Digital gear tooth surface design, analysis and manufacturing is the trend of gear development. Through digital means, gear production efficiency can be improved and quality control is convenient. Dong Xuezhu proposed a new method to generate a corresponding network on both sides of the gear tooth. The shape of the gear tooth surface is described by using the network curve and the change of the tooth thickness. The tooth surface interference is checked by calculating the clearance of each point of the gear tooth surface when the gear is engaged at different positions, and can be used to study the TCA of the real tooth surface with error or deformation; Dong Xuezhu also generated a mesh on the tooth surface, established a movable frame, and proposed a zero clearance method for gear tooth surface meshing analysis, which laid a foundation for the study of real tooth surface meshing theory. Zhang y superimposed the theoretical tooth surface and the error surface to obtain the real tooth surface of the involute hypoid gear. Jiang Jinke used the same method to study the fitting of the actual tooth surface of the modified helical gear, and carried out the tooth contact analysis of the actual tooth surface. However, the calculation process of the actual tooth surface expressed by the superposition of the theoretical tooth surface and the error surface was cumbersome, and finally he could not leave the theoretical tooth surface. Based on the coordinates of the mesh nodes of the tooth surface measured by the coordinate measuring machine, sun Dianzhu systematically studied the meshing theory of the real tooth surface with errors and heat treatment deformation. Using the theory of surface modeling and computer aided geometric design (CAGD) and the classical gear meshing theory, he established a geometric oriented and strictly mathematical supported mathematical model of the real tooth surface, A set of new theory and method of real tooth surface meshing analysis suitable for various gear transmission forms are proposed.

By establishing the interference criterion to test the real tooth surface, Ma Zhenqun uses a series of continuously changing cylindrical surfaces to intercept the meshing tooth surface, and obtains a family of instantaneous contact lines, so as to analyze the tooth surface contact in the whole meshing process. Wang Zhonghou introduced the imaginary full conjugate tooth surface as the reference tooth surface, divided the contact line on the reference gear tooth surface into topological meshes, introduced the concept of digital synthetic error, constructed the digital real tooth surface of spiral bevel gear containing tooth profile error and installation error, and proposed a TCA method of spiral bevel gear based on high-precision digital real tooth surface, The feasibility and effectiveness of this method are verified by comparing with the analysis results of Gleason TCA software and the wear test results of gear tooth surface. Su Zhijian calculated the discrete gear tooth surface points of hypoid gear through simulation program, and then fitted the gear tooth surface with non-uniform rational B-spline (NURBS), which solved the problem of designing unknown gear tooth surface under the condition of known NURBS representation of gear tooth surface, tooth surface contact trace and transmission ratio function, In TCA method, the condition that the angle between the line between two calculation points and the normal at one of them is zero is proposed to replace the condition of normal coincidence. Wang Yanzhong et al. Used cubic B-spline function to fit the sampling points, obtained the gear tooth surface equation, established the gear tooth surface contact analysis method based on discrete point description, and transformed the TCA model into a constrained minimum optimization problem. This method is not easy to diverge, and there are not many restrictions on the selection of the initial point.

