In China, the research on the fatigue life of spur gears is mainly based on the method of stress life formula and the method of finite element or fatigue analysis kit.

In 2012, Lin Tengjiao and others used the finite element method to obtain the stress and strain of gears under different loads, and obtained the relationship between the number of load cycles, mean value and amplitude based on the S-N curve. In fe-saef software, they studied the influence of different factors on the fatigue life of gears.

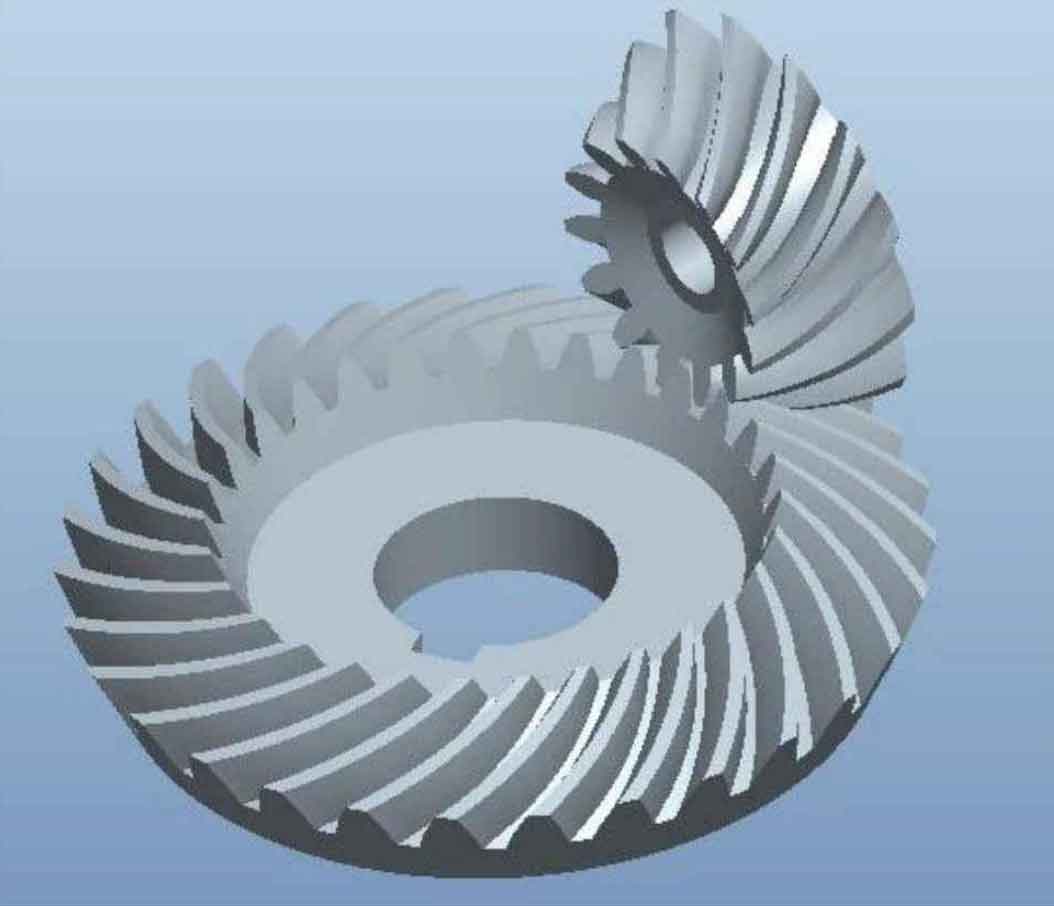

In 2013, Yu biqiang and others obtained the maximum stress at the dangerous section of the gear by using the finite element method, and then obtained the gear bending fatigue life prediction model based on the strain life method. In terms of fatigue research of hypoid gears, for example, in 2010, Zhu cailong used the finite element method to obtain the load of the bevel gear of the main reducer, and used msc Fatigue software and numerical calculation method are used to analyze the gear fatigue, and the prediction results are compared with the bench test. The results show that the software prediction results and numerical results are in good agreement with the experimental results.

In 2014, Ding Sheng calculated the tooth contact stress based on ansi/agma2001-d04 standard, and obtained the predicted value of gear contact fatigue through the S-N curve of gear contact fatigue.

In 2016, Li qiuze and others carried out contact analysis on the tooth surface of spiral bevel gear of high-speed EMU under different loading conditions. With the increase of load, the convex contact area of driven gear moved from the big end of bevel gear to the middle of tooth width; With the increase of load, the concave contact area of driving gear moves from the small end of bevel gear to the middle of tooth width. Finally, it is proposed to adjust the concave contact area of gear to the middle of tooth width to reduce gear pitting.

From the above comparative analysis, it can be seen that there are few studies on bending fatigue of hypoid gear or spiral bevel gear root in China. It takes a lot of time to model when predicting the fatigue of gear root based on fatigue software. The method based on S-N (stress life) curve has been widely used in the design process of gears because of its simple calculation process. However, most studies cannot accurately predict the change of tooth root stress in the meshing process of gear pairs, and the influence of gear support shell deformation is not fully considered in modeling. Therefore, in Chapter 4, this paper will establish a fast prediction method of bending fatigue life of hypoid gear root based on the integral drive axle, and analyze the influence of installation deviation on gear fatigue life.