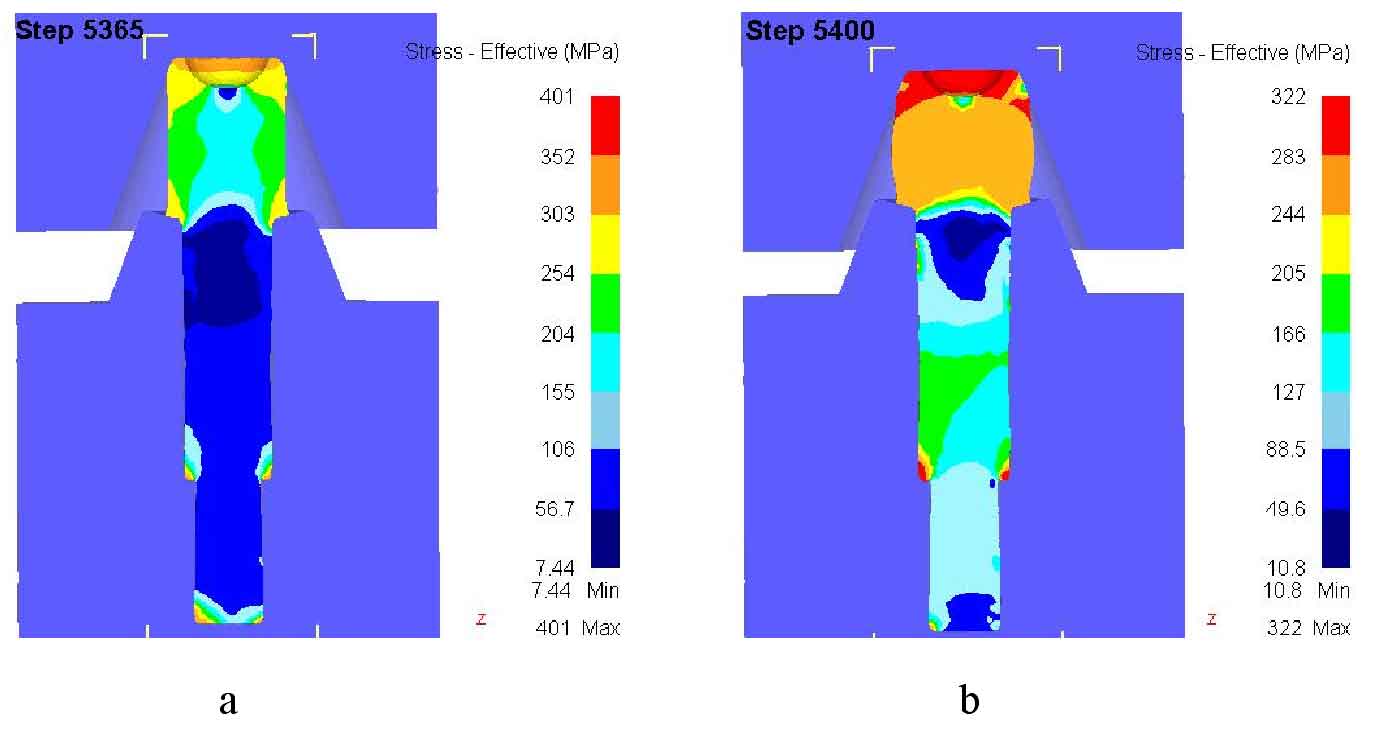

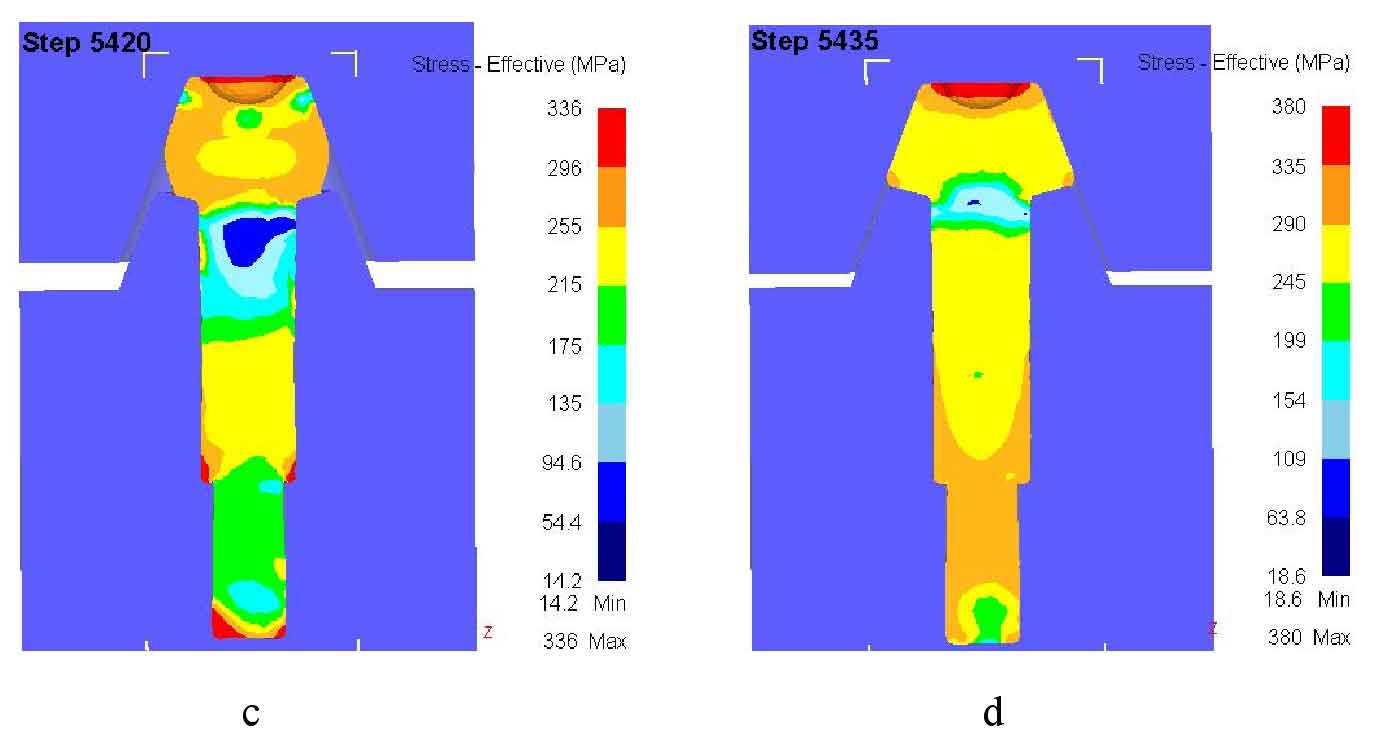

(1) Stress analysis of vertical forging process

It can be seen from Figure 1 that the stress at the conical head to be formed in the upsetting stage of the workpiece (figures a and b) is large, while the stress at the shaft part is large only at the contact position with the fillet of the lower die cavity, and the stress at the shaft part is below 200mp. After upsetting, the maximum stress is distributed in the area where the workpiece contacts the inner surface of the upper die, and the maximum value is 322mp.

The minimum value is at the neck of the forging, that is, in the central area of the shaft slightly below the parting surface. The minimum value is 10.8mp. It can be seen from the stress field of the whole forging process that this is always the area with the minimum stress. When the cone head starts forming (Fig. C and D), with the increase of metal deformation resistance, the larger stress value above has been transferred to the lower shaft. In step 5420 (Fig. C), due to the influence of the lower die on the workpiece finishing, the stress at the contact position between the workpiece and the concave fillet of the lower die is larger.

In the pit filling stage (Figure d), the larger stress value is distributed in the local area of the pit, and the maximum value is 394mp. In addition to this area, the overall stress value distribution of the workpiece is relatively uniform, and the stress value near the parting surface is slightly smaller. At the end of vertical forging (Figure E), the stress value of the upper part of the workpiece is slightly smaller than that of the lower part, but the stress distribution of the whole workpiece tends to be uniform, and the overall stress changes little, ranging from 230 to 320MP.

