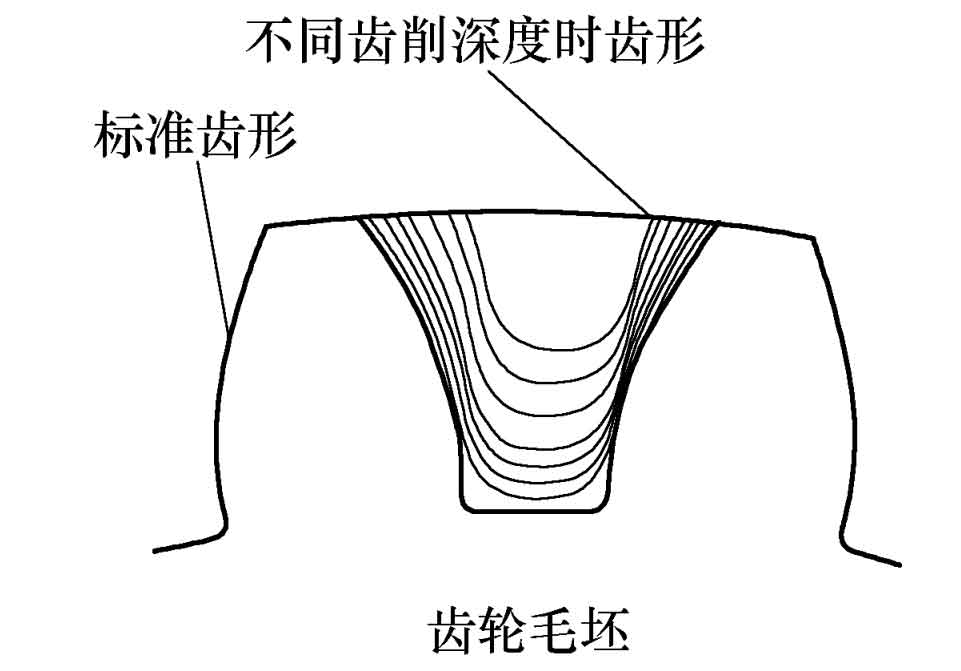

The tool envelope curve of gear shaper machining with different feed depth is shown in Figure 2. It can be seen from the figure that the cutting area of the tool changes obviously with the different feed depth. Considering that other parameters remain unchanged, the area change means that the cutting force during tool cutting changes. Further, it can be seen that assuming that the involute gear is processed in two feeds, The area removed for the first time and the second time changes greatly due to the different depth settings of the feed, resulting in the increase of the cutting force, which is not conducive to the cutting of the machine tool. Therefore, it is very important to set a reasonable feed depth.