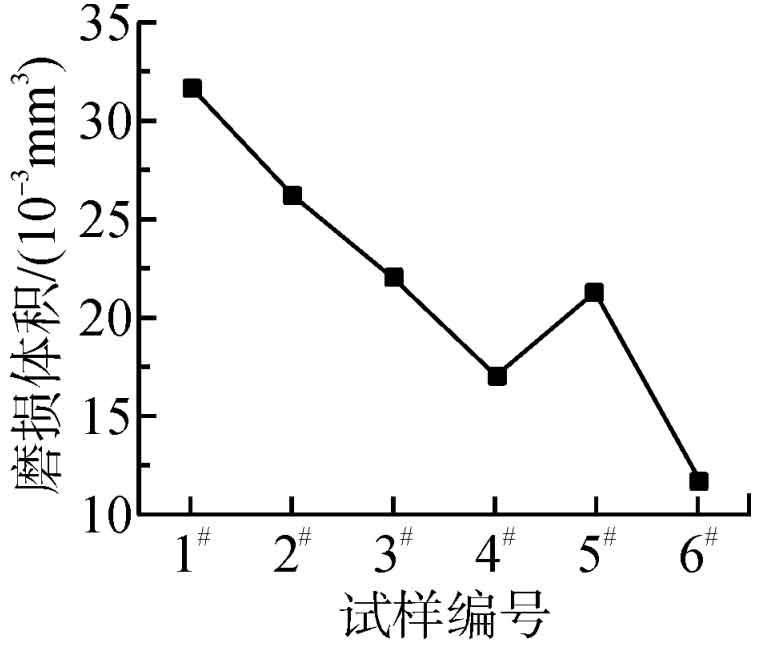

Through experimental verification of the tensile properties of automotive gear forgings, it can be seen that different heat treatment processes can cause varying degrees of changes in the tensile properties of automotive gear forgings. In this study, when using conventional annealing methods to heat treat automotive gear forging blank test samples, with the increase of annealing temperature, the performance changes of test numbers 1 to 5 are as follows: the tensile strength and yield strength of automotive gear forging blank test samples show a trend of first increasing and then decreasing; The elongation after fracture showed a trend of decreasing first and then increasing. When the isothermal annealing method is used to heat treat the test sample of automotive gear forging stock, the performance change of test number 6 is as follows: The tensile strength and yield strength of the test sample of automotive gear forging stock are superior to those processed by conventional annealing method, and its elongation after fracture is smaller than those processed by conventional annealing process. The tensile property test results of automotive gear forging blanks are shown in the figure.

As can be seen from the figure, when conducting heat treatment on automotive gear forging blanks, the annealing temperature should be strictly controlled, and a suitable annealing temperature can improve the tensile properties of automotive gear forging blanks to a certain extent. When using conventional annealing methods to heat treat samples, the annealing temperature should be adjusted to 860 ℃. When isothermal annealing method is used to treat automotive gear forging blanks, the performance of the test samples can be significantly better than that of the test samples processed by conventional annealing methods.

The samples of Test Nos. 4 and 6 were processed using conventional annealing and isothermal annealing methods, and the apparent appearance of Test Nos. 4 and 6 was analyzed using JSM6510 scanning electron microscope. The surface of No. 4 has relatively shallow coarse dimples; The dimples on the surface of No. 6 are significantly reduced and deepened. In summary, the isothermal annealing process is more suitable for the production and manufacturing of automotive gears, which can significantly improve the tensile properties of automotive gears.