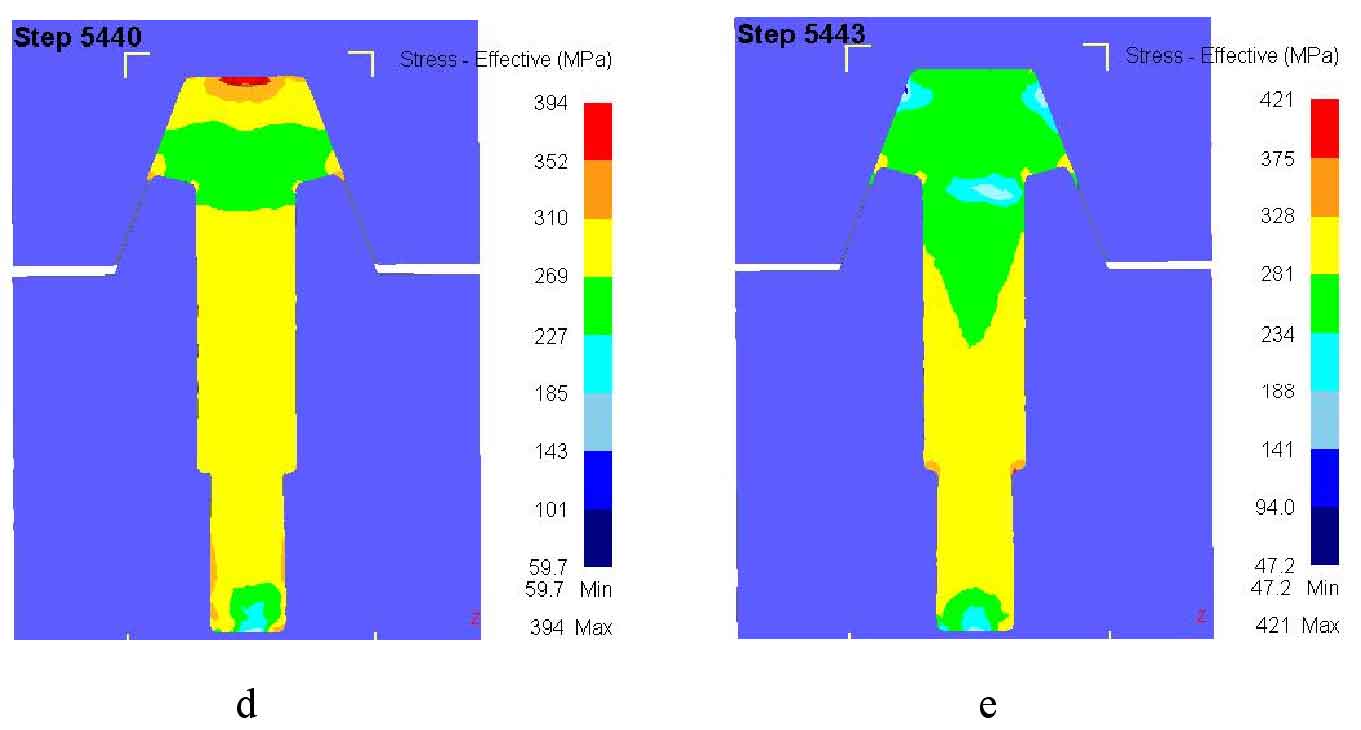

(2) Analysis of forging temperature, equivalent strain and damage at the end of forging

Fig. 2a is the temperature distribution diagram of the forging after forging. It can be seen that the temperature of the small shaft of the forging decreases rapidly due to the long contact time with the lower die. The minimum temperature of the small shaft after forging is 731 ℃. Because the small shaft has been formed, the deformation of the finished shaft is small, and it can be easily realized at 750 ℃. The overall temperature of the upper part of the forging is above 800 ℃. According to the forging temperature range of common metal materials listed by Yao zekun in forging technology and die design, this temperature meets the hot forging requirements of the cone head. The vertical forging of cone head belongs to final forging. If the final forging temperature is too high, it will cause the secondary recrystallization of grains in the forging and produce coarse grains, which is not conducive to the improvement of the final fatigue strength of the workpiece. If the final forging temperature is too low, work hardening will occur in the forging process, which will reduce the plasticity of the forging and sharply increase the deformation resistance, even cause the cracking of the forging in the forging process, or produce large residual stress in the forging. The final forging temperature of forgings is generally 50 ~ 100 ℃ higher than the recrystallization temperature. The recrystallization temperature of carbon steel is 600 ~ 650 ℃. Therefore, it is reasonable that the final temperature of the forging is between 800 ~ 928 ℃.

Figure B shows the strain gradually accumulated by the blank in the whole forming process. It can be seen from the figure that the deformation of cross wedge rolling process is the largest from blanking to final forming. In particular, the small shaft part of wedge II rolling belongs to the area with the largest deformation. Compared with cross wedge rolling, the deformation of vertical forging process is still relatively small, about 1 / 10 of that of cross wedge rolling. In the whole forming process, the maximum equivalent strain is 25.9 and the minimum is 2.69.

Figure C shows the damage value distribution of the workpiece after forming. It can be seen that there is no large damage in the process of vertical forging. The conical head obtained by vertical forging is the position with the lowest damage value of the whole workpiece, which is about 0.5. The shaft formed by cross wedge rolling is the area with large damage value, especially the small shaft formed by secondary wedge, and the maximum damage value is 3. This is because the rolling wedge rubs the workpiece repeatedly, resulting in a large damage value.

