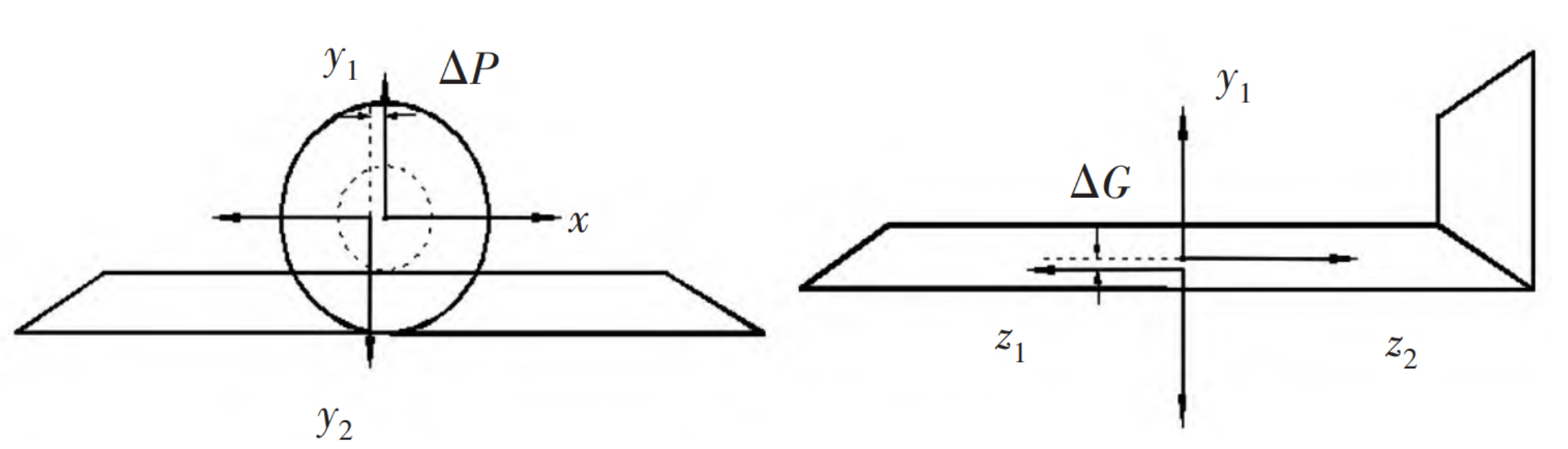

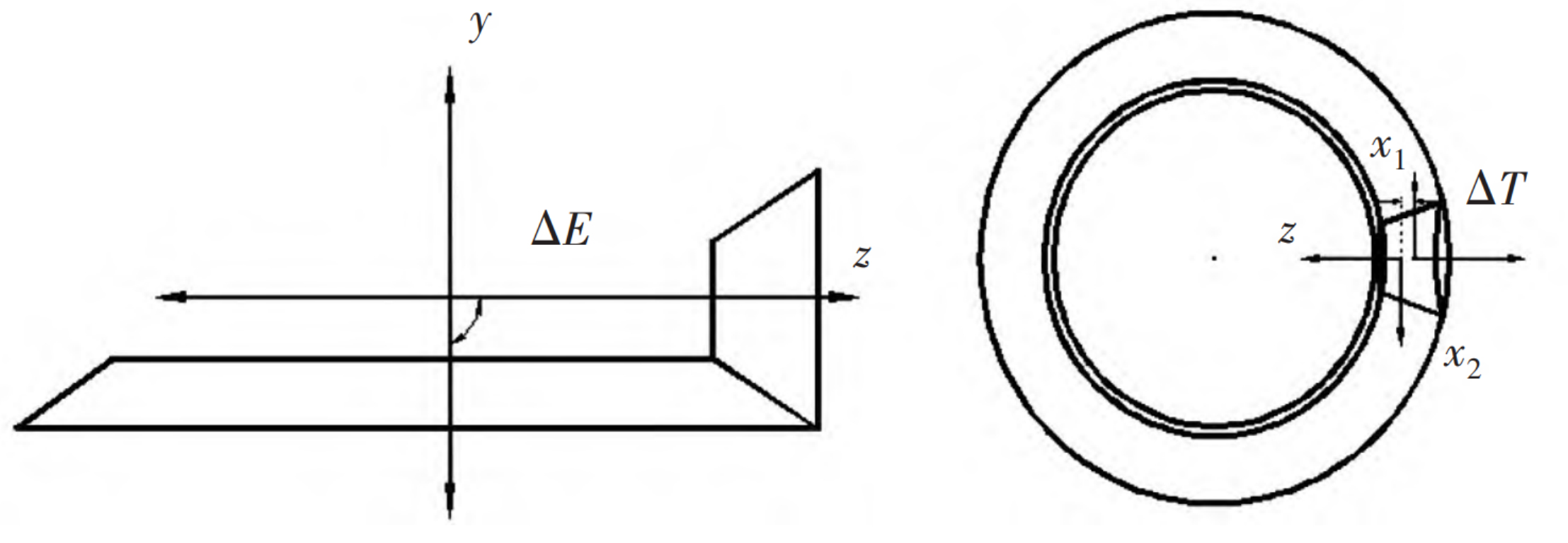

The spiral bevel gear with installation error will affect the meshing quality, vibration noise, tooth surface contact mode, etc. of the spiral bevel gear. There are four main forms of installation error, as shown in the figure.

There is axle spacing offset error Δ P. As shown in Figure (a). Axial deviation error of large gear Δ G. As shown in Figure (b). There is axis intersection offset error Δ E. As shown in Figure (c). Pinion axial error exists Δ T. As shown in Figure (d). In practical engineering, four groups of errors may occur at the same time and act on the gear comprehensively.