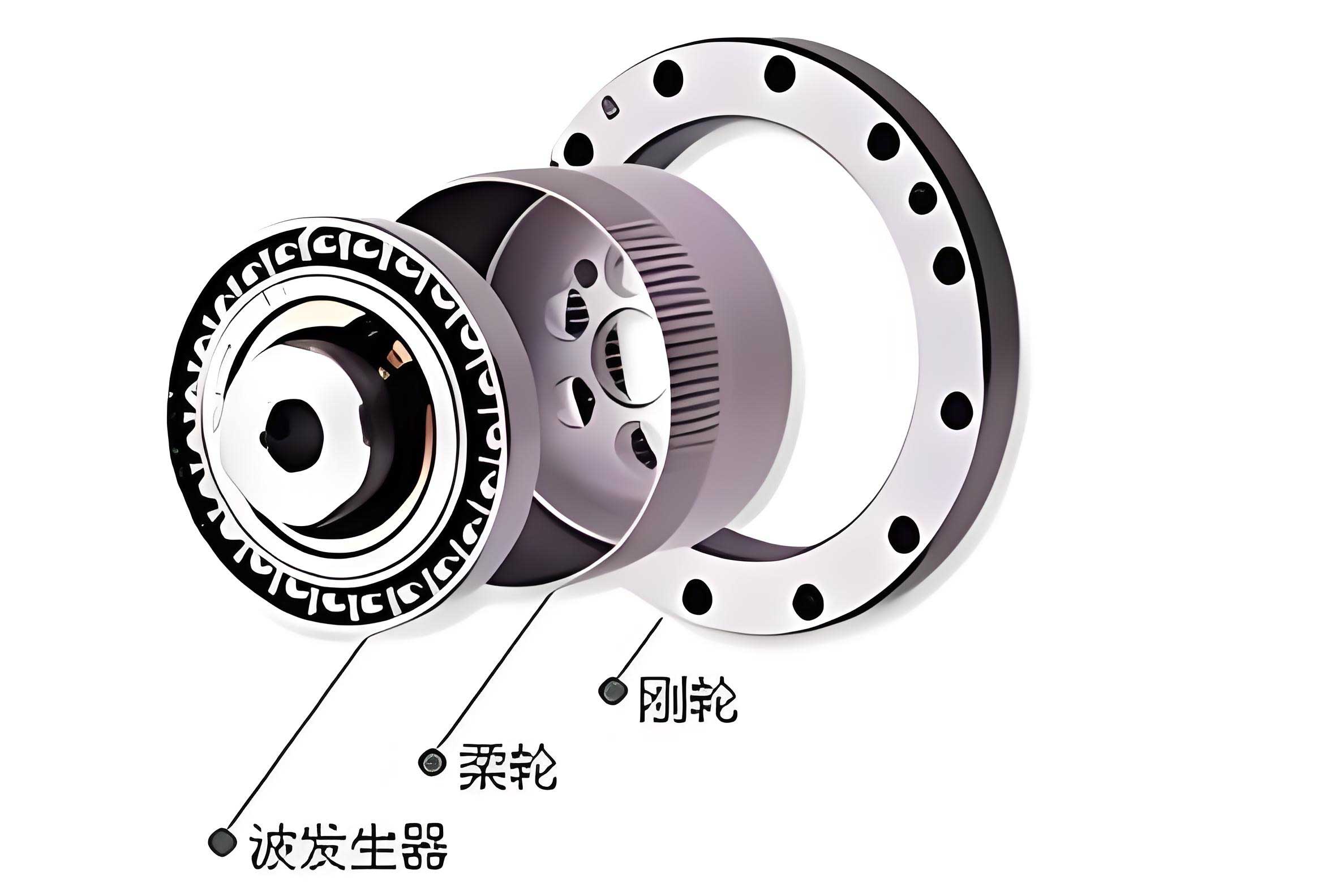

The relentless advancement of space technology and deep-space exploration continuously pushes the boundaries of engineering, demanding ever-greater reliability from critical spacecraft mechanisms. Among these, the strain wave gear, also known as a harmonic drive, is a pivotal component. Its unique operating principle, relying on the controlled elastic deformation of a flexible spline to mesh with a rigid circular spline, grants it exceptional advantages: a high transmission ratio, compact size, high positional accuracy, and zero-backlash operation. These qualities make it indispensable in precision mechanisms such as antenna pointing systems, robotic arms, and solar array drives on satellites and space stations.

