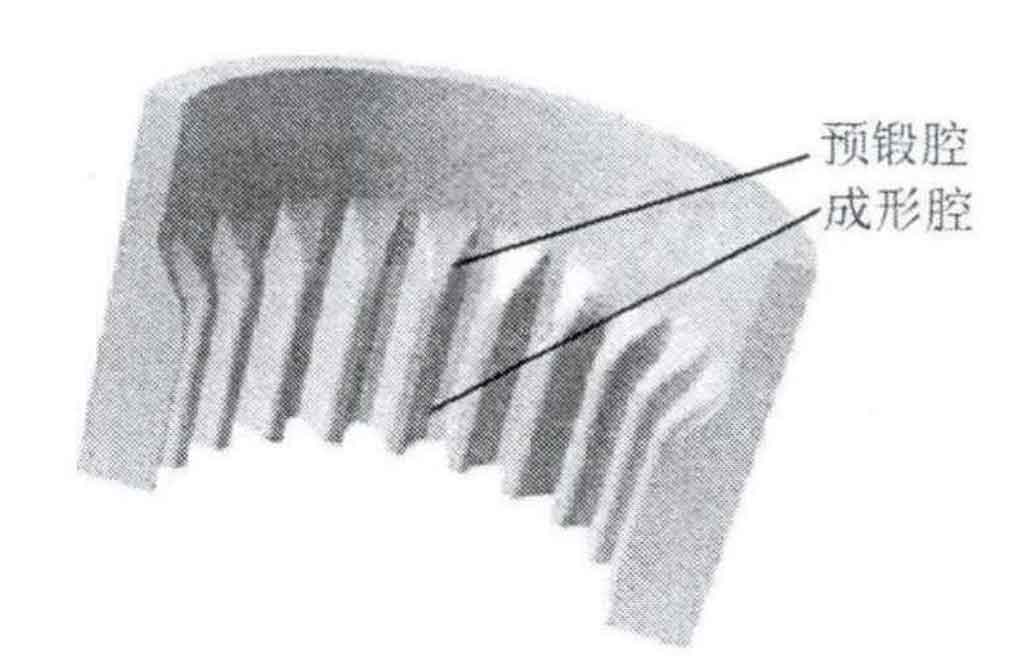

Professor Liu Quankun of Hefei University of technology proposed to simulate the continuous extrusion forming of spur gear through the streamlined concave model cavity based on modeling, which can well improve the filling of the corner of spur gear and improve the uniformity of deformation. Meng Guanjun, Qu Xinhuai, etc. According to the flow curve and the theory of equal cross-sectional area change, the mathematical model of the extrusion cavity of streamlined spur gear in line with the rheological characteristics of metal is established, and the simulation processing of the extrusion cavity of streamlined spur gear is completed by using graphic interactive automatic programming. The figure is the three-dimensional modeling diagram of streamlined four model cavity, including two parts, one is the pre forged tooth cavity, the other is the complete tooth cavity.

The figure shows the extrusion process of spur gear in streamlined concave model cavity. It can be seen from the figure that during extrusion, the wool is preformed in the pre forging forming cavity to make the semi-finished gear, and then the semi-finished spur gear is upsetted and extruded in the complete tooth cavity, so as to fill the whole die cavity with metal.

In addition, a streamlined extrusion die for computer-aided design and manufacturing is proposed, which can greatly reduce the extrusion dead zone and workload. The streamline extrusion die based on curve is studied, which can greatly reduce the extrusion force and thus reduce the die wear.