The blank size of spiral bevel gear refers to the specific size of the material before the pier is rough, that is, before the initial processing. In order to determine the size of the original blank, we should first accurately calculate the volume of the formed part according to the appearance shape, specific size and processing method of the formed forging, and then calculate the end face area and blank length according to the section shape. The size calculation of blank and ring blank is based on the forging drawing of spiral bevel gear blank formed by ring rolling process. On this basis, the results are obtained through relevant calculation. The forging drawing of spiral bevel gear blank of ring rolling process is shown in the figure.

1.Dimension calculation of spiral bevel gear blank

(1) Blank diameter DP of spiral bevel gear

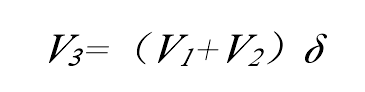

The total volume V of spiral bevel gear blank is composed of three parts. V1 is the volume of forging, V2 is the volume of skin, and V3 is the volume of fire consumption. The calculation formula is:

Where δ It is the fire consumption coefficient, which is obtained by referring to Table 3.1. Since the spiral bevel gear blank is heated in a heating furnace, it is selected δ= 1%。

Using CATIA three-dimensional modeling and volume measurement tools, the volume of forging V1 = 333600mm3 and that of skin V2 = 22670.8mm3 are obtained directly.

The calculated fire consumption volume V3 = 3562.708mm3, and the total volume of spiral bevel gear blank v = 359833.5mm3.

As the spiral bevel gear blank belongs to round cake forging, the selection formula is:

After substituting the above data into the formula, the final DP is 63.14mm, and the DP is 65mm according to the standard specification.

(2) Blank length LP of spiral bevel gear

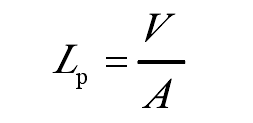

Calculation formula of blanking length:

Where a is the cross-sectional area of spiral bevel gear blank, and LP is 108mm by substituting the diameter PD into formula 3-6.

Finally, the bar specification is selected as Ф sixty-five × The final forging mass of bevel gear ring = 1082.6kg, and the final forging mass of bevel gear ring = 1082.6m.

2.Dimension calculation of spiral bevel gear blank

Pre forging is the previous process of the ring rolling forming of the driven spiral bevel gear blank of the automobile rear axle. In order to ensure the smooth rolling of the ring, the preform of the spiral bevel gear must be accurately calculated to form a ring that meets the quality requirements without wasting raw materials. Therefore, the calculation of the spiral bevel gear blank before ring rolling is one of the important factors to ensure the quality and accuracy of the forging.

As the spiral bevel gear blank belongs to the inner step spiral bevel gear blank, which is different from the calculation of simple rectangular section parts, the specific calculation process is as follows:

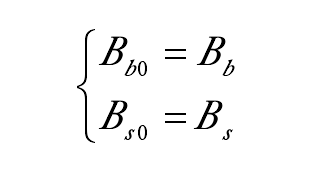

(1) Axial dimension formula of spiral bevel gear blank:

Where, bb0 and bs0 are the axial size of large hole and small hole of spiral bevel gear blank, and BB and BS are the axial size of large hole and small hole of ring forging.

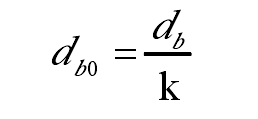

(2) Calculation of large hole diameter of spiral bevel gear blank:

Db0 and DB are the large hole diameter of spiral bevel gear blank and forging.

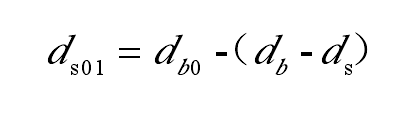

(3) The hole diameter of spiral bevel gear blank is preliminarily determined, and the calculation formula is:

DS01 and DS are the small hole diameter of spiral bevel gear blank and forging.

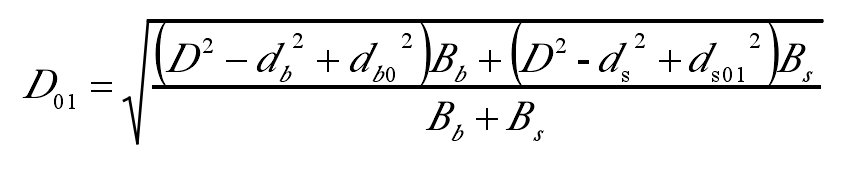

(4) According to the principle of constant volume, the outer diameter of spiral bevel gear blank is preliminarily calculated:

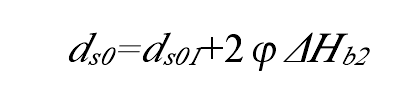

(5) Calculate the small hole diameter of spiral bevel gear blank:

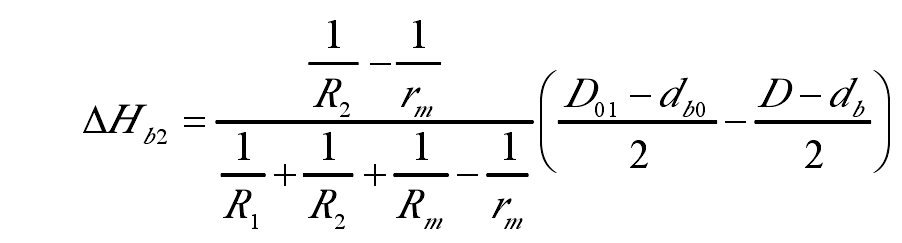

Where ϕ Is the correction coefficient, and the value is between 1 and 2, Δ HB2 is the feed rate of the inner surface at the large hole of the ring, and the calculation formula is:

Where R1 and R2 are the radius of the driving roll and the radius of the core roll corresponding to the large hole of the ring, RM is the average value of the outer radius of the ring forging and the spiral bevel gear blank, and RM is the average value of the inner radius of the ring forging and the spiral bevel gear blank Δ Hb2=4.5。

(6) Determine the diameter of spiral bevel gear blank

The outer diameter of spiral bevel gear blank can be calculated by substituting DS0 instead of DS01 and d0 instead of D01 into the formula.

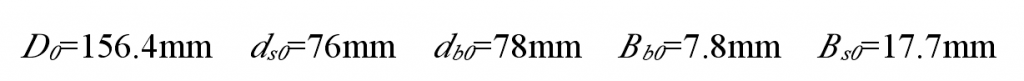

After calculation:

The ring rolling ratio of rectangular ring is between 1.5 and 5, while the ring rolling ratio of gear blank ring is generally not too large, between 1.3 and 1.9. Considering that the specific size of forging is not large, the ring rolling ratio k = 1.55 is taken.