However, this very principle of elastic deformation induces complex contact conditions and significant sliding at the tooth interfaces during meshing. In the unforgiving environment of space—characterized by ultra-high vacuum, extreme temperature fluctuations (from cryogenic to elevated temperatures), and atomic oxygen—traditional lubrication methods face severe challenges. Liquid lubricants like perfluoropolyethers (PFPE) or multiply alkylated cyclopentanes (MACs), while effective in a narrower range, suffer from drastic viscosity changes. At cryogenic temperatures, they can become semi-solid, leading to high startup and running torques, potential starvation in the contact zone, and catastrophic failure. Consequently, the quest for a robust lubrication solution that maintains performance across this wide environmental spectrum is paramount.

Solid lubrication coatings have emerged as a highly promising avenue. Unlike their liquid counterparts, these coatings offer a stable, transferable lubricating film directly on the contacting surfaces. Their tribological properties are less susceptible to vacuum outgassing or thermal viscosity swings, providing a more predictable and potentially longer service life. This article delves into the systematic evaluation of advanced solid lubrication coatings, specifically developed and optimized for the strain wave gear application in simulated harsh space conditions. The focus is on their fundamental tribological behavior, environmental stability, and, most critically, their resulting performance in actual strain wave gear reducers concerning transmission accuracy and efficiency across a wide temperature range.

Fundamental Principles and Lubrication Challenges in Strain Wave Gears

The core of a strain wave gear system consists of three key components: a wave generator (an elliptical bearing assembly), a flexible spline (a thin-walled cup with external teeth), and a circular spline (a rigid ring with internal teeth, having a slightly different number of teeth). As the wave generator rotates, it deflects the flexible spline, causing its teeth to progressively engage and disengage with those of the circular spline. This action results in a slow relative rotation between the splines. The kinematic relationship is given by:

$$

\text{Transmission Ratio} = -\frac{N_f}{N_c – N_f}

$$

where \(N_c\) is the number of teeth on the circular spline and \(N_f\) is the number of teeth on the flexible spline. The negative sign indicates opposite rotation directions.

This meshing process is not pure rolling; it involves a significant amount of sliding and complex multi-tooth contact. The contact stress \(\sigma_c\) at the tooth interface can be approximated by Hertzian contact theory for conforming surfaces, but is heavily influenced by the dynamic flexing of the spline:

$$

\sigma_c \propto \sqrt{\frac{F E^*}{R L}}

$$

where \(F\) is the normal load, \(E^*\) is the effective elastic modulus, \(R\) is the effective radius of curvature, and \(L\) is the contact length. The repeated high-stress sliding under vacuum conditions, without an effective lubricant, leads to rapid wear, increased friction, degradation of transmission precision (increased backlash and error), and ultimately, seizure. The challenge is compounded by the need for the lubricant to adhere to both steel substrates (typically high-strength alloys for the flexible spline and a gear steel for the circular spline) and to perform from -100°C to over +100°C.

Development and Screening of Solid Lubrication Coatings

Our approach focused on two families of coatings applied via Physical Vapor Deposition (PVD): Molybdenum Disulfide (MoS2)-based coatings and Diamond-Like Carbon (DLC) coatings. The substrate materials were representative alloys: 40CrNiMoA for the flexible spline and 20Cr13 for the circular spline.

1. Coating Architectures and Basic Properties

Three types of MoS2-based coatings were engineered:

- MoS2/Zn Superlattice Coating: A nano-layered structure alternating MoS2 and Zinc layers to inhibit columnar growth and provide low shear strength.

- TiN+MoS2/Zn Multilayer Coating: Incorporates a hard Titanium Nitride (TiN) interlayer to enhance load-bearing capacity and adhesion before depositing the MoS2/Zn superlattice.

- MOSTP Coating (MoS2/Pb-Ti Nanocomposite): A co-sputtered coating where Pb-Ti nano-particles are embedded in a MoS2 matrix, aiming for improved environmental stability and toughness.

A hydrogenated DLC coating was also developed, featuring a Cr adhesion layer, a WC interlayer, and a gradient transition to the DLC top layer.

