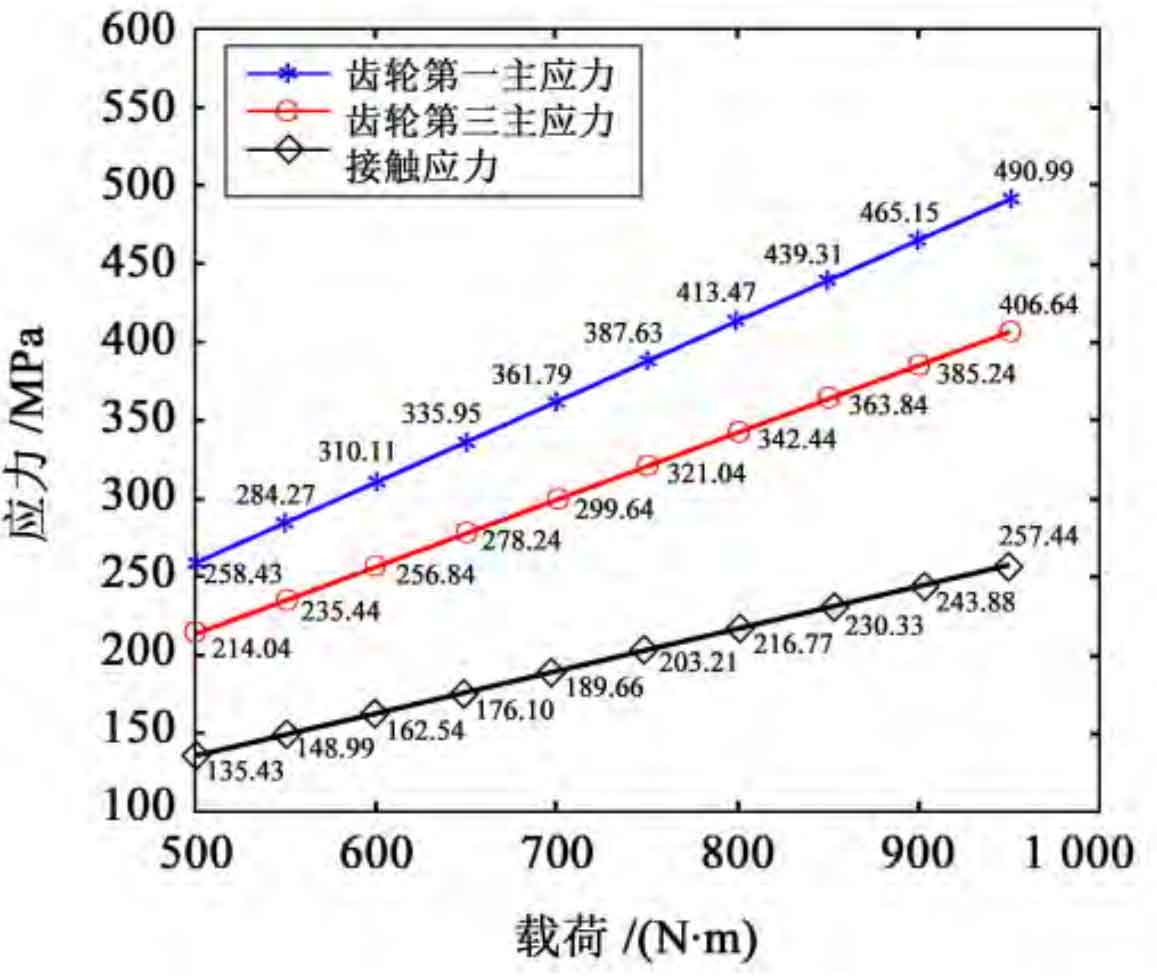

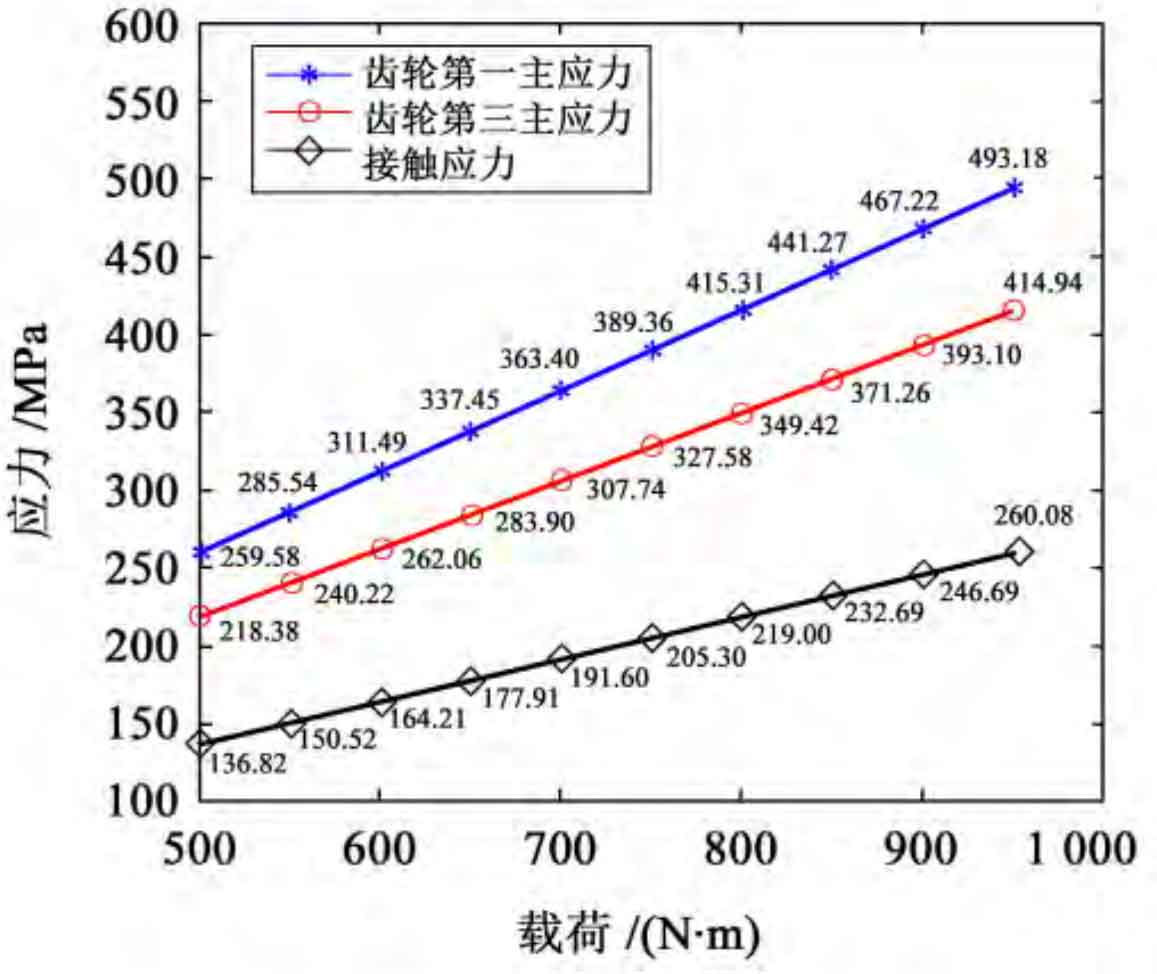

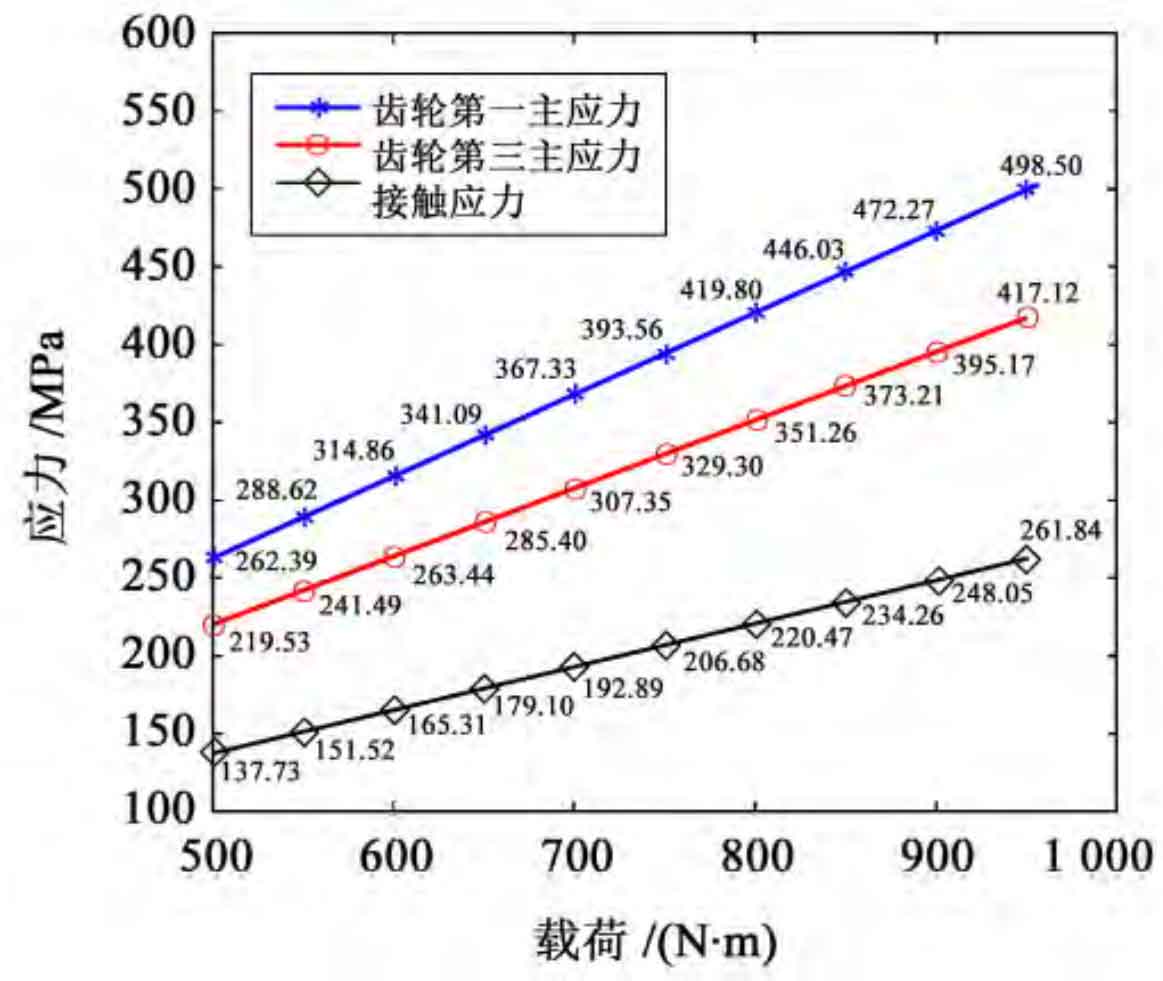

The stress analysis of hypoid gear with super reduction ratio is carried out through the finite element software Ansys Workbench. While ensuring the safety and reasonable design of the gear, without changing other conditions, set the initial reverse torque to 500 N · m and increase it by 50 N · m in turn, respectively analyze the stress of hypoid gears with different super reduction ratios at the root fillets, and obtain the first principal stress, the third principal stress and contact stress of the gear as shown in the figure.

It can be seen from Figure 20 that with the change of torque, the three stresses of hypoid gears with super reduction ratio of different root fillets increase with the increase of torque, and under the same torque, the first principal stress of the gear is greater than the third principal stress of the gear is greater than the contact stress.

By comparing Fig. (a), Fig. (b) and Fig. (c), it can be seen that when the tooth root is machined with different tip fillets, the total stress value of the super reduction ratio hypoid gear decreases with the increase of the radius of the tip fillets. It can be inferred that the tooth root fillets increase continuously in the appropriate area, which can reduce the stress concentration between the tooth roots, thus improving the strength of the hypoid gear.