Molybdenum disulfide (MoS2), as a high quality solid lubricating material, has good antifriction, antiwear and bearing capacity. Molybdenum disulfide (MoS2) film has a layered structure, and the particles of the deposited film have lower hardness and higher stability.

Using MoS2 to improve the bearing capacity of gear surface has become a research hotspot [38], scholars at home and abroad have done a lot of research. R. I. Amaro et al. Obtained MoS2 lubricating film on spline gear by magnetron sputtering, effectively reduced friction and increased fatigue life limit at high speed. Using MoS2 / Ti composite coating technology can further reduce the friction coefficient, which can b e as low as 0.07 at room temperature, effectively reducing the friction and wear in the operation of friction pairs. R. C. Martins et al. Carried out FZG bench test on the gear coated with molybdenum disulfide composite coating. The temperature and friction coefficient of the gear case with MoS2 coating decreased obviously under the condition of 5-stage load of 3000 R / min. Nissan and Mazda Automobile Company of Japan have researched and applied the technology of surface molybdenum disulfide coating in the development and practice of transmission gear. The main principle is to produce a soft coating of 2 ~ 3 μ m on the tooth surface after the MoS2 film is plated, which can reduce the local maximum meshing contact stress and the surface friction coefficient of the tooth surface, and improve the lubrication condition when the gear is meshed.

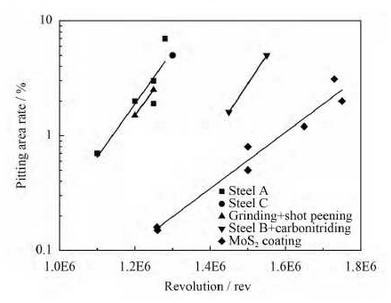

The figure shows the comparison of fatigue life of gears with different materials and gear surfaces coated with molybdenum disulfide (MoS2). In the figure, steel a (1cr-0.4mo) is common gear steel, steel B is vanadium added gear steel, steel C is Mn and Mo incremental gear steel. The test results show that the smoothness of gear surface is obviously improved and the fatigue life is increased more than three times after the gear surface is coated with molybdenum disulfide.