Scanning Electron Microscopy confirmed all coatings were dense, uniform, and approximately 2.5 μm thick. X-ray Diffraction showed the MoS2-based coatings had a strong basal (002) plane orientation, crucial for low friction, while the DLC was amorphous. Nanoindentation revealed the superior hardness of DLC (~29.5 GPa) compared to the softer MoS2-based coatings (~6-8 GPa), as summarized in Table 1.

| Coating Type | Architecture | Thickness (μm) | Hardness (GPa) | Elastic Modulus (GPa) | Key Feature |

|---|---|---|---|---|---|

| MoS2/Zn | Superlattice | ~2.2 | 7.5 | 98.5 | Ultra-low friction at cryo-temps |

| TiN+MoS2/Zn | Hard Layer + Superlattice | ~2.2 | 7.7 | 105.7 | Enhanced load support |

| MOSTP | Nanocomposite (MoS2/Pb-Ti) | ~2.6 | 6.0 | 71.4 | Improved environmental stability |

| DLC | Graded a-C:H | ~2.4 | 29.5 | 307.8 | High hardness, wear resistance |

2. Vacuum Tribological Performance at Extreme Temperatures

Initial screening was performed using a ball-on-disk tribometer under high vacuum (<10-3 Pa) at +100°C and -100°C. A steel ball (40CrNiMoA) slid against coated disks (20Cr13 substrate).

The results were striking. At -100°C, the MoS2/Zn coating exhibited superlubricious behavior with a friction coefficient (μ) as low as 0.007. The TiN+MoS2/Zn also performed excellently (μ ~0.009). The MOSTP coating had a higher but still good μ of ~0.027. At +100°C, friction increased for all MoS2-based coatings, with TiN+MoS2/Zn showing the best combination of low friction (μ~0.020) and low wear rate. The DLC coating, while very hard, displayed higher and more unstable friction in pure vacuum against steel. Crucially, the wear rate \(W\) was calculated from cross-sectional profilometry:

$$

W = \frac{V}{N \cdot L}

$$

where \(V\) is the wear volume (m3), \(N\) is the normal load (N), and \(L\) is the sliding distance (m). The TiN+MoS2/Zn coating showed wear rates an order of magnitude lower than the pure MoS2/Zn at high temperature, proving the benefit of the hard interlayer.

| Coating | Temp. (°C) | Avg. Friction Coeff. (μ) | Wear Rate (10-7 mm³/N·m) |

|---|---|---|---|

| MoS2/Zn | +100 | 0.032 | 12.0 |

| TiN+MoS2/Zn | +100 | 0.020 | 4.0 |

| MOSTP | +100 | 0.035 | 7.7 |

| MoS2/Zn | -100 | 0.007 | 16.0 |

| TiN+MoS2/Zn | -100 | 0.009 | 3.1 |

| MOSTP | -100 | 0.027 | 7.8 |

3. Coating Pair Compatibility and Environmental Stability

For a strain wave gear, the interaction is between the flexible spline and circular spline coatings. We investigated pairing DLC with MoS2-based coatings. A critical finding was that when a MoS2-based coating (on the ball) slid against DLC (on the disk), the softer MoS2 coating wore through rapidly, leading to failure. The reverse configuration (DLC ball vs. MoS2 disk) performed better, but homogenous pairs (MoS2-based vs. MoS2-based) generally showed lower and more stable friction.

Environmental storage stability is vital for space components. Coatings were subjected to liquid nitrogen immersion (-196°C) for 1 hour, followed by storage at +70°C for 1 hour. Post-storage tribological tests revealed a key differentiator: while the MOSTP coating’s friction performance remained largely unchanged, the friction of the TiN+MoS2/Zn coating at +100°C degraded significantly (μ increasing from 0.020 to 0.05). This is attributed to inter-diffusion of Zn and MoS2 layers at temperature, disrupting the beneficial superlattice structure. The MOSTP’s nanocomposite structure demonstrated superior thermal stability.

Additional parametric studies showed that a moderately higher substrate surface roughness (Ra ~1.6 μm) promoted lower friction, likely by providing better coating adhesion and debris entrapment sites. Increased sliding velocity generally increased the friction coefficient, highlighting the importance of testing under realistic strain wave gear sliding speeds.

Performance Evaluation in Actual Strain Wave Gear Reducers

Based on the fundamental screening, two coating strategies were selected for full-scale validation on commercial strain wave gear reducers (models XBS-40-100 and XBS-60-120):

- MOSTP & MOSTP: Both the flexible and circular splines coated with the MOSTP nanocomposite.

- DLC & MOSTP: Circular spline coated with DLC and flexible spline coated with MOSTP.

