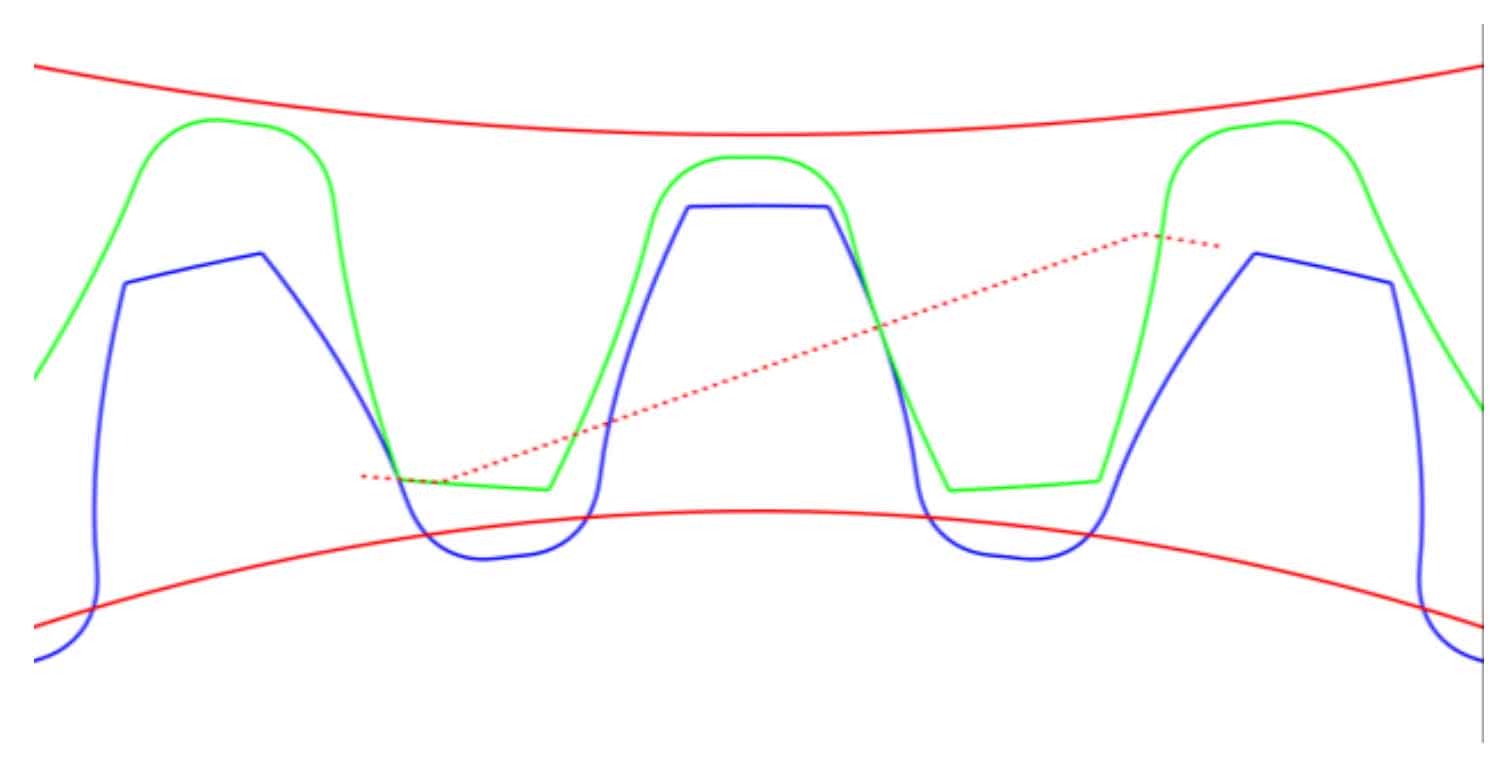

Ideally, the meshing form of spur gear pair is shown in Figure 1. It can be seen that one end of the gear teeth is “perfectly engaged”, and the other end has a certain gap due to the existence of backlash. However, due to errors, time-varying meshing stiffness and other factors, the actual spur gear pair will inevitably cause meshing impact between gear teeth. Therefore, in a sense, the meshing impact excitation is the result of stiffness excitation and error excitation, and the meshing impact excitation is similar to the error excitation, which is caused by the deviation between the theoretical meshing trajectory and the actual meshing trajectory. But compared with error excitation, meshing impact belongs to force excitation, while the former is displacement excitation. Therefore, the meshing impact excitation can be restrained by simultaneously reducing the transmission error and changing the meshing stiffness. In addition, since the time-varying meshing force and meshing impact excitation are both force excitation, and the latter is the result of the former, it is considered that the meshing impact excitation can also be weakened by reducing the time-varying meshing force.

