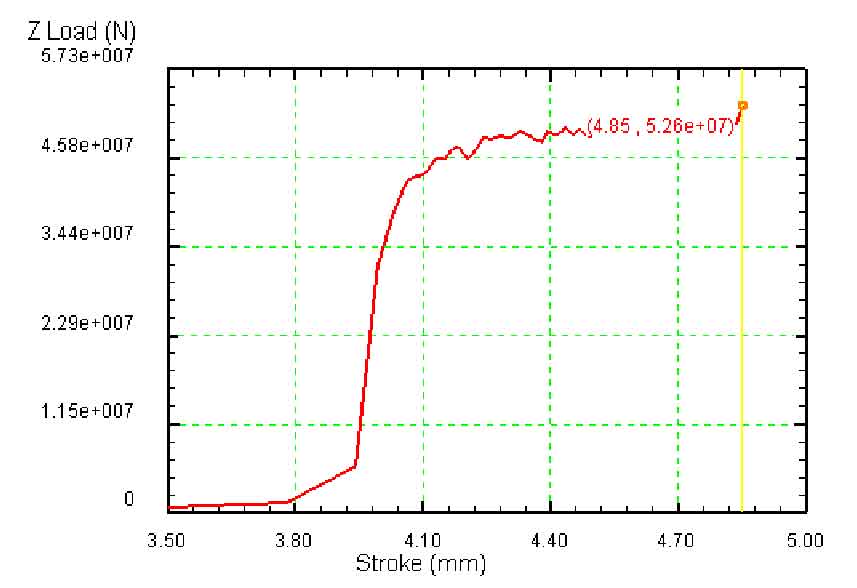

The figure shows the stroke load curve of the helical gear cold finishing process. It can be seen from the figure that after the upper die starts running, the load is very small in the initial stage. When the stroke reaches 4 mm, the load suddenly increases and finally fluctuates in a very small range.

After the upper die starts to move, at this time, there is a dimensional difference between the helical gear warm forging and the tooth cavity of the upper die, so there is still a gap in the tooth cavity. Therefore, the deformation is mainly the deformation of the tooth shape. With the downward movement of the upper die, the tooth shape diffuses evenly, the height of the tooth shape becomes lower and the width becomes wider, gradually filling the whole tooth cavity, resulting in a sharp increase in the load.

Then flash occurs under huge compressive stress, and the load floats in a certain range. The maximum load of helical gear cold finishing process can reach 52600 kn, which is about 3.3 times of the maximum load of warm precision forging process. This is because the processing temperature of helical gear cold finishing process is low and the plasticity of metal is relatively low, resulting in large deformation resistance and load of material.