These were compared against baseline units lubricated with standard PFPE and MACS greases.

1. Transmission Accuracy (Backlash and Error)

Transmission accuracy, defined by positional error and lost motion (backlash), is critical for precision pointing. Measurements were taken pre-coating, post-coating, and after thermal vacuum cycling.

The results were highly encouraging. For the XBS-40-100 reducer with MOSTP on both splines, the transmission error and backlash after coating were ≤1’35” and 1’18”, respectively—virtually identical to the uncoated gear and significantly superior to the greased units (which showed errors >2’30”). The DLC&MOSTP combination also maintained excellent accuracy. This conclusively demonstrates that a well-applied solid lubricant coating does not detrimentally affect the精密 meshing geometry of the strain wave gear; in fact, it preserves it better than grease which can cause drag and settling issues.

2. Transmission Efficiency Across a Wide Temperature Range (-90°C to +100°C)

This was the most critical test. Efficiency \(\eta\) was measured as the ratio of output to input power, accounting for losses:

$$

\eta = \frac{T_{out} \cdot \omega_{out}}{T_{in} \cdot \omega_{in}} \times 100\%

$$

where \(T\) is torque and \(\omega\) is angular velocity. The reducers were tested at multiple torque levels across the temperature spectrum.

The solid-lubricated strain wave gears exhibited remarkably stable and high efficiency. The XBS-40-100 (MOSTP&MOSTP) maintained an efficiency between 69.4% and 82.8% across the entire range. The XBS-60-120 (DLC&MOSTP) performed between 66.2% and 86.7%. In stark contrast, the grease-lubricated units suffered catastrophic efficiency drops at low temperatures. PFPE grease efficiency plunged to around 30% at -90°C, while MACs grease became nearly ineffective, with efficiency around 15%. This data, summarized in Table 3, provides a decisive performance envelope.

| Reducer Model | Lubrication Strategy | Efficiency at -70°C | Efficiency at +100°C | Total Efficiency Range (-90°C to +100°C) |

|---|---|---|---|---|

| XBS-40-100 | MOSTP & MOSTP | ~74.4% | ~82.8% | 69.4% – 82.8% |

| XBS-60-120 | DLC & MOSTP | ~78.8% | ~86.7% | 66.2% – 86.7% |

| XBS-40-100 | PFPE Grease | ~32% (extrapolated) | ~82% | ~30% – 82% |

| XBS-40-100 | MACs Grease | ~15% (extrapolated) | ~81% | ~15% – 81% |

3. Thermal Vacuum Cycling Endurance

Finally, the coated reducers underwent thermal vacuum cycling (between -90°C and +100°C under vacuum < 6.65 mPa) with operational cycling under load. Both solid-lubricated units completed the test successfully without degradation in performance, confirming their robustness against the thermal stresses and vacuum conditions typical of space.

Conclusion and Implications

This comprehensive investigation, from coating material science to full-system validation, establishes a clear technical pathway for lubricating strain wave gears destined for harsh space environments. The key conclusions are:

- MoS2-based nanocomposite coatings (like MOSTP) offer an optimal balance of low friction, good wear resistance, and—most importantly—exceptional stability after exposure to extreme temperature storage. They outperform simpler superlattice coatings in terms of environmental robustness.

- Coating compatibility is crucial. Pairing a hard DLC coating with a soft MoS2-based coating can be effective if the DLC acts as the counter-face, but homogeneous MoS2-based pairs provide very consistent performance.

- Solid lubrication preserves gear accuracy. Properly applied coatings do not interfere with the精密 meshing of the strain wave gear, maintaining transmission error and backlash at levels equal to or better than the unlubricated state, and superior to grease-lubricated units.

- Solid lubrication enables wide-temperature operation. This is the most significant finding. While conventional space greases fail at cryogenic temperatures, solid lubricant coatings maintain high transmission efficiency (65-85%) across the entire -90°C to +100°C range. This dramatically expands the operational envelope for spacecraft mechanisms in deep space or planetary surface missions.

The performance data generated here provides a critical empirical basis for selecting lubrication strategies for future missions. For applications where temperature extremes, vacuum stability, and long-term reliability are paramount—such as lunar rovers, Mars landers, or deep-space probes—advanced solid lubrication coatings on strain wave gear reducers are not just an alternative but a necessary enabling technology. Future work will focus on extending the operational life assessment and optimizing coating deposition processes for complex strain wave gear geometries.