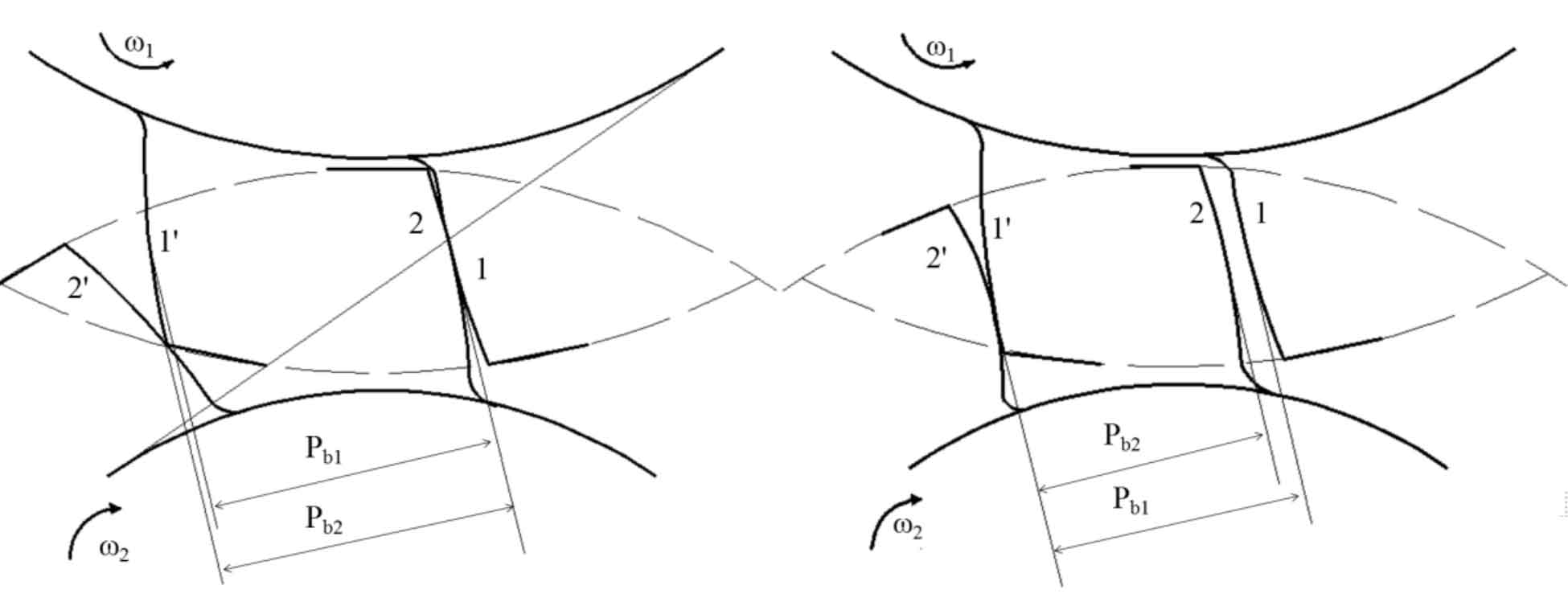

(a) Inner meshing impact (b) Outer meshing impact

Figure 2 is a schematic diagram of spur gear meshing impact excitation, in which Pb1 and Pb2 represent the actual base pitch length of driving wheel and driven wheel respectively. Under ideal meshing conditions, the base joints of the driving and driven wheels should be completely equal, but under the excitation of meshing impact, the length of the base joints of the driving and driven wheels will have some errors. When Pb1Pb2, the actual base joint of the driving gear is large, and the actual transmission ratio of the spur gear is slightly higher than the ideal transmission ratio. The tooth top of the driving gear will hit the tooth root of the driven gear, causing “meshing impact”. Because the meshing impact excitation will make the theoretical meshing line of the spur gear pair offset and affect the actual speed of the driving and driven wheels, the spur gear pair will often produce severe vibration and noise.