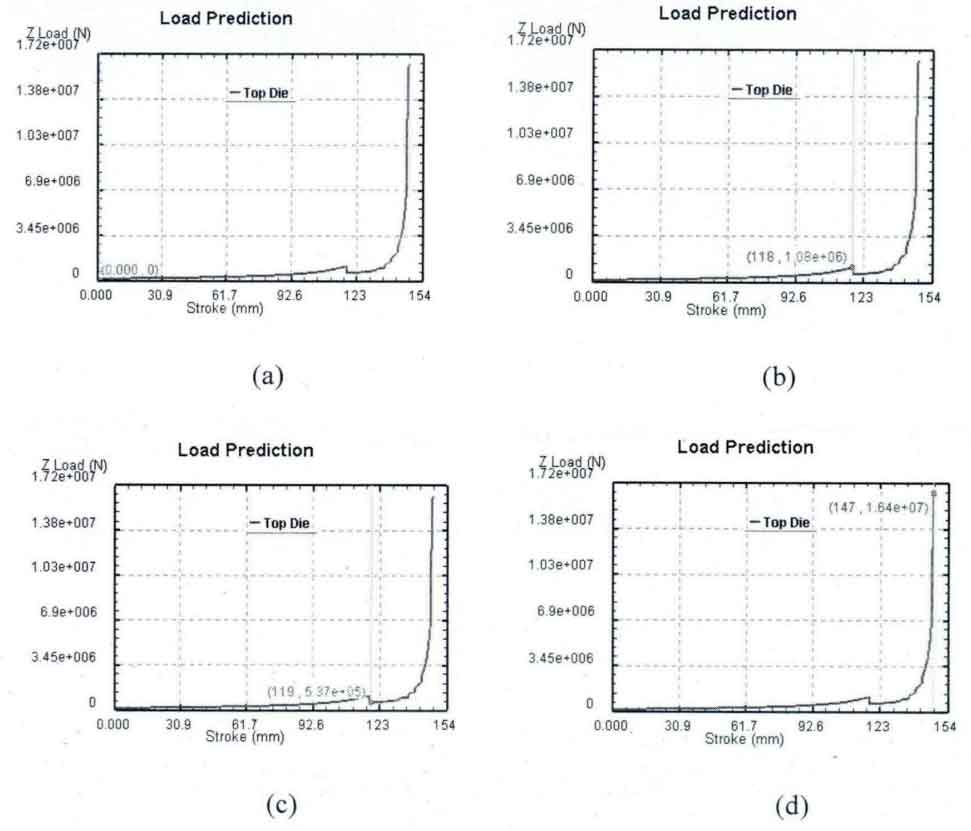

The stroke load curve of the die in the general forging process of spiral bevel gear is shown in the figure. The forming process of spiral bevel gear assembly includes upsetting and die forging.

Figure a shows that the load at the beginning of the upsetting process is 0t. With the progress of the upsetting process, the load gradually increases. When the stroke of the upper die is 118mm, the upsetting process is completed and the forming load reaches 1.08t, as shown in Figure b. After the start of die forging, in step 450, the upper die stroke is 119mm and the load is 0.537t, as shown in Figure c. With the progress of die forging process, the blank of spiral bevel gear is gradually filled into the die cavity. With the increase of filling degree, the deformation resistance and friction resistance gradually increase, and the forming load gradually increases.

When the die cavity is filled, the blank of spiral bevel gear flows to the flash groove, the material flow is difficult, and the forming load increases suddenly. When forging is completed, the stroke of the upper die is 147mm and the forming load is 16.4t, as shown in Figure d.