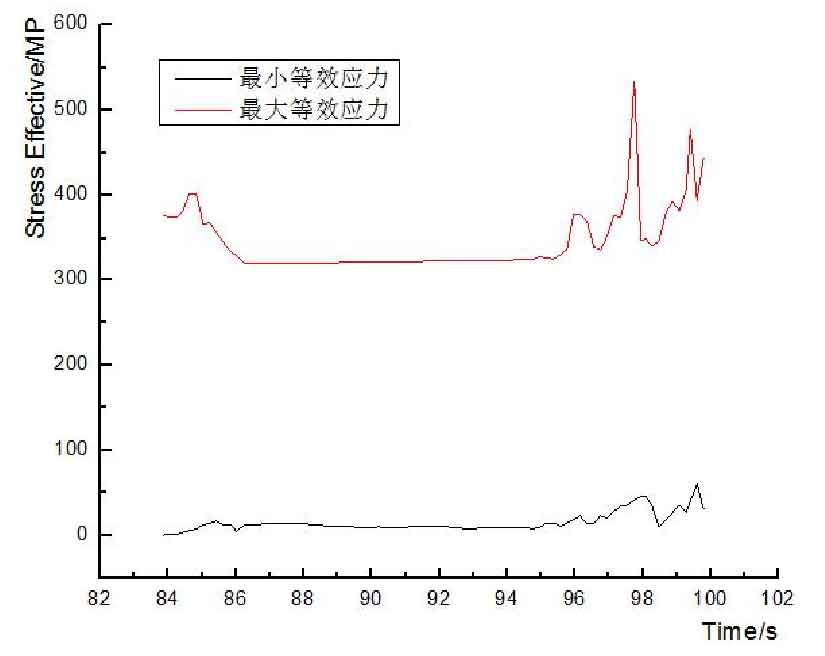

It can be seen from the curve in Figure 3 that the equivalent stress is relatively stable in the early and middle stages of cone head forming, especially in the middle stage, the maximum stress value remains almost unchanged, while the equivalent stress fluctuates greatly in the later stage. Compared with the forming process, it can be found that the relatively stable stage in the early and middle stage is the upsetting and forming stage of the workpiece, and the fluctuation of the equivalent stress value in the later stage is due to the fact that the cone shape has been basically formed and begins to fill the pit and produce flash. This process requires large stress to be realized, and flash constantly occurs while filling the pit, and the two provide conditions for each other, This leads to a large fluctuation of the equivalent stress value of the forging in the final pit filling stage.

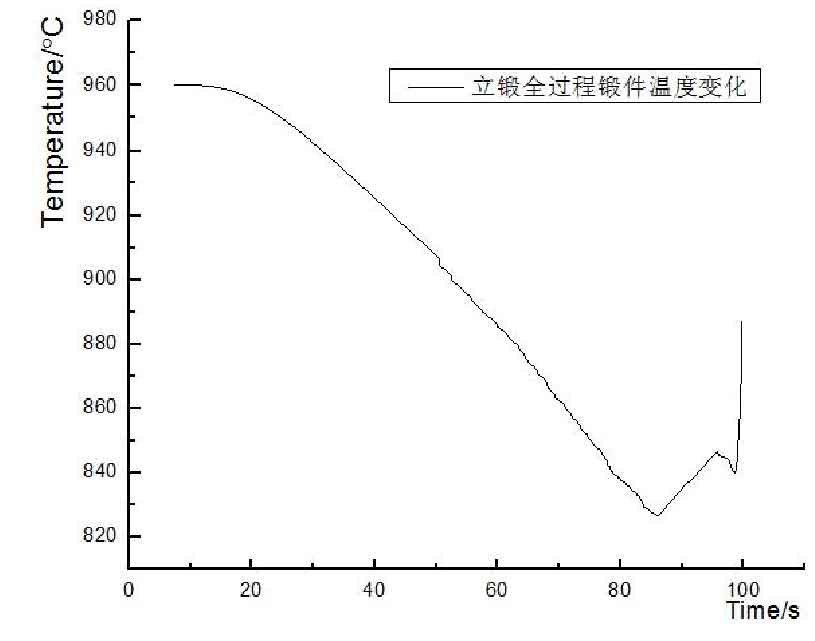

Fig. 4 shows the temperature change curve of the workpiece during the period from the end of cross wedge rolling process to the end of vertical forging. It can be seen that under the influence of heat transfer with the environment and die, the workpiece temperature decreases rapidly, and the forging temperature rises at the initial stage of cone forming, because the sum of the heat energy converted from friction heating and forging energy into the workpiece is greater than the heat lost by the workpiece. In the last stage, the temperature rises sharply due to the influence of flash.