1. Test method

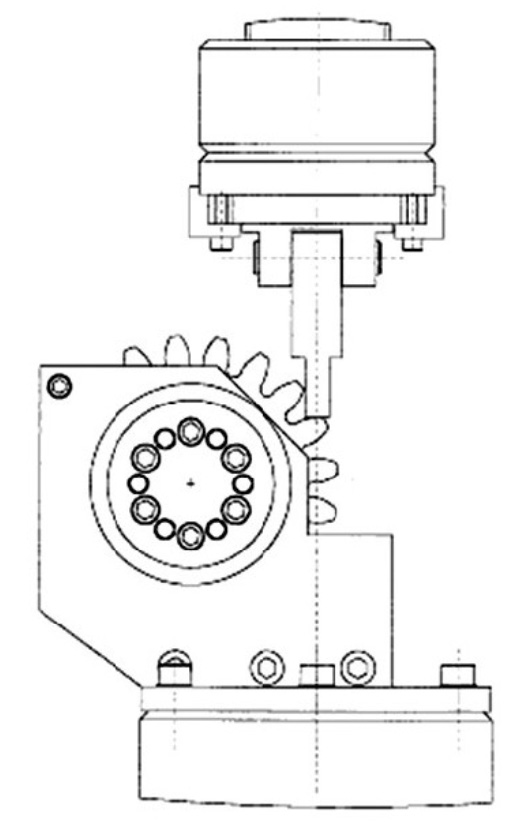

The bending fatigue test fixture of gear material adopts the single tooth loading method shown in Figure 1. In this test method, friction is used to fix the test gear to the tightening torque of the fastening bolt. The test method shall be in accordance with 4.2b gear teeth high frequency pulsating load test method in GB / T 14230-1993 gear bending fatigue strength test method.

2. Basic parameters of test gear

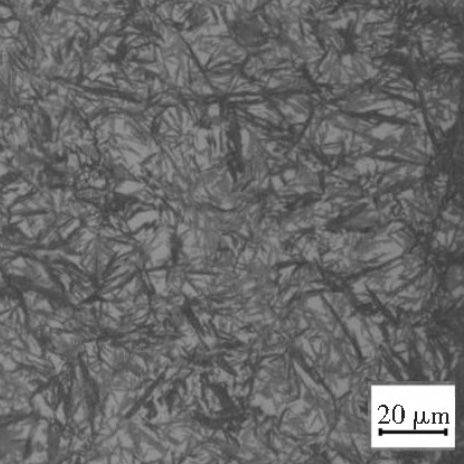

The test gear is spur gear, the material is 20crnimoh, the gear manufacturing process is forging normalizing roughing finishing hobbing carburizing quenching grinding peening, the carburizing temperature is (925 ± 5) ℃, 840 ℃ quenching, 180 ℃ tempering; qzg-1000y hanging shot blasting machine is used for gear shot peening, with shot speed of 80 m / s, shot diameter of 0.8 mm and coverage rate of 200%; the residual stress test equipment is X-ray stress instrument x3003, and the test method is X-ray diffraction method. The main parameters of the test gear, the macro morphology of the test gear are shown in Figure 2, the test results of mechanical properties and chemical composition of the test gear.

3. Test process

The test equipment is Zwick 15 ton high frequency test machine, the test stress ratio R is 0.05, and the test frequency is 105 Hz. In order to compare the fatigue strength and S-N curve slope of shot peened and non shot peened gears, the S-N curves of the two gears were tested and compared. Group method is used to test the inclined section of S-N curve, with more than 5 stress levels and more than 8 grouped data points; lifting method is used to test the fatigue strength limit of curve, with the conditional fatigue limit life of 3 million times and more than 10 effective data.