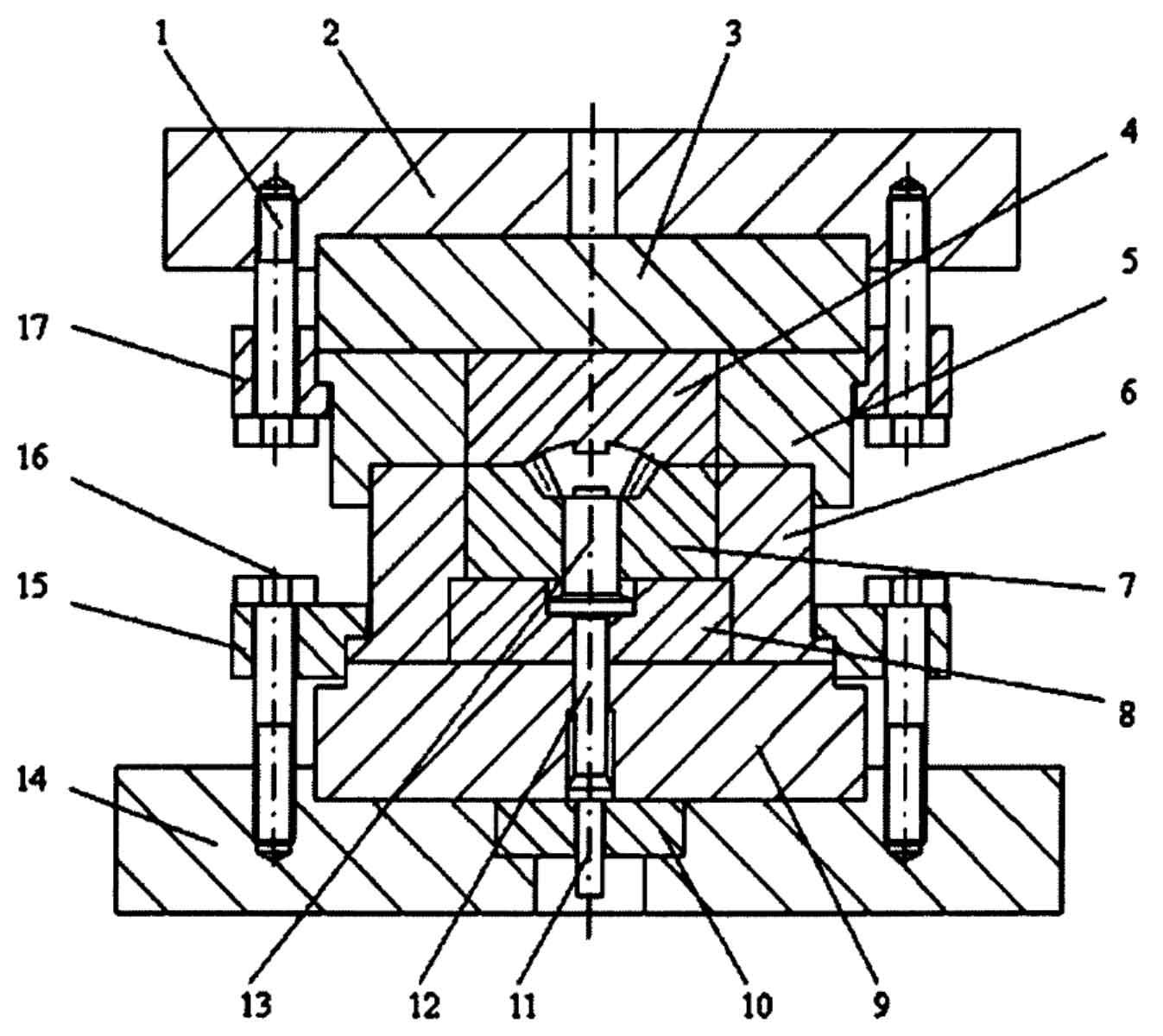

As shown in the figure, the structure diagram of the planetary gear final forging die is given. Since the final forging temperature is lower than the pre forging temperature, the tooth die is designed in the lower die, which will not cause the problem of too high temperature rise of the tooth die. At the same time, it is convenient for the planetary gear forging to align the final forging with the tooth shape. When the planetary gear forging is placed, the deformation of the planetary gear blank is small, the stroke of the sliding block is far less than the lock guide length, and the die adopts lock guide.

The upper base plate 3 and the lower base plate 9 are respectively fixed on the upper template 2 and the lower template 14 with screws. In order to make the figure clear, the screws connecting the upper and lower base plates and the upper and lower templates are not drawn as shown in the figure. The tooth mold 7 and the tooth mold sleeve 6 are prestressed, and the screw 16 uses the lower pressing ring 15 to fix the tooth mold sleeve on the lower template. The back cone formwork 4 and the back cone formwork sleeve 5 are prestressed, and the screw 1 uses the upper pressing ring 17 to fix the back cone formwork sleeve on the upper formwork.

The planetary gear forging starts, the upper die goes down, the gear die sleeve 6 is first introduced into the latch of the back cone die sleeve 5, the upper die continues to go down, the back cone die 4 contacts with the blank, and the planetary gear blank begins to be forged and formed. After forging, the upper die goes up, the forging stays in the lower die, and the planetary gear forging is ejected by the lower ejector of the friction press.