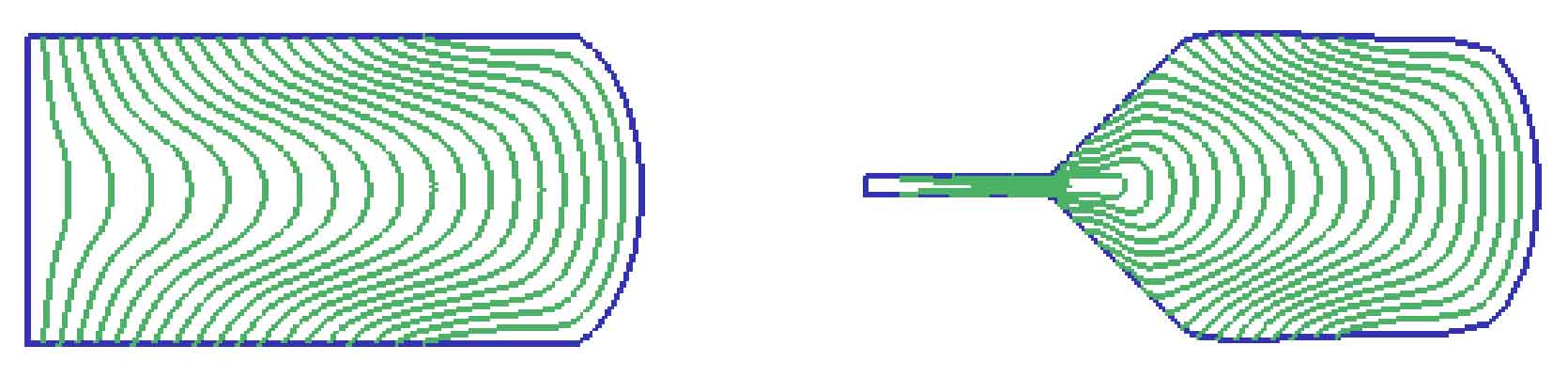

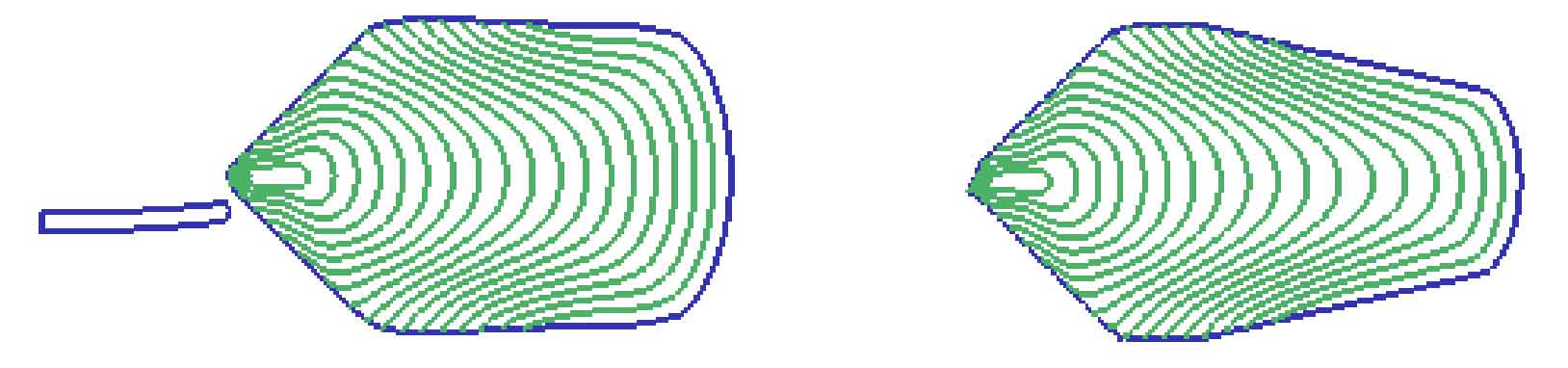

The distribution of metal streamline in each step of the blank making process of cylindrical gear ring is shown in the figure. Figure (a) shows the distribution of metal flow lines when the upsetting process is completed. After upsetting, most of the metal flow lines are exposed. These flow lines are perpendicular to the outer surface of the blank, which is unfavorable to the performance of the formed product. Figures (b) – (d) respectively show the distribution of metal flow lines at the completion of pre punching, punching and shaping steps. It can be seen from the figure that with the blank making process of cylindrical gear ring, few metal flow lines are exposed, and most of the flow lines are parallel to the outer surface of the product. This also shows that the die design in the blank making process of cylindrical gear ring is reasonable, which provides a better ring blank with streamline distribution for the rolling of cylindrical gear ring.

After the blank making process of cylindrical gear ring is completed, enter the forming module of pretreatment, select the last step of blank making process simulation calculation, and export and save the geometry obtained by blank making of cylindrical gear ring in the form of geo or IGS file.

Ring rolling (also known as ring rolling, ring rolling, reaming and ring rolling) makes the cylindrical gear ring produce continuous local plastic deformation with the help of the rolling pass of the ring rolling machine (also known as ring rolling machine, ring rolling mill and reaming machine), so as to reduce the wall thickness of the cylindrical gear ring, increase the outer diameter and form the ring section. The stress-strain and deformation flow during rolling and reaming are the same as that of mandrel reaming. The utility model is characterized in that the tool is rotating and the deformation is continuous, that is, the rolling of annular blank. When rolling and reaming, the reduction is generally small, so it has the characteristics of surface deformation.