Research objectives

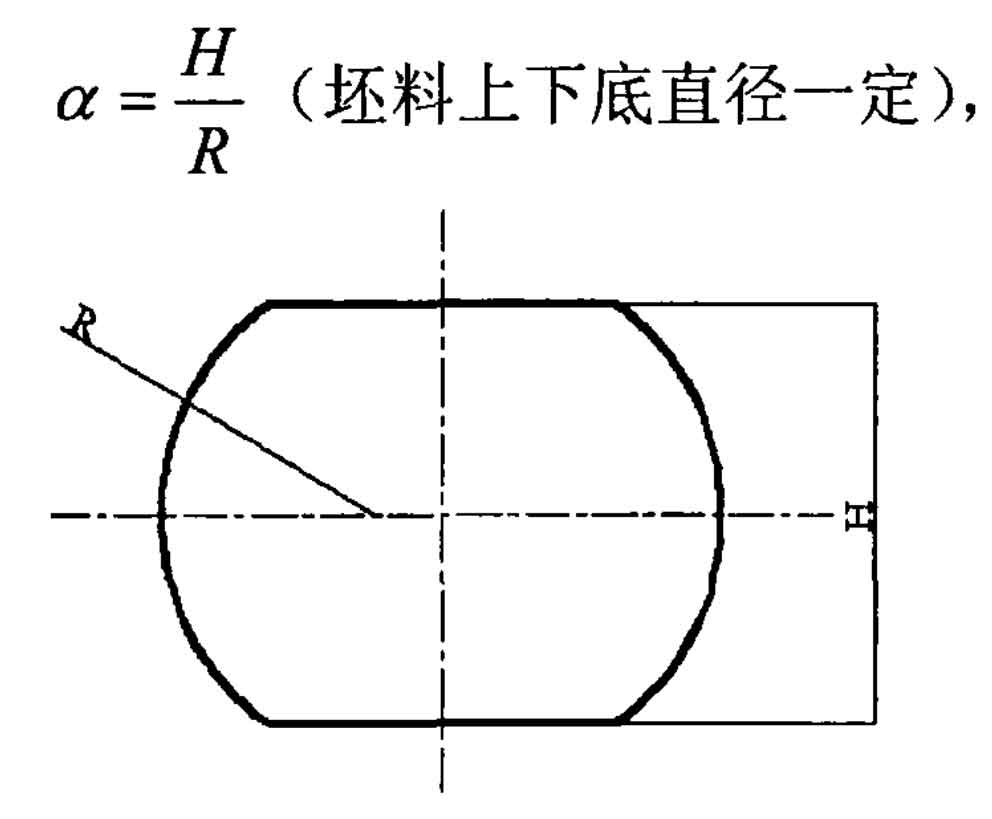

By changing the parameters of the straight bevel gear blank, the forming force energy relationship and the law of metal flow and deformation of the straight bevel gear under different process conditions are studied by using the finite element method, computer and simulation analysis software, so as to obtain the specific methods and parameters to improve the service life of the die and the optimal blank size. The preliminary simulation results show that the drum shape is conducive to forming, A parameter is designed to qualitatively express the design of the blank, as shown in Figure 1.

Research contents

- Study the stress and strain of straight bevel gear in the process of rotary forging.

- Explore the flow law of metal in the process of rotary rolling.

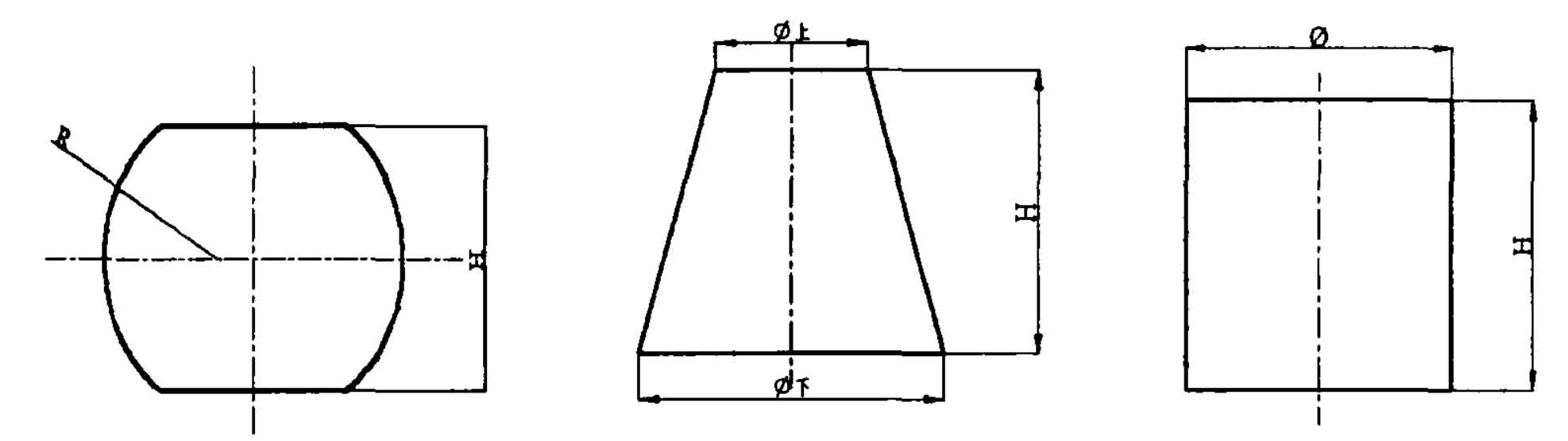

- Study the filling and forming force of different blanks of spur bevel gear under the same forming process parameters, so as to design the most reasonable blank shape and size. The three shapes studied are shown in Figure 2.

- Under the condition of different process parameters, the distribution and variation law of tooth root stress are studied.

Key issues to be solved

This paper reveals the metal flow law and the change law of forming force of spur bevel gear under different parameters, explores the process parameters to reduce the forming force and improve the die life, and obtains the optimal blank shape and size parameters.

Computer numerical simulation will be mainly carried out with Defrom-3D software. Combined with theoretical analysis and experimental methods, the research work is carried out.