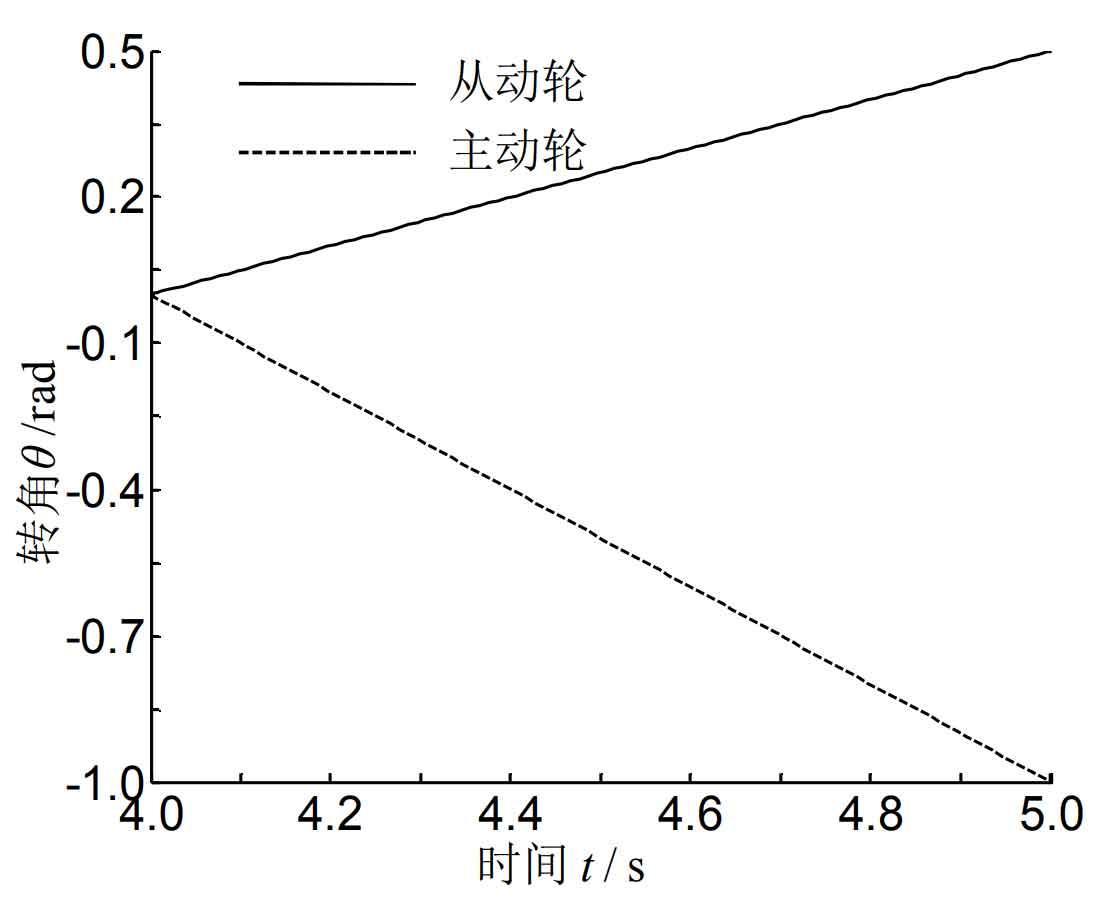

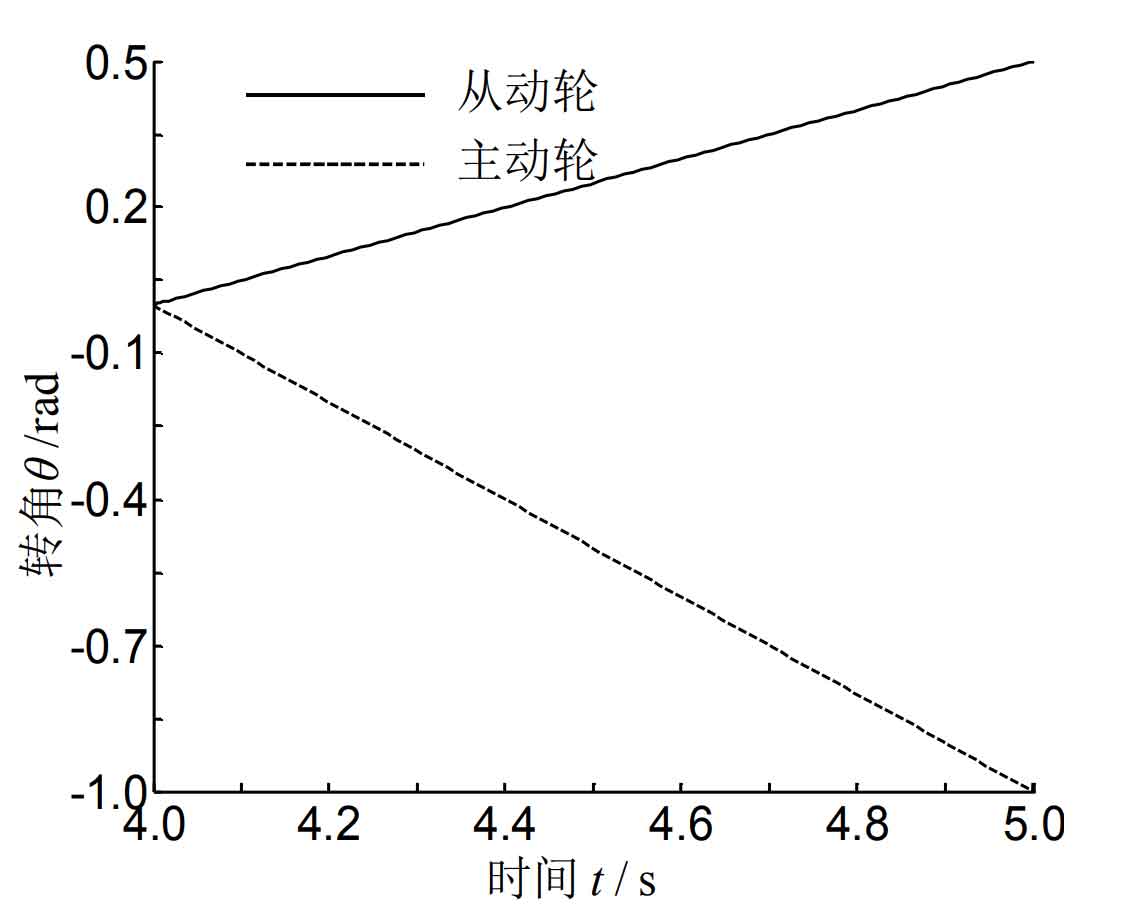

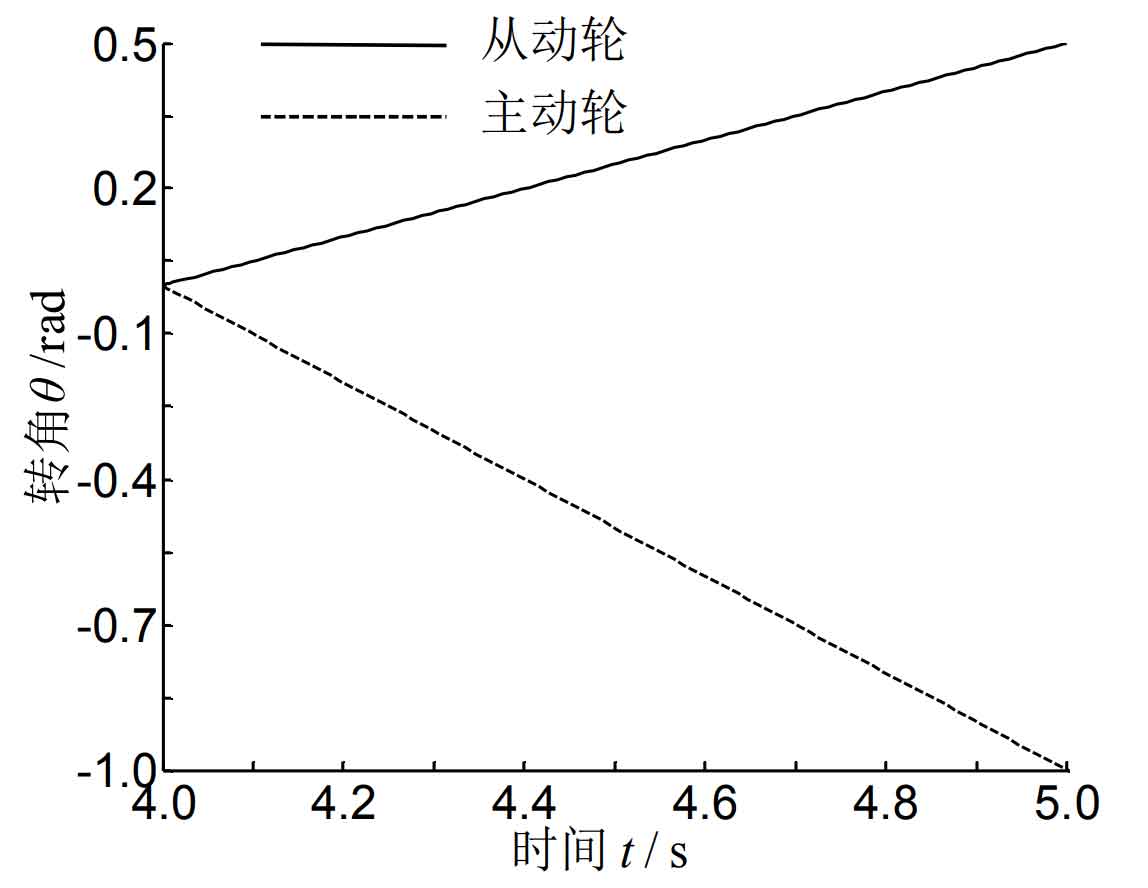

After the calculation, in order to obtain the meshing transmission accuracy of spiral bevel gear, in the ABAQUS post-processing module, the change law of rotation angle in the meshing transmission process of spiral bevel gear under various working conditions is extracted respectively, as shown in Figure 1 ~ 3.

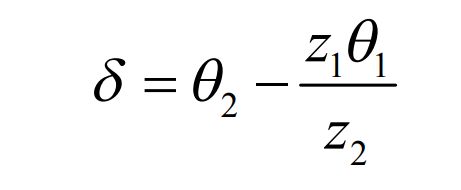

It can be found from the angle change curve under various working conditions in Figure 1 ~ 3 that the angle change law under different load conditions is basically the same without obvious difference. In order to better analyze the influence of load on spiral bevel gear transmission, the concept of transmission error is introduced to further analyze the transmission characteristics of spiral bevel gear. The transmission error curve of spiral bevel gear can better reflect its meshing transmission performance, such as tooth surface contact quality, transmission accuracy, vibration and noise. Define static transmission error δ For the deviation value between the actual rotation angle of the spiral bevel gear big wheel and the theoretical value when the spiral bevel gear small wheel rotates a certain angle, the expression of transmission error can be expressed as:

