The reason of gear forging folding is that the metal flow is not smooth during final forging, so reducing the trend of gear forging folding should be realized by improving the metal flow in the final forging process.

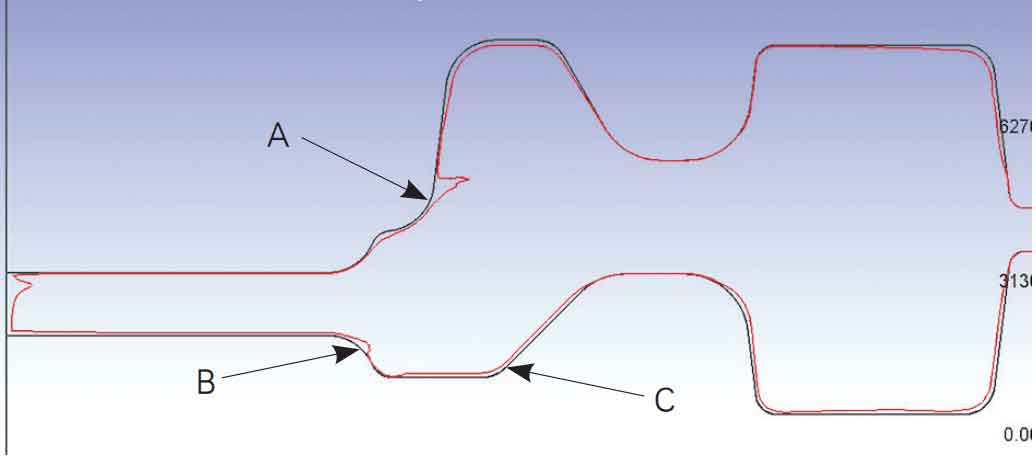

The reasons why the metal flowing out of the skin meets great resistance in the final stage of final forging are as follows: ① the flow rate of the metal flowing out of the skin is greater than that of the metal at C in Figure 1; ② The transition between the die surface at the skin connection and the die surface at C is not smooth enough, resulting in the metal around B being easily driven.

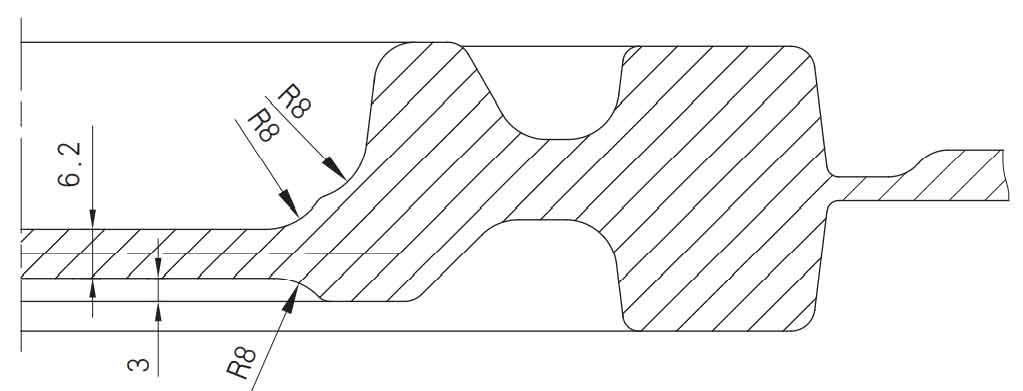

Then, it is necessary to reduce the difference of metal flow rate between the two parts and let the two die surfaces transition gently. According to these needs, modify the mold cavity, lower the lower mold at the skin connection, and increase the fillet at B (Fig. 2). This will make the metal flowing out of the skin closer to the die surface at C, and the metal flow at C will be accelerated, which is not easy to form a large resistance to the metal at the skin, and make the metal flow more smoothly at B.

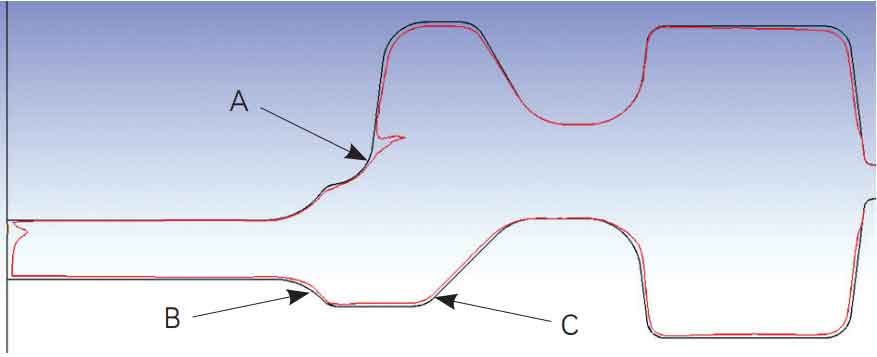

Deform 2D is used to simulate the final forging process after changing the die cavity, and the streamline 0.5mm away from the surface is filled, as shown in Fig. 3.

From the modified streamline simulation, the trend of gear forging folding has been eliminated to a great extent. In practice, when the mold is repaired according to this mold change scheme and produced again, the forging surface of the original gear forging folding does not appear gear forging folding again (Fig. 4), which confirms that the previous analysis of the causes of gear forging folding is correct and shows that the solution adopted is effective.