In finite element analysis, the solution efficiency is low and the time cost is greatly increased because the machine tool model is too complex. Therefore, when creating the finite element model, simplify the model according to the following principles:

(1) ignore the geometric features on the machine tool that have little impact on the mechanical properties of the whole machine;

(2) small curvature surfaces such as fillet, chamfer and rounding on machine tool parts, or conical surfaces with small taper, shall be replaced by right angles and planes;

(3) the simplified part has little effect on the volume instead of the complex part.

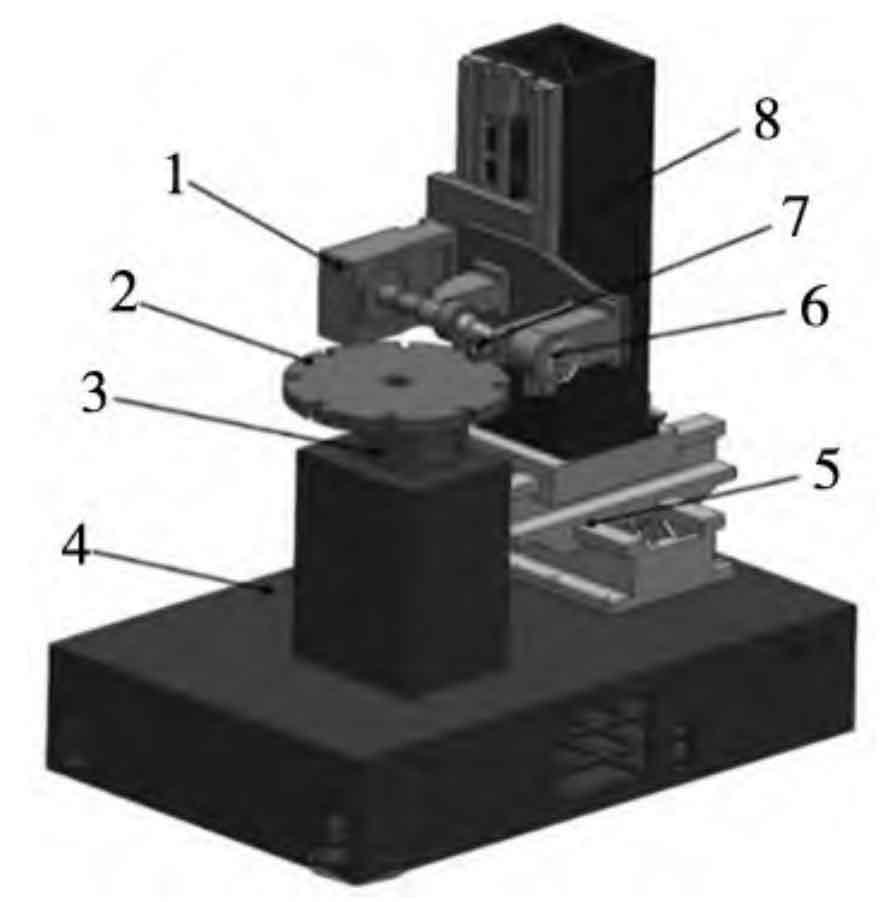

The special machine tool for variable hyperbolic arc tooth line cylindrical gear is mainly composed of spindle, spindle drive reducer, cutter head, bed, indexing reducer, indexing mechanism device, cutter, column slide and cross slide. The three-dimensional modeling of the whole machine assembly is shown in the figure.

The material selection of each part of the machine tool is as follows: the material of the bed is Q235, the material of the cross slide and column slide is HT250, the material of the guide rail and screw rod is GCr15, the material of the gear blank is 40Cr, the material of the cutting tool is w6mo5cr4v2co5, and the other parts are 45 steel. The mechanical properties of each material are shown in the table.

| Name | Density ρ / ( kg·m - 3) | Modulus of elasticity E / GPA | Poisson’s ratio μ |

| HT250 | 7340 | 155 | 0.27 |

| W6Mo5Cr4V2Co5 | 8150 | 230 | 0.3 |

| Q235 | 7850 | 205 | 0.28 |

| GCR15 | 7800 | 208 | 0.3 |

| 45 | 7890 | 209 | 0.269 |

| 40Cr | 7820 | 206 | 0.29 |