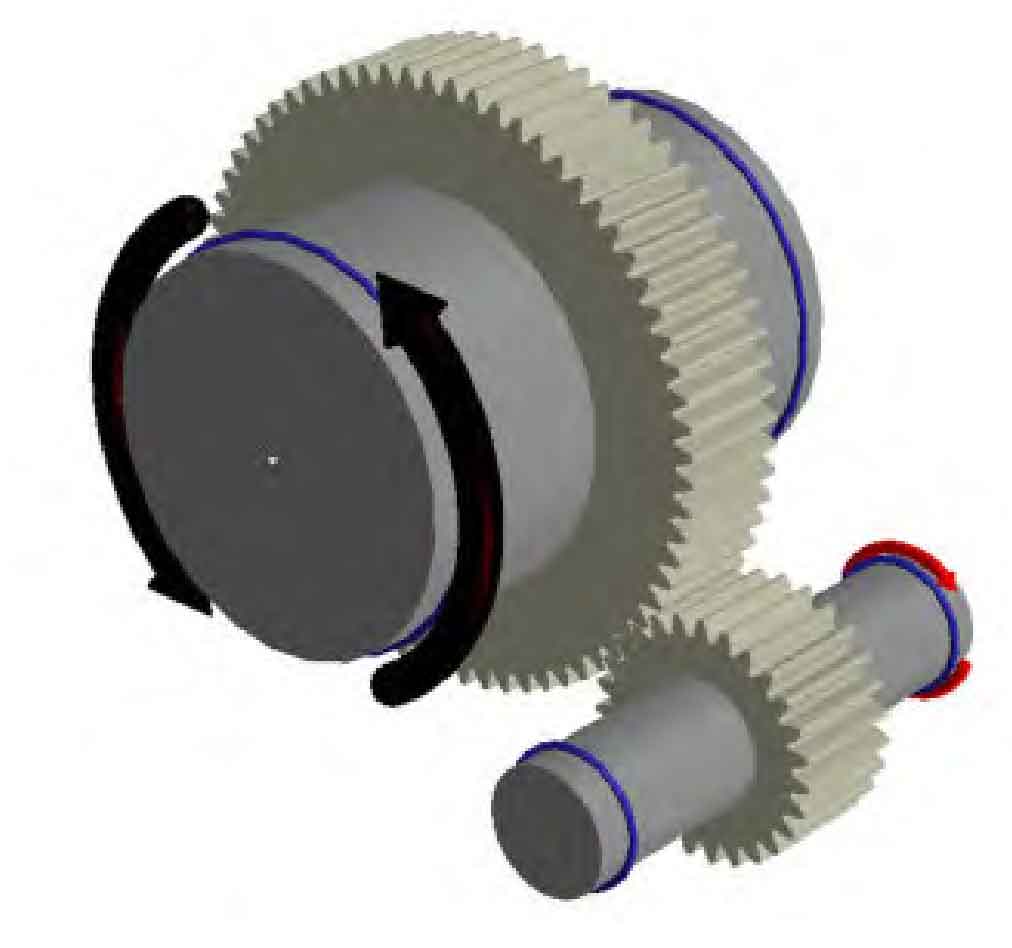

1. Establishment of a Romax spur gear meshing model

After defining the size and assembly parameters of parts in Romax, three-dimensional parametric modeling of components such as shafts, gears, and bearings can be directly achieved. Then, material properties can be defined, and power flow can be applied to obtain a complete Romax spur gear meshing model, as shown in Figure 1.

2. Simulation and Comparison of Transmission Errors

Transmission error is related to the vibration and noise of the transmission, and is an important indicator for testing the effect of shape modification. There is a professional spur gear modification module in Romax software, which can define different modification parameters for spur gears and solve the variation curve of spur gear transmission error under different modification amounts.

