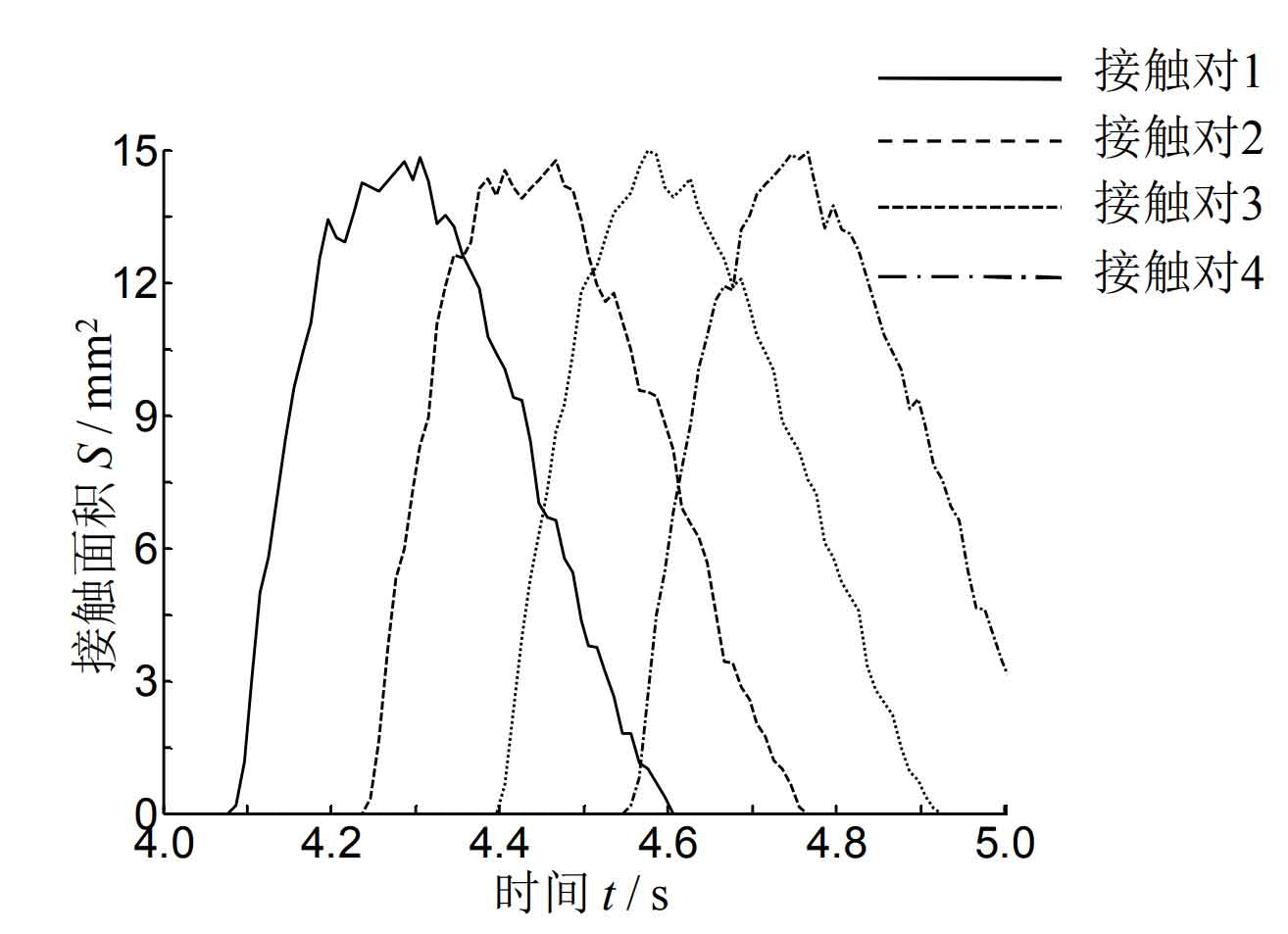

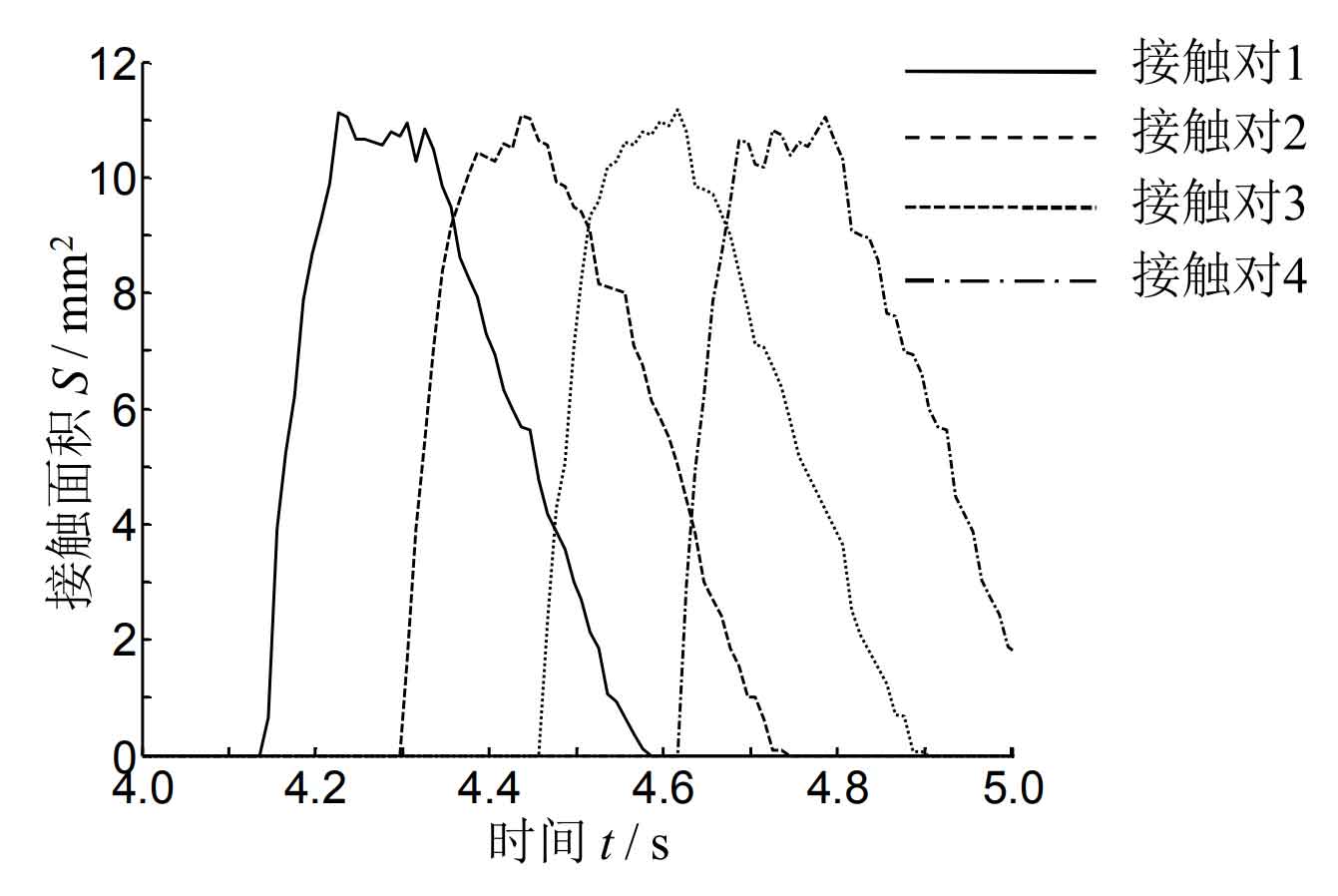

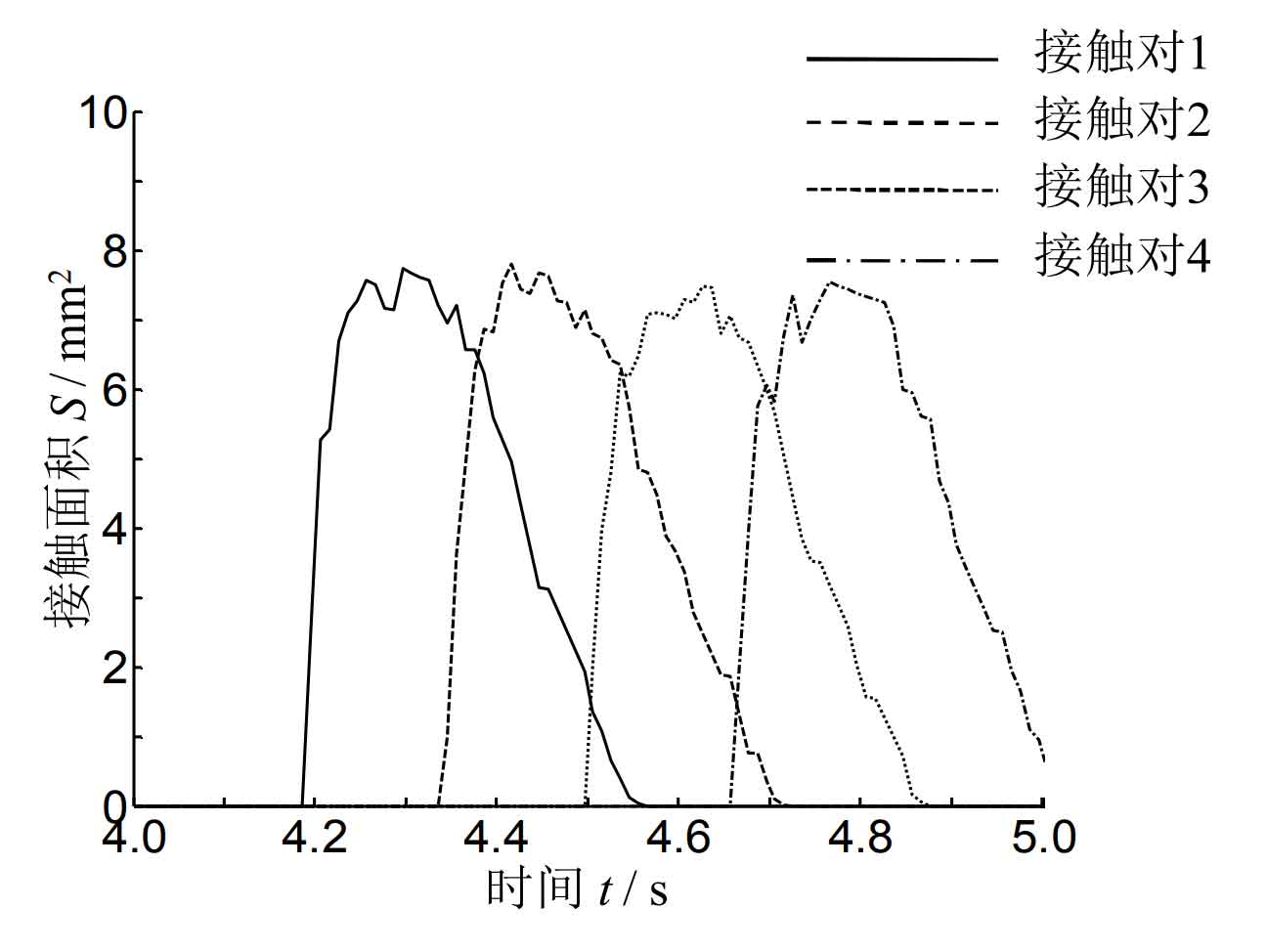

The size and position of the tooth surface contact area of spiral bevel gear affect the vibration, noise and bearing capacity of transmission. In order to explore the change law of contact area under different working conditions in detail, the change lines of contact area in the results are extracted respectively, as shown in Figure 1-3.

It can be seen from the time-varying curve of the contact area under static loading that the change law of the contact area of spiral bevel gear in the process of meshing transmission is basically the same under various working conditions; At the initial stage of meshing, the contact area is small; With the increase of meshing time, the contact area increases and tends to be stable; The size of the contact area is directly related to the size of the load. With the increase of the load, the contact area gradually increases.