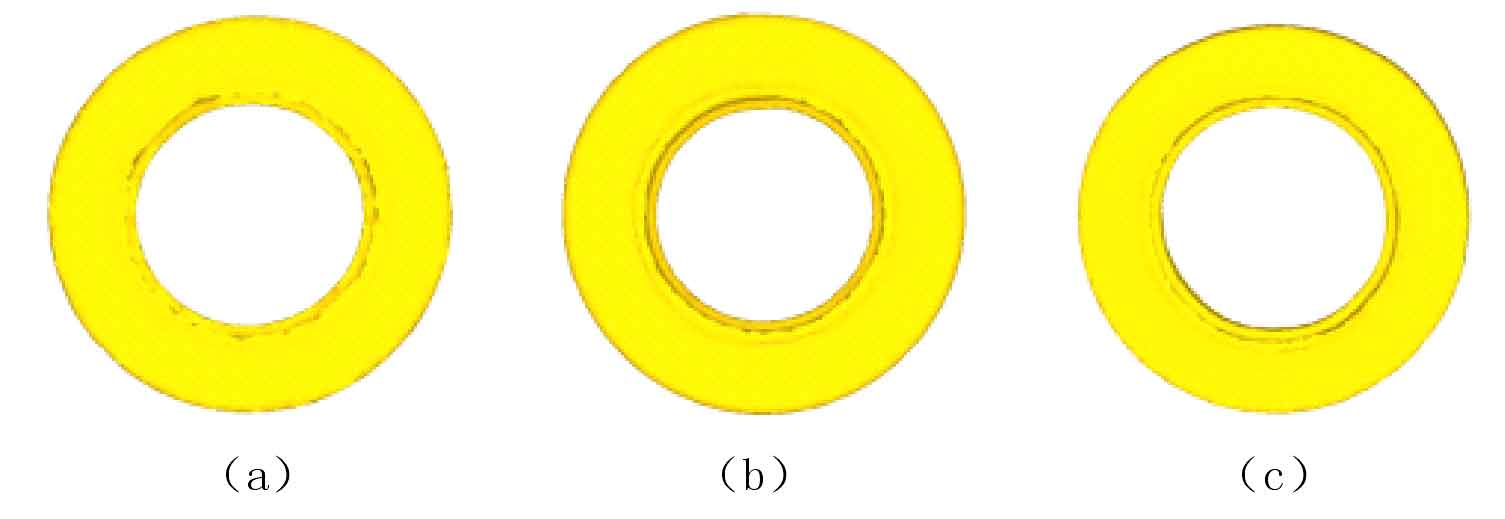

The formed spiral bevel gear blank is formed by ring rolling based on the ring blank. Through numerical simulation of ring rolling forming process, the final geometric shape of the formed spiral bevel gear blank is shown in the figure.

From the end view, the forming quality of figure B and C is better than that of figure A. There are different degrees of flash at the inner hole of the upper end of figure a, and the forming quality is poor. Therefore, the forming quality of spiral bevel gear blank in scheme B and C is better than that in scheme a.

| Programme | a | b | c |

| Outer diameter (mm) | 175.5 | 179.7 | 180 |

| Inner diameter (mm) | 109.1 | 110.8 | 111.3 |

| Height (mm) | 20.2 | 20.5 | 21 |

The specific dimensions of spiral bevel gear blank formed by the three schemes are shown in the table. The forming dimensions of bevel gear blank in scheme a in the table are not within the required dimensional tolerance range of formed forgings, and schemes B and C meet the dimensional requirements.