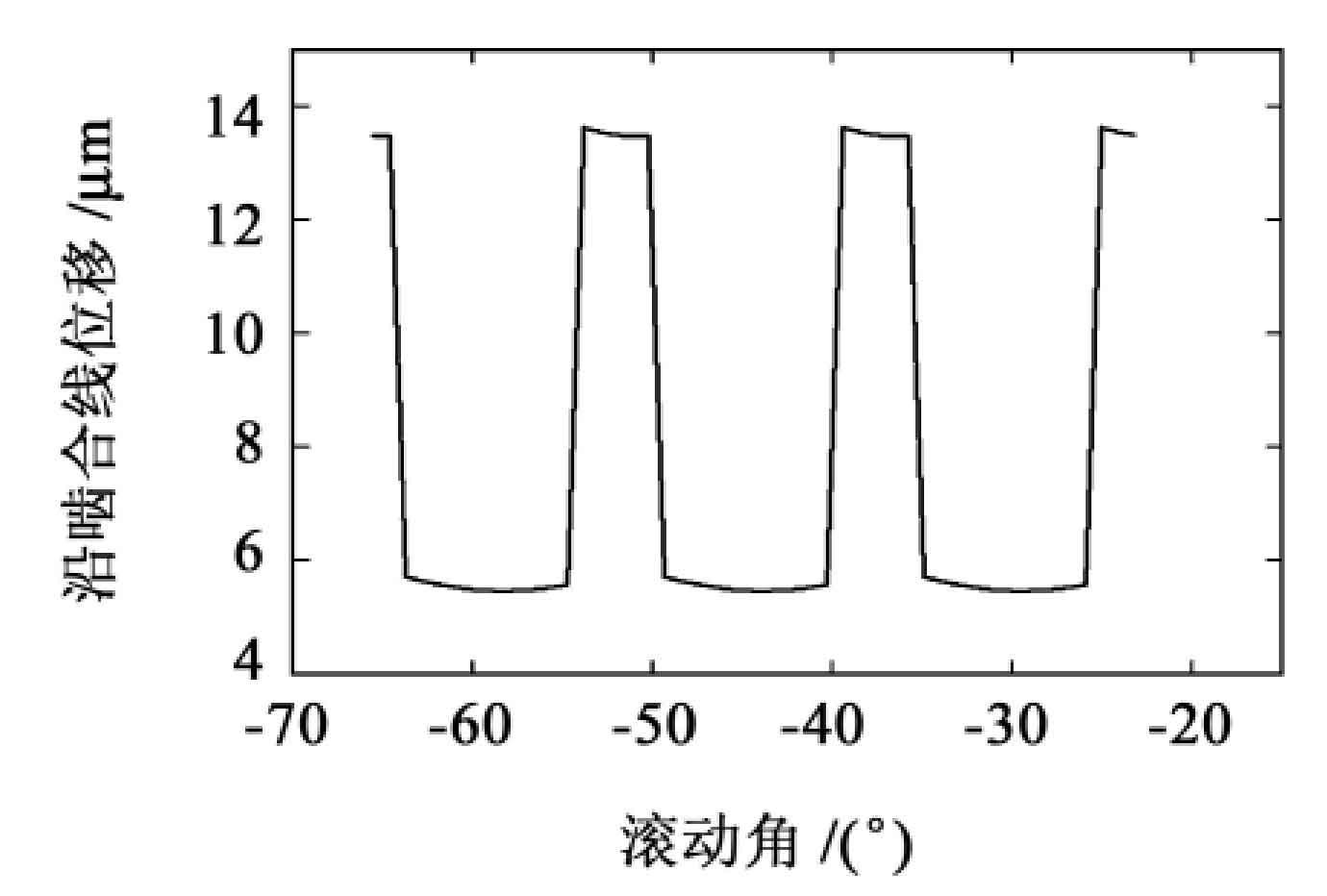

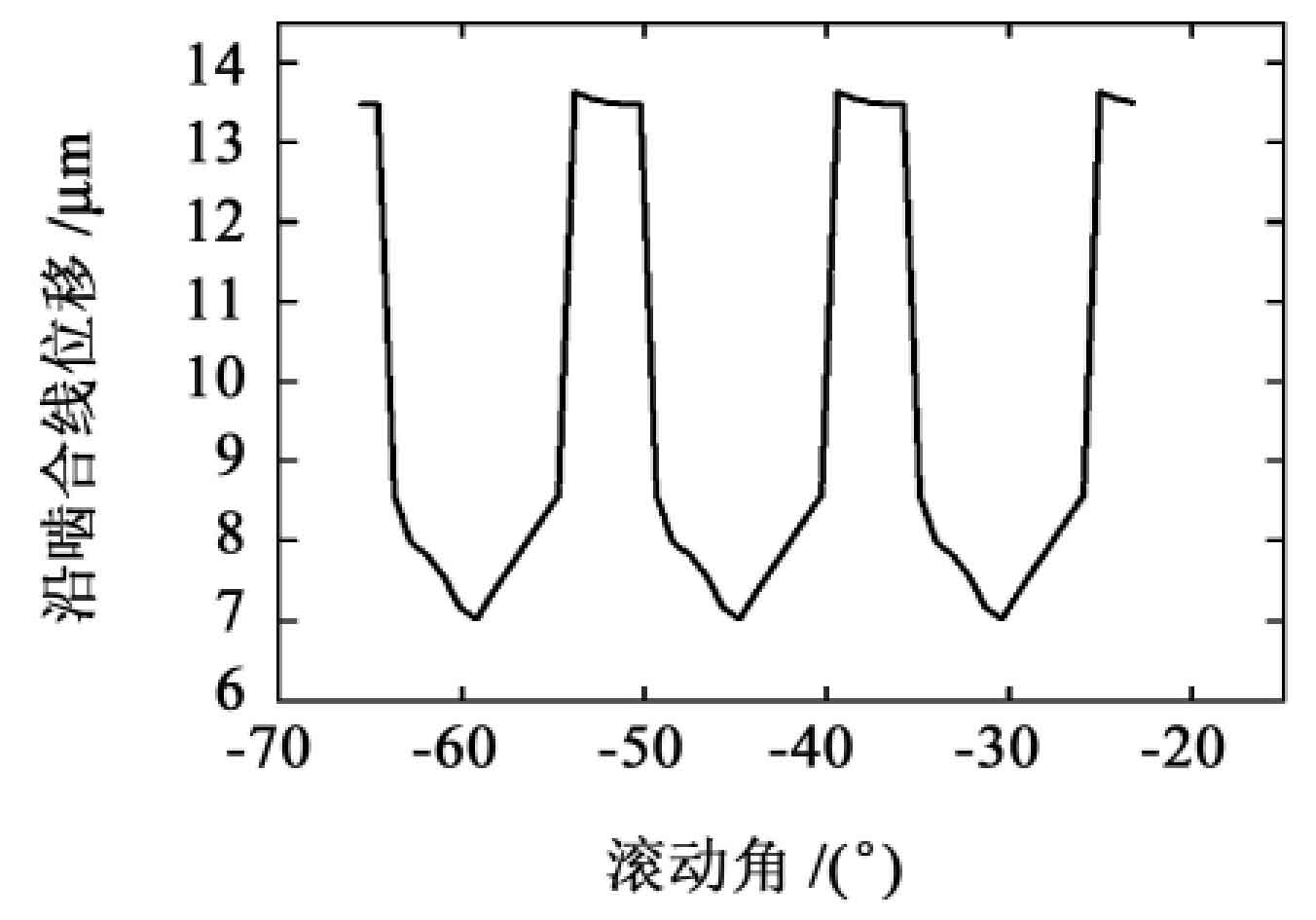

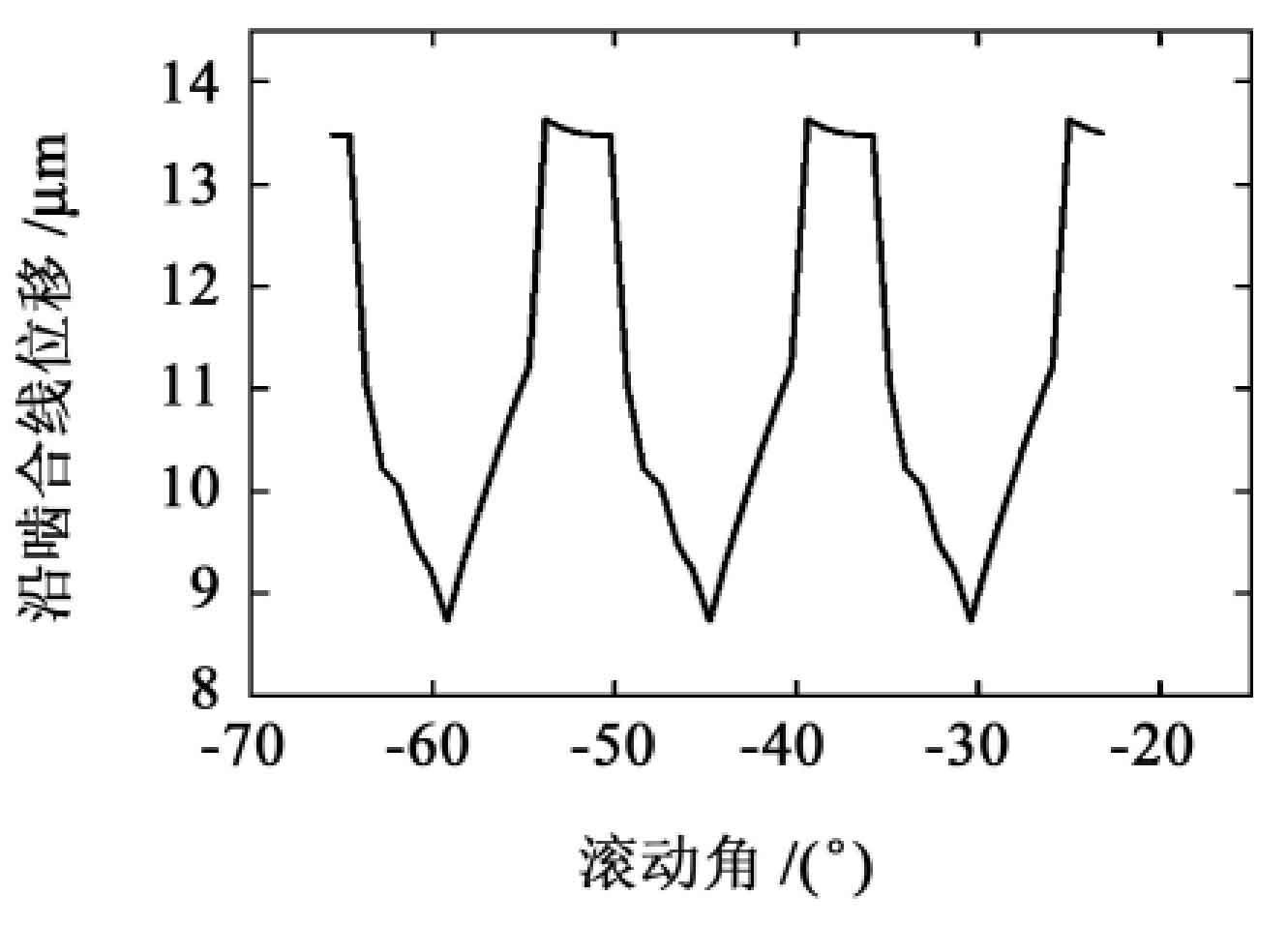

Simulate the transmission error of standard spur gears, spur gears modified according to ISO method, and spur gears modified according to method, and the results are shown in Figures 2 to 4, respectively.

The transmission errors of different spur gear pairs obtained from Figures 2 to 4 are shown in the table.

| Modification amount/µm | Transmission error/µm | |

| Standard gear | 0 | 8.17 |

| ISO shaping | 21.13 | 6.60 |

| EHL shaping | 33.18 | 4.73 |

From the table, it can be seen that the transmission error of the spur gear before the modification is 8 17 µm; After the modification amount calculated by the ISO method, the transmission error of the spur gear is significantly reduced, with a transmission error of 6 6 µ m, reduced by 19% compared to before shaping 22%; After modifying the stiffness of the elastohydrodynamic friction pair, the transmission error is further reduced, with a transmission error of 4 73 µ m, reduced by 42 11%, reduced by 28.3% compared to the ISO method, and the shape modification effect is more significant. Further explain that the influence of elastohydrodynamic lubrication on the modification of spur gears cannot be ignored.