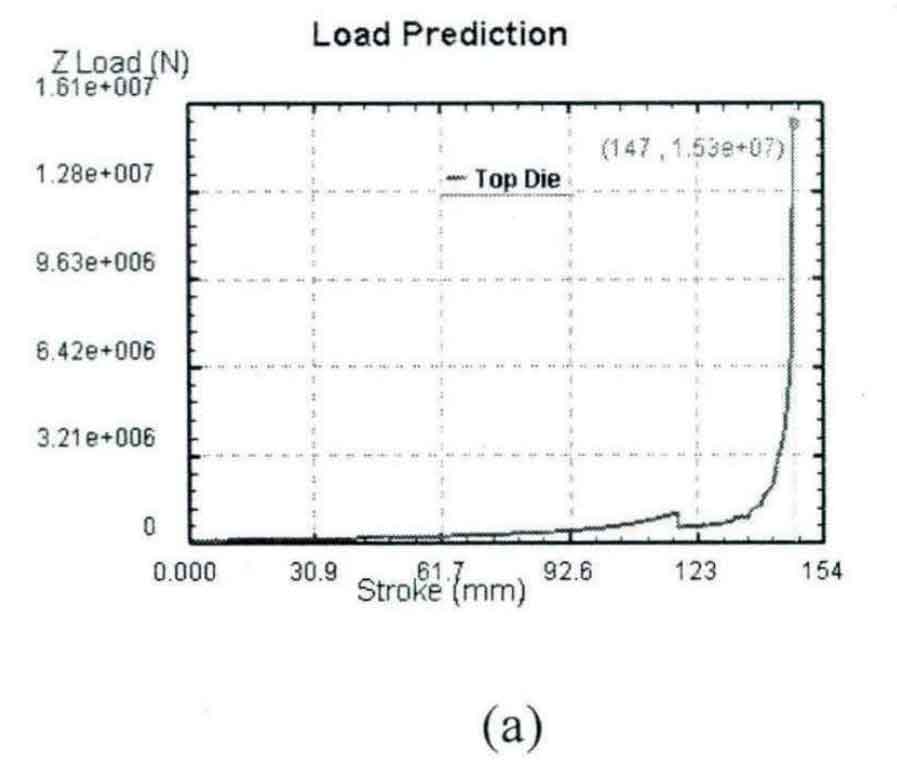

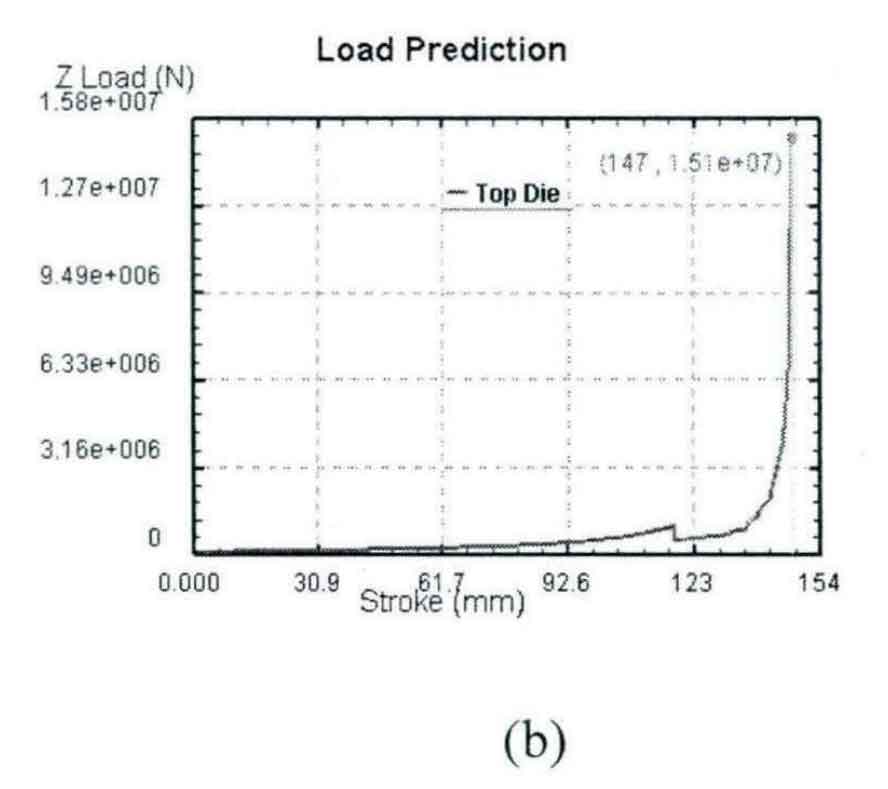

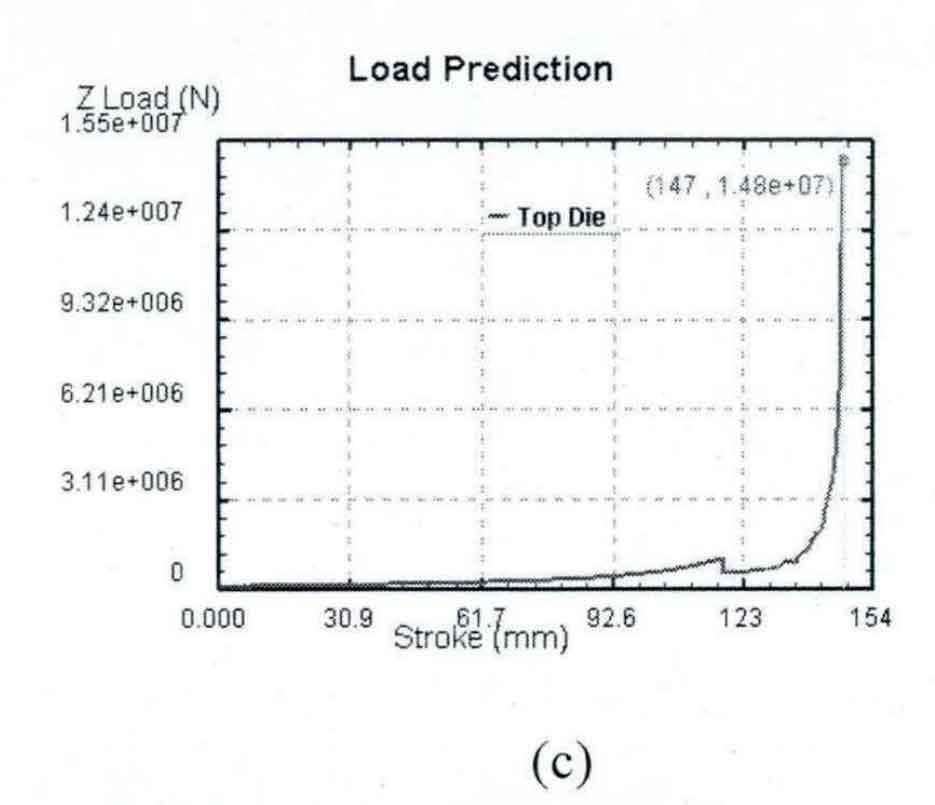

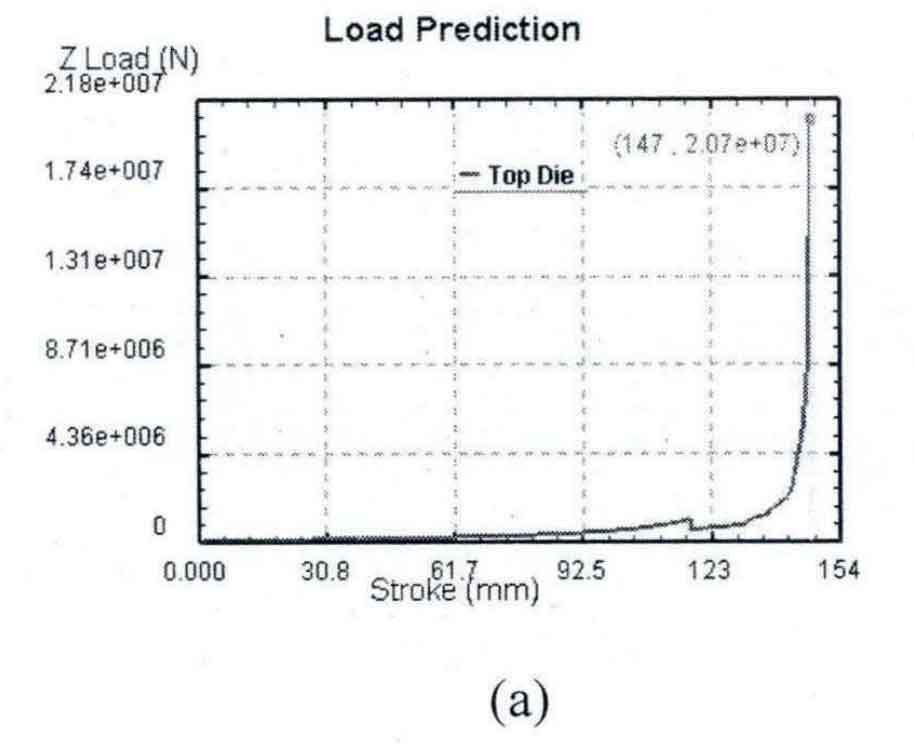

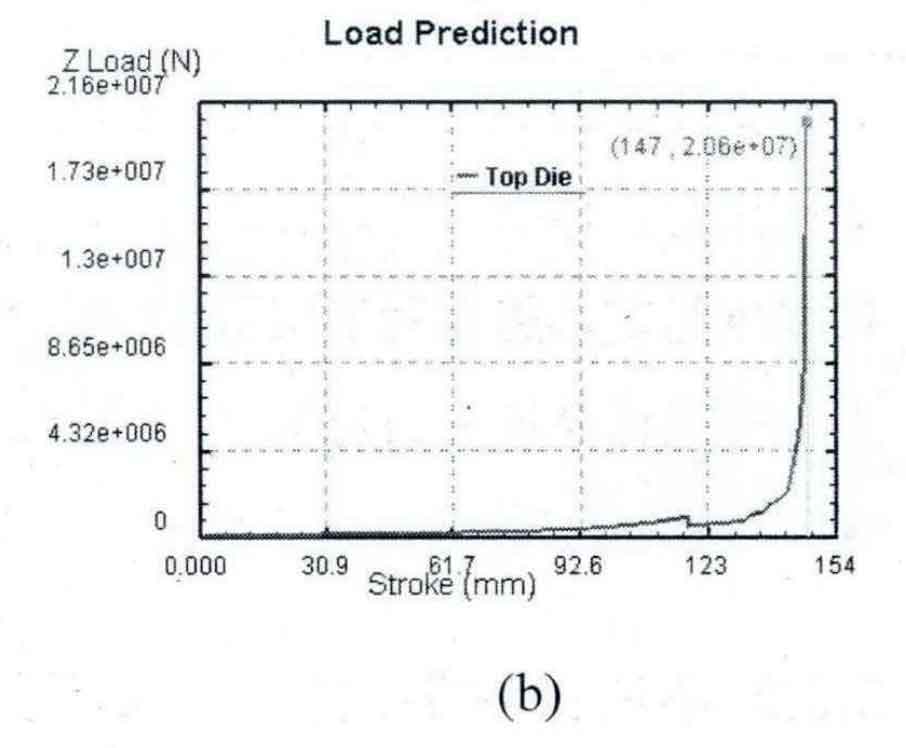

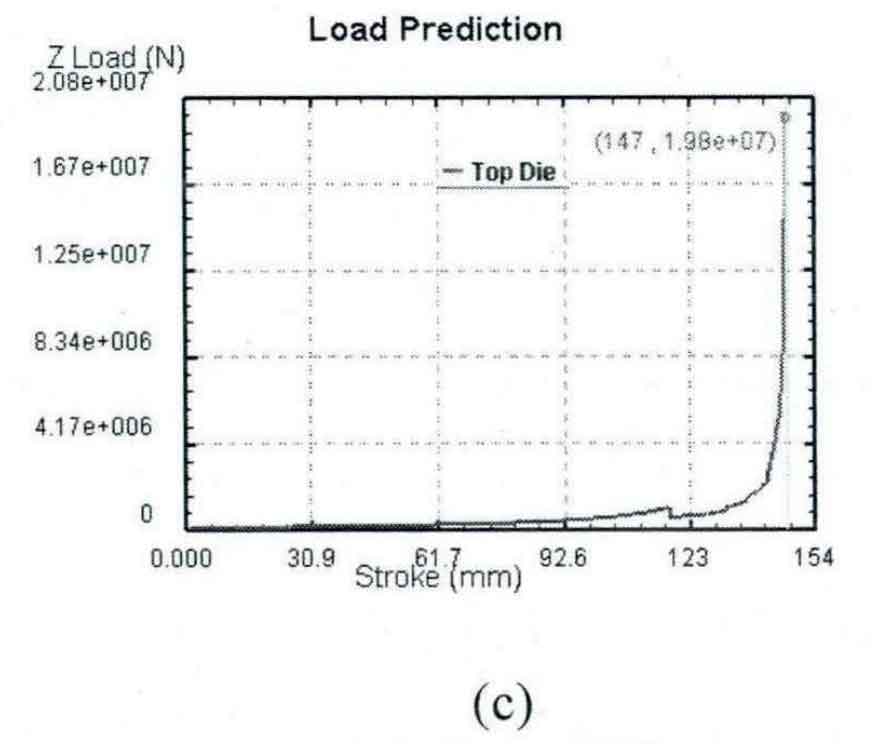

When the friction coefficient is 0.3 and 0.7 respectively, the forming load curve of spiral bevel gear under different initial forging temperatures is shown in Fig. 1 and Fig. 2.

The numerical simulation results are shown in the table.

| Programme | 1 | 2 | 3 | 4 | 5 | 6 |

| Temperature (° C) | 1000 | 1000 | 1050 | 1050 | 1100 | 1100 |

| Friction coefficient | 0.3 | 0.7 | 0.3 | 0.7 | 0.3 | 0.7 |

| Forming load (t) | 15.3 | 20.7 | 15.1 | 20.6 | 14.8 | 19.8 |

It can be seen from Figure 1, figure 2 and table that when the friction coefficient is the same, the higher the initial forging temperature of spiral bevel gear forging, the smaller the forming load required to complete the forging. When the initial forging temperature is the same, the greater the friction coefficient, the greater the forming load required for the forging of spiral bevel gear, and the more difficult it is to form.