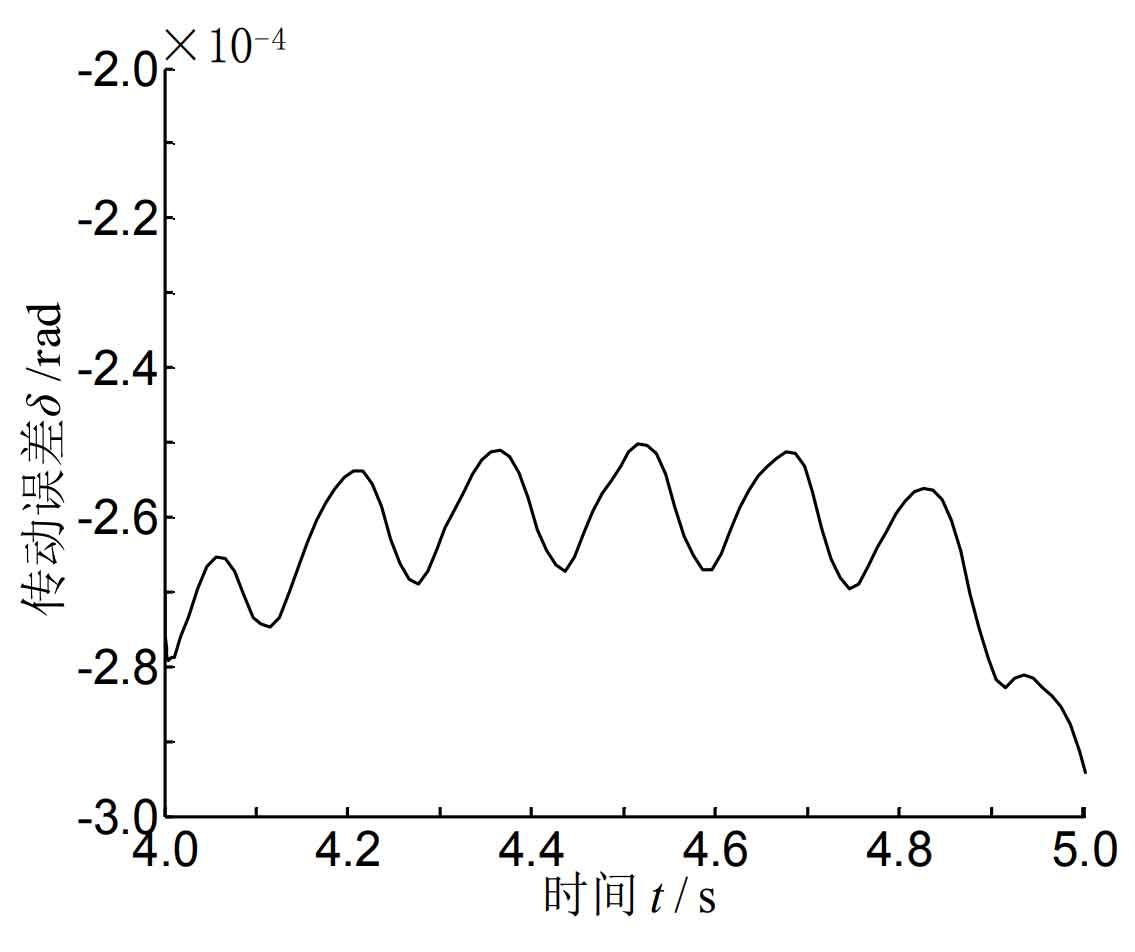

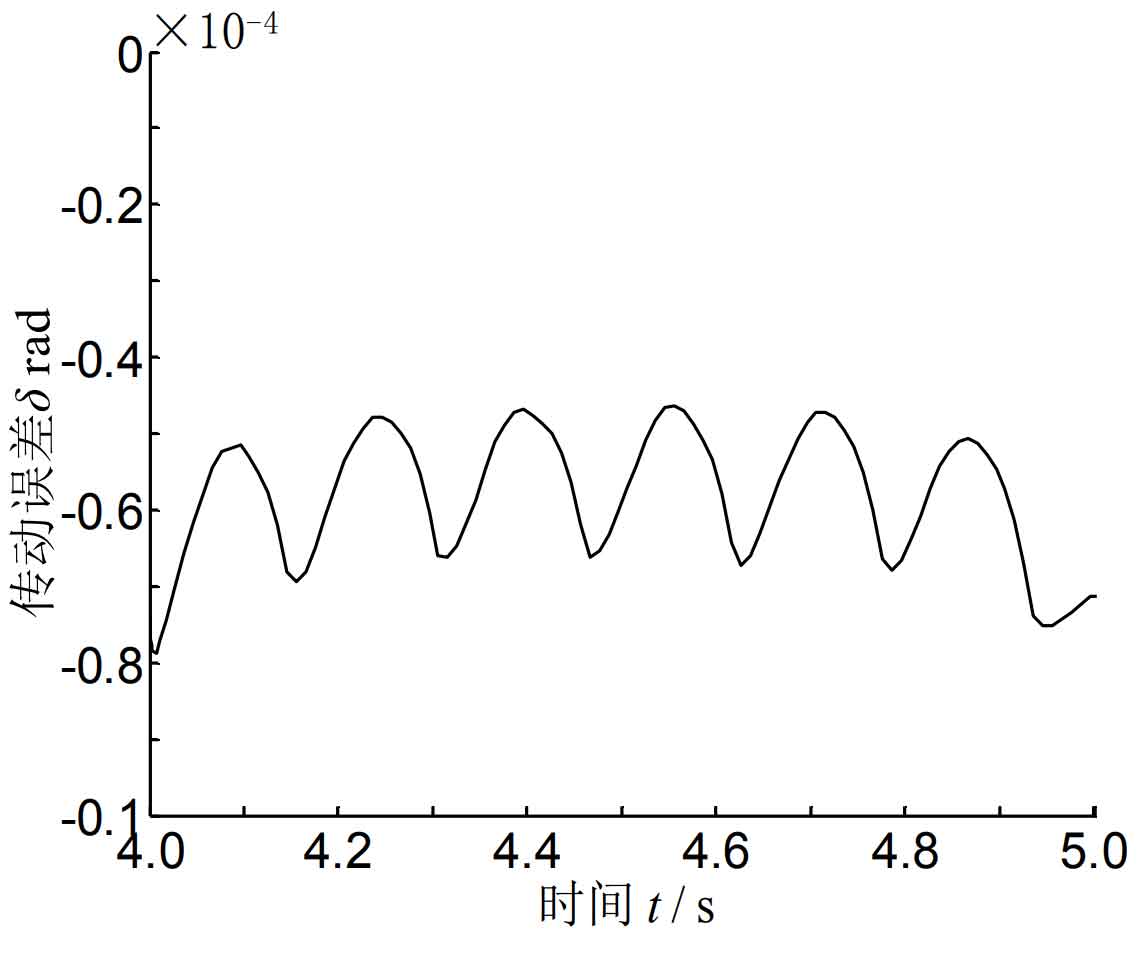

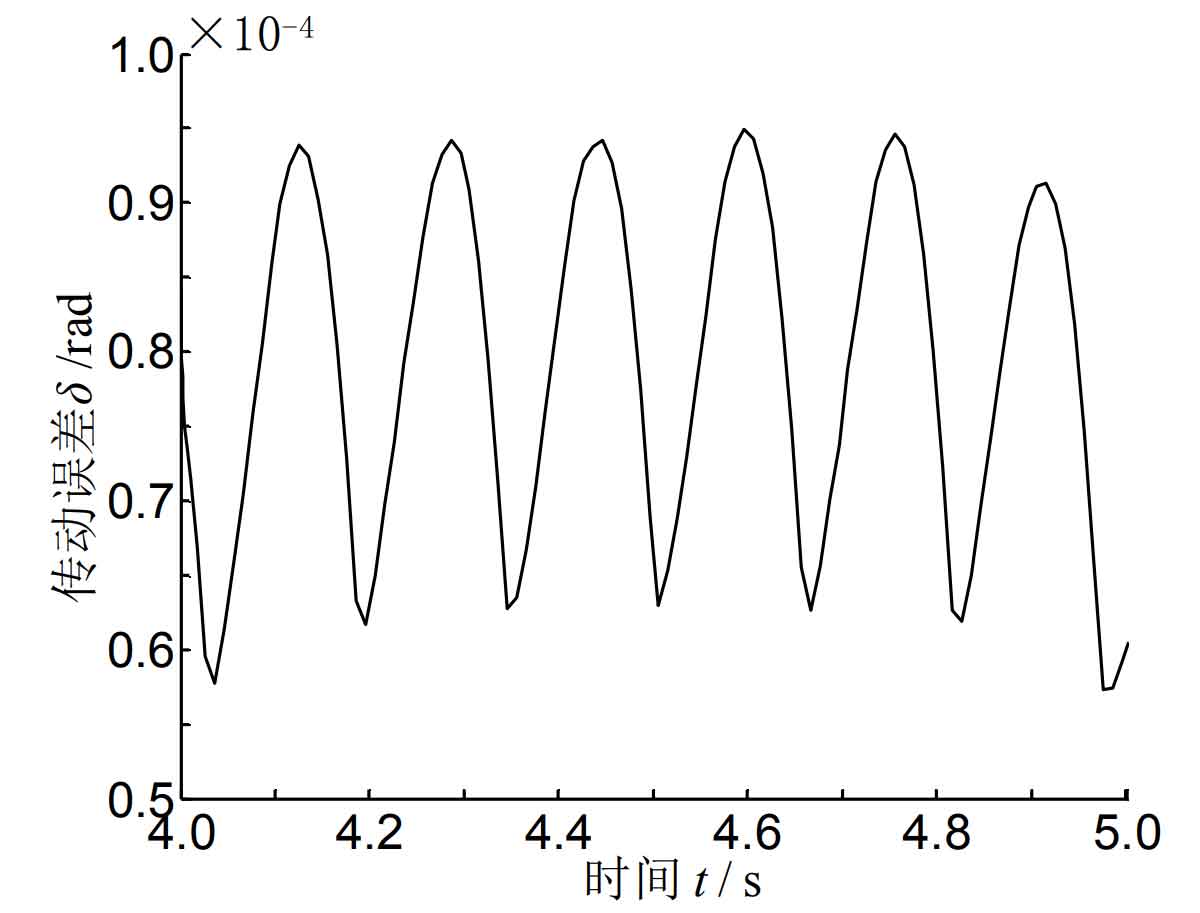

In the formula, θ 1 、 θ 2 is the actual rotation angle of the main driven wheel per unit time, and Z1 and Z2 are the number of teeth of large and small wheels respectively. In order to better analyze the transmission performance in the static analysis, the transmission errors under various static conditions can be obtained according to the actual rotation angle change law obtained by the finite element static analysis, as shown in Figure 4 ~ 6 respectively.

According to the transmission error curve in Figure 4 ~ 6, the order of magnitude of transmission error under each working condition under static loading is 10-4. The transmission error is small. On the one hand, it can demonstrate the correctness of the model, on the other hand, it reflects that the spiral bevel gear has high transmission accuracy. With the increase of load, the transmission error gradually changes from positive value to negative value, and the fluctuation amplitude of error curve decreases. The reduction of fluctuation amplitude of transmission error curve shows that the spiral bevel gear transmission under high load condition is more stable and the noise is reduced.