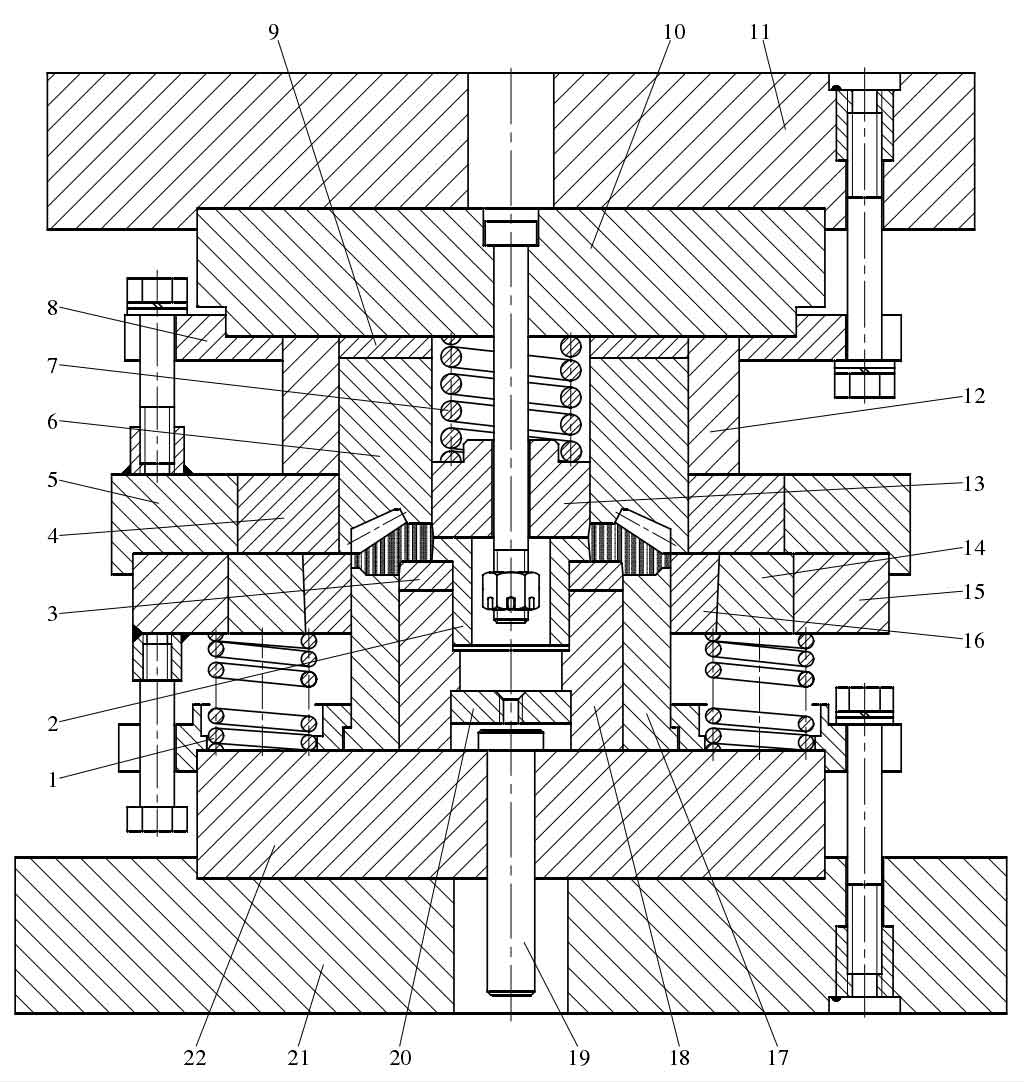

The figure shows the new precision forging die structure of spiral bevel gear. The working part of the die is mainly composed of tooth die 6, female die 16, floating die core 13, fixed die core 2, insert 3 and anvil ring 17. In order to reduce the cost of updating and repairing the die, the tooth die and floating die of the die adopt the combined die structure, and the floating die used in the die can make full use of the friction between the die bore and the blank during the forming of spiral bevel gear forging (the direction of friction force on the blank is consistent with its forming direction), which effectively promotes the flow of metal and reduces the forming force; The blank metal is formed in the closed die chamber, and the spiral bevel gear forging does not produce flash; During mold manufacturing, a series of adjusting pads 9 with the same outer contour size and a thickness difference of 1mm are processed. When the working part of the gear die is worn due to production for a period of time, the cavity of the gear die can be renovated once with a processing amount of 1mm, and then the processing amount can be supplemented by replacing the adjusting pad, so as to avoid replacing the gear die.

The working process of the spiral bevel gear die is as follows: before the upper and lower dies are closed, the floating die core 13 is in the lower limit position under the action of the spring 7, and the combined die is in the upper limit position under the action of the spring 1. Put the heated annular blank into the die and locate it by the insert 3; When the upper die goes down, the combined concave die and the combined tooth die, the floating die core 13 and the fixed die core 2 are combined respectively to form a closed die chamber; The upper die continues to descend, the springs 1 and 7 are compressed, and the blank is formed in the closed die chamber; When the press returns, the upper die goes up, the combined die and floating die core 13 return to the initial position under the action of spring, the formed spiral bevel gear forging remains in the die and is pushed out by the ejector rod 19, top plate 20, anvil ring 17 and insert 3.