The temperature field distribution of spiral gear die is the key factor of the life of spiral gear die. The temperature distribution of spiral gear die determines the thermal stress distribution in spiral gear die, the degree of thermal stress and the tendency of deformation and crack.

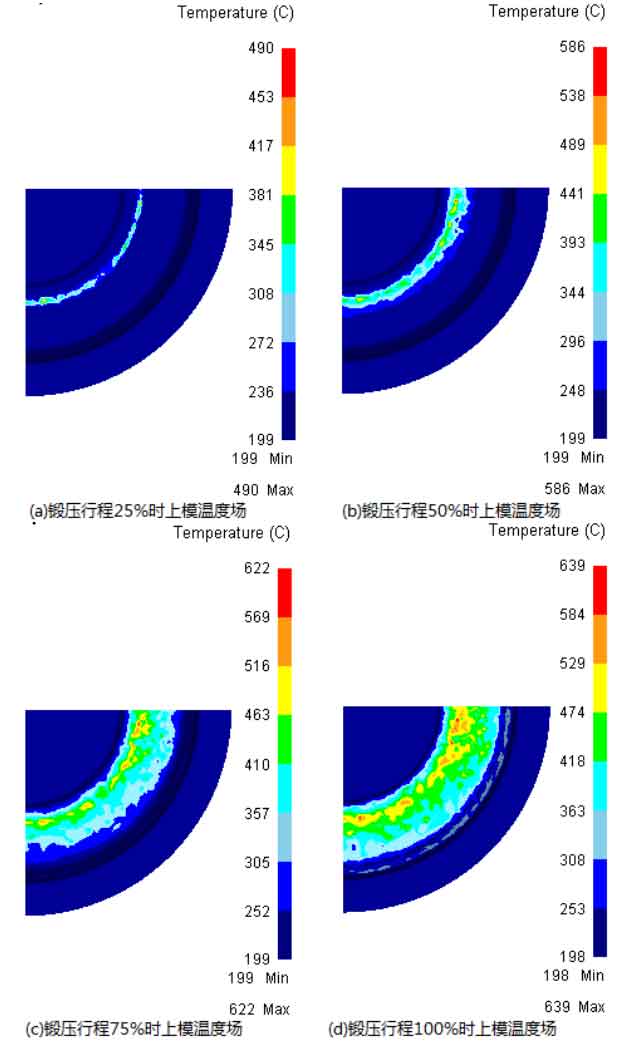

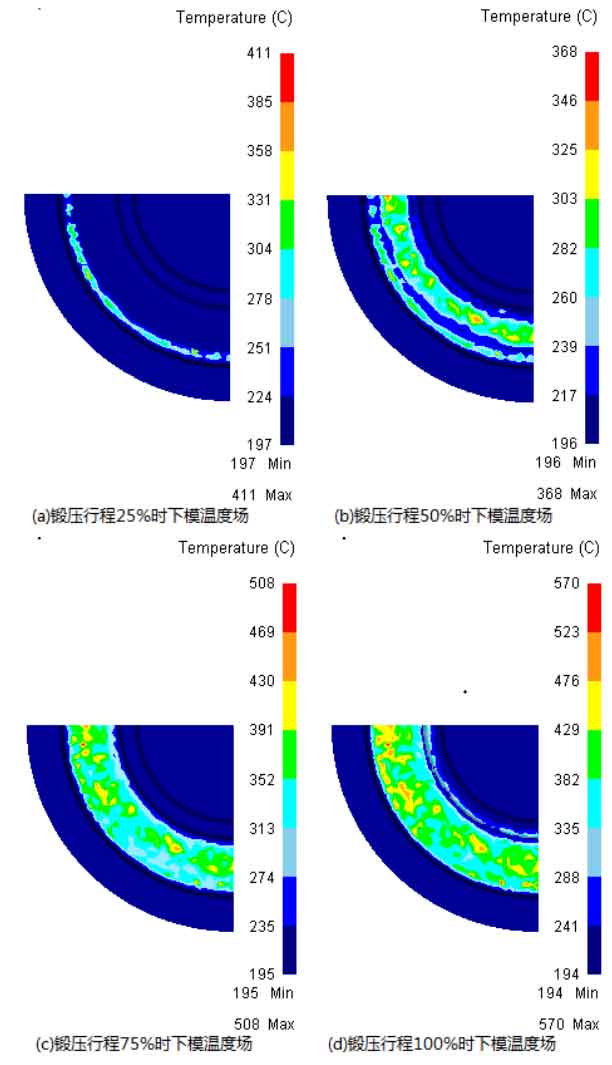

Figure 1 (A-D) and Figure 2 (A-D) show the temperature field distribution of the upper and lower dies when the forging stroke is 25%, 50%, 75% and 100%, respectively. It can be seen from the figure that in the closed die forging process of gear blank, the contact parts and time between spiral gear die and high-temperature blank are different, and the temperature changes of each part are also different. In the whole process, the maximum temperature of the upper die has been in an upward trend, while the lower die has experienced the stage of first rising, then falling and then rising. Due to the short forging time and the parts not in contact with the workpiece, the heat conduction temperature with the surrounding environment does not drop much, and the minimum temperature of the upper and lower dies in the whole process is only 2 ℃ and 6 ℃ lower than the preheating temperature respectively. When the forging stroke is 25%, the upper and lower dies of the helical gear just begin to contact with the high-temperature blank, and the temperature at the contact part rises sharply. The maximum temperature rises from the preheating temperature of 200 ℃ to 490 ℃ and 411 ℃ respectively, with an increase range of 290 ℃ and 211 ℃ respectively. With the forging process, the temperature rise of spiral gear die is slower than before. In the next steps, the change law of the temperature field is basically the same as that at 25% of the stroke, but the parts where the temperature increases and the depth and breadth of the thermal diffusion layer increase significantly. The main area of the temperature rise of the spiral gear die is concentrated in the contact part between the spiral gear die and the high-temperature blank, while the temperature away from the high-temperature blank basically does not change. It can be seen that the main factor of the temperature rise of the spiral gear die in the closed die forging process of the gear blank is the effect of heat conduction.

