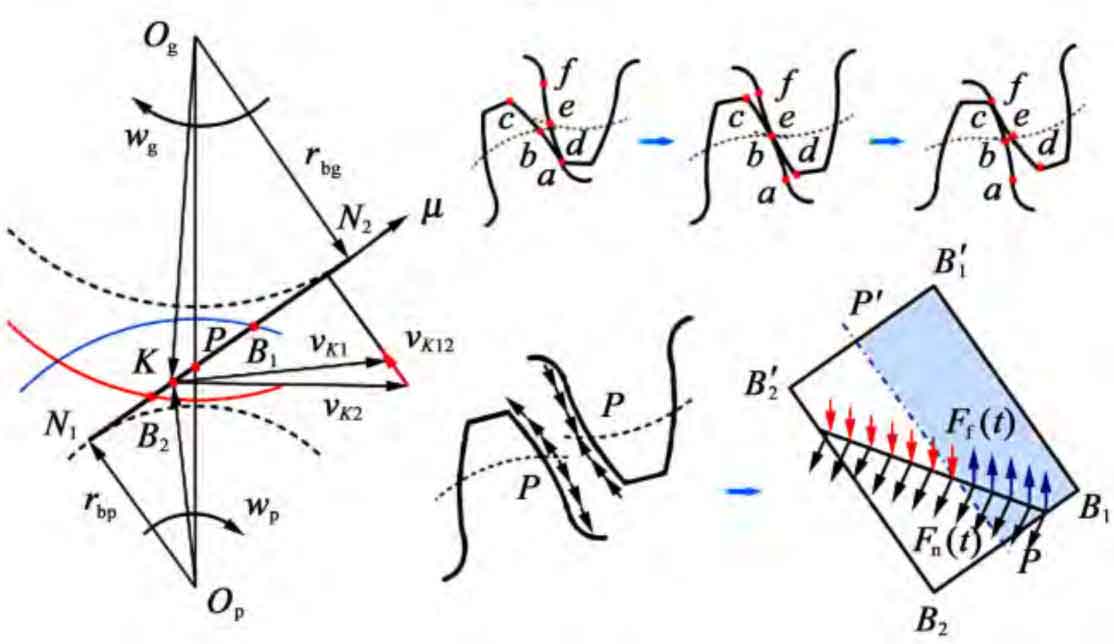

According to the meshing principle of helical gears, when a pair of helical gears enter into meshing and exit from meshing, the surface of gear teeth has relative sliding and rolling. The meshing process of helical gear end face is shown in the figure. When the driven and driven wheels of the driving wheel rotate, the meshing point on the driving wheel moves continuously from the root of the tooth to the top of the tooth, the meshing radius increases gradually, and the linear speed increases gradually; The engagement point on the driven gear moves continuously from the top of the tooth to the root of the tooth, the engagement radius decreases gradually, and the linear speed decreases gradually. The speed difference between the two gear tooth surfaces at the meshing point leads to relative sliding between them.

At the initial meshing stage, the meshing point K is located in the B2P area, the speed of the meshing point on the driving gear is less than the speed of the meshing point on the driven gear, and the relative sliding speed of the tooth surface vK12<0. At this time, the driving gear teeth make relative sliding along the direction of the driven gear teeth facing the driven gear tooth root; At the node, point K coincides with point P, the speed of the meshing point on the two helical gears is equal, vK12=0, at this time, the two helical gears perform pure rolling; In the disengagement phase, point K is located in the PB1 area. The speed of the engaging point on the driving gear is greater than that of the engaging point on the driven gear, vK12>0. At this time, the teeth of the driving gear make relative slip along the direction of the driven gear teeth facing the top of the driven gear.

According to the analysis of the relative sliding law of the helical gear meshing tooth surface, the relative sliding speed of the meshing point on the tooth surface will reverse before and after the meshing point K passes the node P, resulting in the change of the friction direction on both sides of the meshing tooth surface pitch line PP ‘.