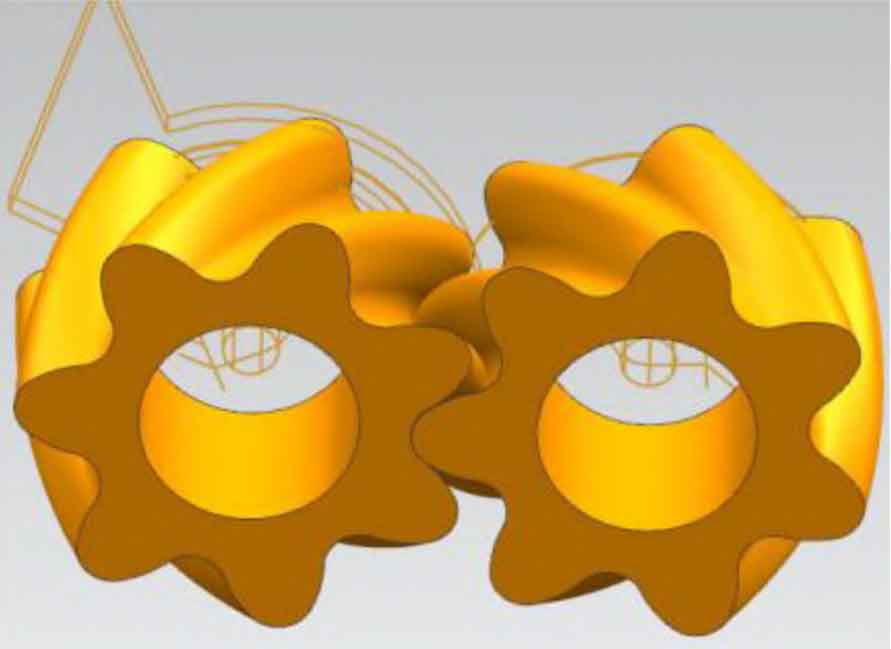

When the spiral bevel gear is running, the working conditions of each tooth are completely consistent, so it can be considered that the temperature distribution of each tooth on the gear tooth is the same, so the single tooth model of spiral bevel gear is used for simulation analysis.

The body temperature of spiral bevel gear teeth is calculated by Steady-State Thermal module in ANSYS. First, the meshing node is loaded with average heat generation, and then the convection heat transfer coefficient is loaded on each surface of the single-tooth model, and the body temperature at the meshing node is obtained by solving.

The transient temperature of spiral bevel gear teeth is calculated by the Transient Thermal module in ANSYS. Take the body temperature as the initial condition, load the instantaneous heat generation at the meshing node, set the step length as one meshing period, load the same convective heat transfer coefficient, and calculate the instantaneous temperature at the meshing node.

The flash temperature is calculated by calculating the difference between the instantaneous temperature and the body temperature.