In the process of closed die forging of driven spiral bevel gear blank, the initial temperature of blank is 1050 ℃. In the forging process, the upper and lower dies are in direct contact with the high-temperature blank, which will increase the temperature of the spiral gear die due to the effect of heat conduction. At the same time, the violent plastic deformation of the blank and the friction between the spiral gear die and the blank will lead to the temperature rise of the spiral gear die. The increase of temperature will reduce the surface hardness of spiral gear die, and even change the size of spiral gear die. The maximum temperature of the die after forging is affected by the initial temperature of the blank, the contact time between the spiral gear die and the blank, the preheating temperature of the spiral gear die and the lubrication conditions.

Through the temperature field change diagram of the spiral gear die in the whole closed die forging plastic forming process, it can be seen that the high-temperature area of the upper and lower die is mainly concentrated in the red area in the figure. At the end of the forging process, the maximum temperature of the upper and lower die surface rises to 639 ℃ and 570 ℃ respectively, 439 ℃ and 370 ℃ higher than the pre heating temperature. Because this part first contacts with the high-temperature blank, the blank metal in contact with this part flows violently and generates a lot of heat, which is transmitted to the spiral gear die through heat conduction, so that the temperature of this part is significantly higher than that of other parts.

If the spiral gear die works under this high temperature and high pressure load for a long time, its thermal stability will be seriously reduced, and the strength of the spiral gear die will be reduced, which is likely to produce plastic deformation and eventually lead to the failure of the spiral gear die. In addition, the high temperature area of this part is concentrated on the surface of the spiral gear die, which will produce compressive stress due to thermal expansion, while the internal material temperature is low, which will produce tensile stress. Due to the effect of internal and external temperature difference, the final result will lead to local fatigue cracks of the spiral gear die. Once the crack occurs, it will continue to extend, and eventually lead to the failure of the spiral gear die.