1. Casting technical requirements

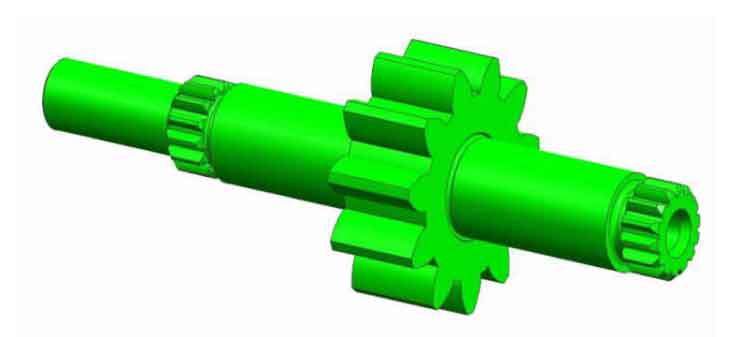

The structure of gear parts of an oil pump is shown in Fig. 1 and Fig. 2 (shaft and disc). Alloy structural steel 12cr2ni4a is adopted. This material is an excellent carburized steel with good hardenability. After carburizing, quenching and low-temperature tempering, it not only has high hardness on the surface, but also has good strength, toughness and plasticity in the core. Therefore, it is especially suitable for manufacturing all kinds of shaft parts and gear parts. The design drawing requires that the roughness of gear shaft diameter surface and tooth side is Ra0 4. The flatness of the end face is 0.005, the cyanidation depth of the external spline is 0.2 ~ 0.4mm, the surface hardness HRC ≥ 56, the cyanidation depth of the gear and shaft diameters at both ends is 0.4 ~ 0.9mm, the surface hardness HRC ≥ 61, and the center hardness hrc32 ~ 43, all of which are secondary cyanidation requirements. When some parts have no internal and external splines, there is only one-time cyanidation requirement.

2. Casting process analysis

The machining process of gear: rough machining → heat treatment → semi finishing machining → magnetic flaw detection → finishing machining → magnetic flaw detection. After chemical heat treatment, the grinding allowance of end face is 0.13 ~ 0.15mm, and the grinding allowance of single side of diameter is 0.15 ~ 0.19mm.