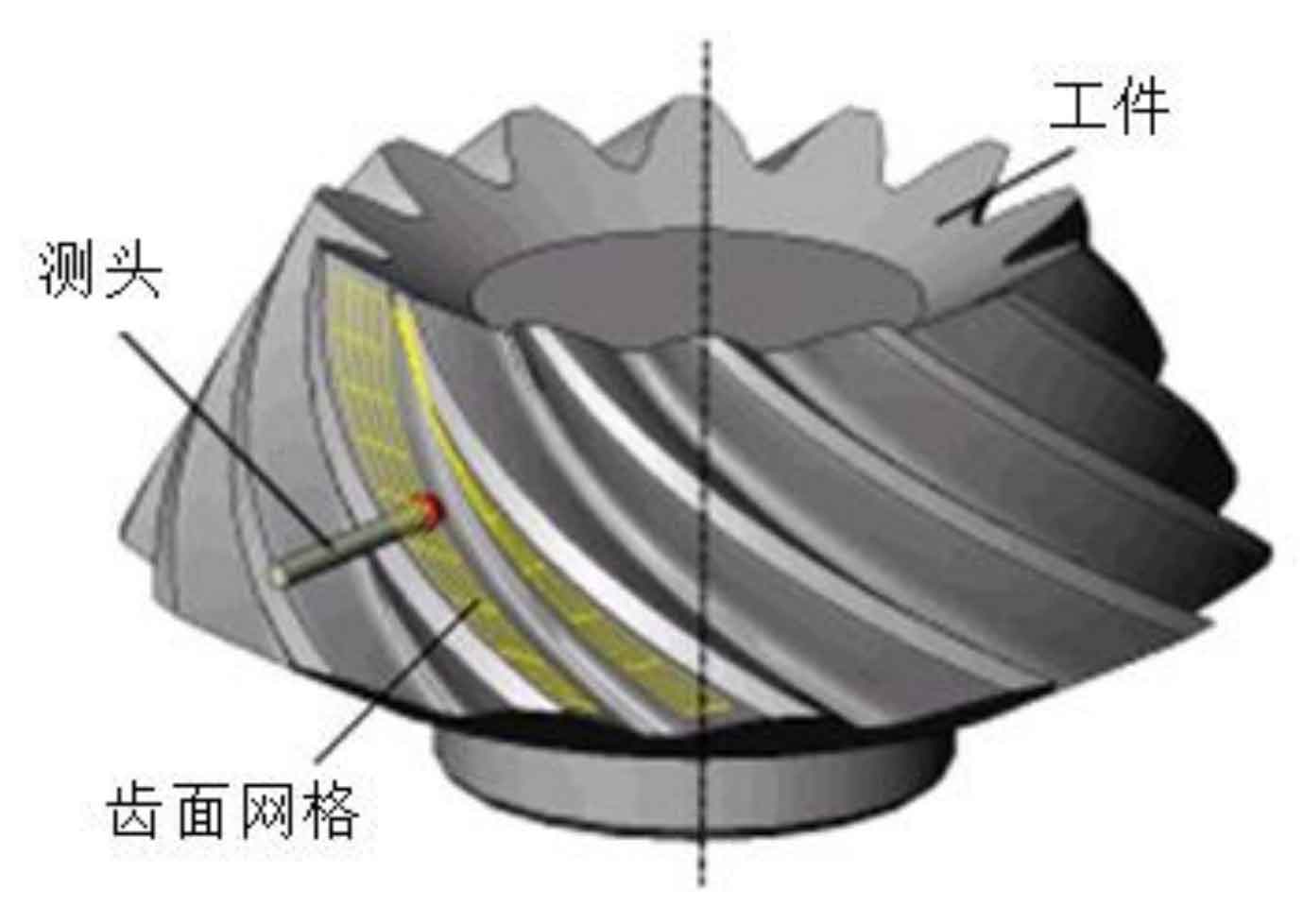

Under the condition that the sampling points of gear tooth surface measurement are known, Li Xiaoqing established the mathematical model of spiral bevel gear tooth surface fitting by using differential geometry and the principle of Ferguson parameter spline curve. According to the compound shape optimization method and conjugate theory, he calculated the extreme value, quickly solved the contact point of gear pair fitting gear tooth surface by changing the definition domain, and used the V-H contact area adjustment method, The algorithm for solving the contact mark and transmission error of meshing gear tooth surface is studied. Zhang Weiqing and Wang Xiaolin also studied the tooth surface fitting and contact visualization of bevel gears and hypoid gears respectively. Fang Zongde and Zhang Junhui proposed a digital roll inspection method for spiral bevel gears, obtained the contact marks and transmission errors of the actual gear tooth surface, analyzed the difference in meshing performance between the actual gear tooth surface and the theoretical gear tooth surface, and solved the problem that the evaluation criteria of spiral bevel gears design and actual inspection are not unified due to machining errors. Su Jinzhan further considered the normal vector of discrete points, optimized the control vertices, realized the modification of the geometric characteristics of the digital gear tooth surface, established the mesh simulation analysis model of the digital gear tooth surface, and carried out the impression roll inspection test. In cycloid gear, there are few reports on actual gear tooth surface fitting based on measurement and TCA.

In traditional gear manufacturing, before gear cutting, the transmission error and contact mark are evaluated according to the TCA of the theoretical gear surface, and the machining parameters are modified accordingly. Then the gear cutting is completed, and then the meshing quality is verified by the rolling inspection test of the actual gear surface. On the one hand, there is a problem that the evaluation benchmark is inconsistent when the theoretical gear surface is used for design simulation but the actual gear surface is used for rolling inspection; On the other hand, it needs many repetitions to obtain satisfactory meshing performance, which is time-consuming, labor-intensive and too dependent on the experience of technicians. Moreover, the roll inspection test can only obtain the meshing marks of the actual gear tooth surface, but does not reflect the transmission error information. A large number of studies have shown that the transmission error directly affects the dynamic performance of the gear pair and is an important cause of vibration and noise. Therefore, how to comprehensively reflect the meshing performance of the actual gear surface is particularly important.