When Abaqus is used to simulate the meshing stiffness of herringbone gear, the calculation accuracy is affected by the increased calculation amount of the model considering the support structures such as hubs and shafts. In order to obtain accurate meshing stiffness, it is necessary to simplify the herringbone gear system model. The three-dimensional simplified model of herringbone gear is meshed. Because the mesh density of herringbone gear teeth and wheel hub is different, the mesh is divided respectively after the mesh is divided. The herringbone gear tooth is first divided into a tooth to generate the surface mesh of the end face. At the same time, the solid mapping division function of the software is used to generate the volume mesh of a single helical gear (as shown in Figure 1), and then the volume mesh of the entire helical gear is obtained. Considering the influence of symmetry deviation, the herringbone gear studied in this paper can be regarded as that the teeth on both sides are not completely symmetrical in the actual model, but the helical gear on one side has a small offset of the center angle with respect to the other side. Finally, it is necessary to copy and rotate the helical gear mesh to make it the target mesh, that is, generate the herringbone gear body mesh with symmetry deviation, as shown in Figure 2.

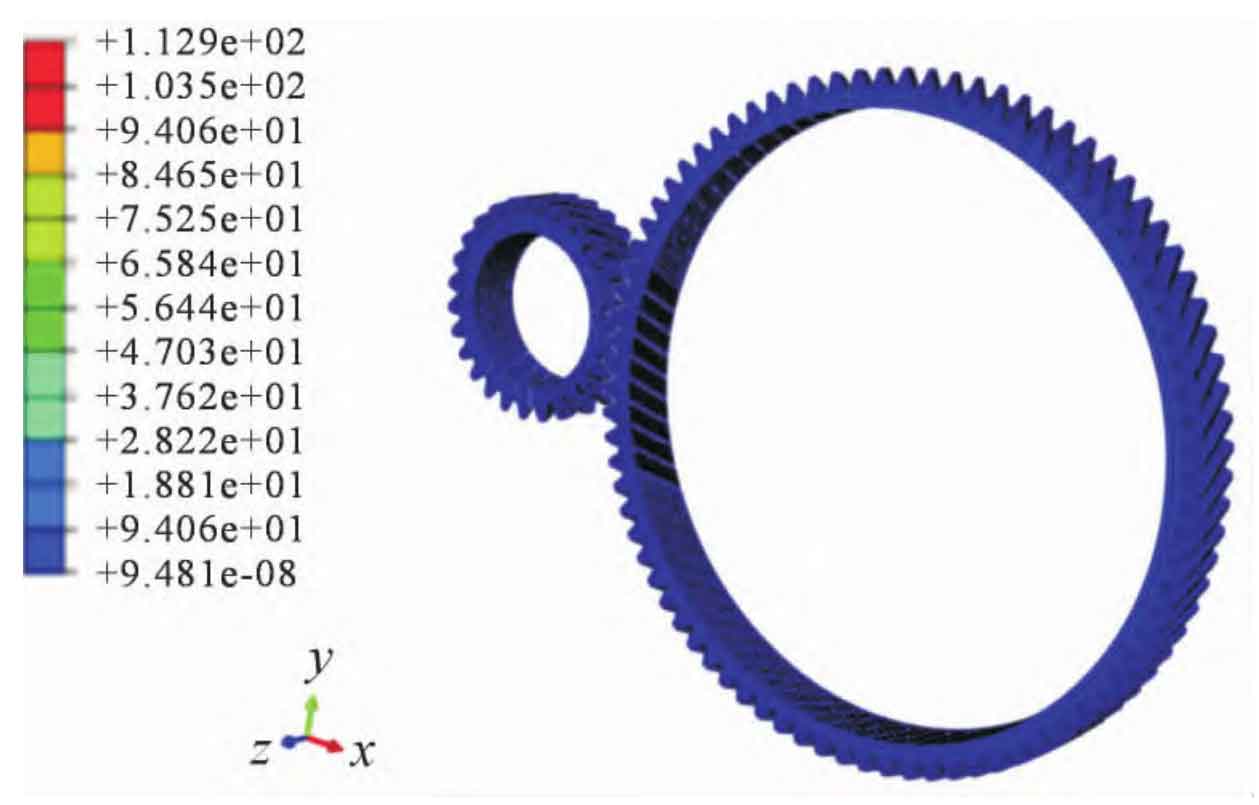

The gear model parameters used in the simulation are consistent with the herringbone gear parameters measured previously. During the simulation, all the degrees of freedom except the degree of freedom of the two gears rotating around the shaft are constrained. A low quasi-static speed is applied to the pinion, and a rated load torque is applied to the big wheel for quasi-static simulation of herringbone gear meshing transmission. Figure 3 shows the meshing state at a certain time in the gear meshing simulation. It can be seen from the meshing stiffness curve (Figure 4) obtained by Abaqus that, due to the existence of symmetry deviation, there is a deviation in the meshing stiffness curve of helical gear pairs on both sides of herringbone gear, and the meshing stiffness of the right helical gear pair is slightly less than the meshing stiffness of the left gear pair.