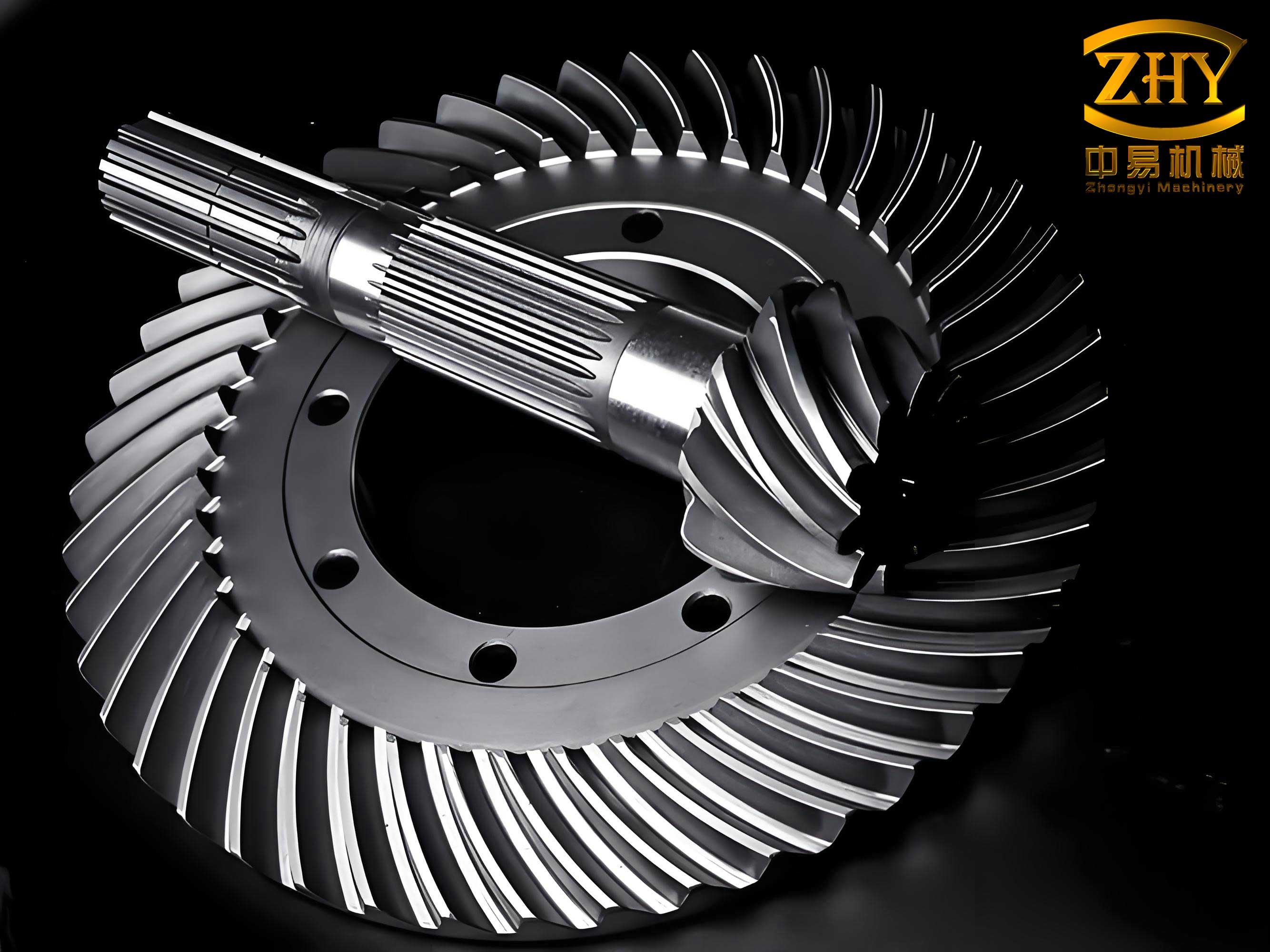

In the realm of power transmission, particularly for applications demanding high torque, compact design, and precise motion control, spiral bevel gears are indispensable components. Their curved teeth allow for gradual engagement and disengagement, resulting in smoother operation, higher load capacity, and reduced noise compared to straight bevel gears. For decades, a significant challenge has been enhancing the durability and performance of these gears under severe operating conditions. The answer lies in hard finishing—post-heat-treatment processes that refine the tooth flanks after they have been hardened. For a significant portion of the industry’s history, the choice was largely between lapping, which is cost-effective but limited in corrective ability, and grinding, which is precise but expensive and slow. From my extensive experience in gear manufacturing, I have witnessed and championed the rise of a third, highly effective path: hard cutting or skiving, often referred to as刮削 (guāxiāo) or hard skiving. This article will delve deeply into the modern hard finishing process for spiral bevel gears, with a particular focus on establishing hard skiving as a superior alternative for a wide range of precision applications.

The fundamental requirement for hard finishing stems from the inevitable distortion that occurs during the hardening process, typically carburizing and quenching. While this process gives spiral bevel gears their essential surface hardness (often 58-62 HRC) and core toughness, it introduces geometric errors. These distortions can degrade the gear’s accuracy by several grades, manifesting as errors in tooth profile, pitch, and alignment. Therefore, a final finishing step is crucial to correct these deviations, achieve the required micro-geometry for optimal contact patterns, and ensure low noise and long service life. The evolution of machine tools, cutting tool materials (especially advanced carbide grades), and CNC control systems has now made the precise machining of hardened steel (typically 60 HRC and above) not only feasible but highly economical.

The complete manufacturing chain for high-performance spiral bevel gears involves a series of critical, interlinked stages. I will outline this process in detail, emphasizing where hard skiving integrates seamlessly.

| Process Stage | Key Objectives & Description | Critical Parameters & Notes |

|---|---|---|

| 1. Gear Blank Machining | To produce the pre-tooth geometry with high-precision reference surfaces (bores, faces, back-angles). | Concentricity and perpendicularity tolerances must be held to within 40% of the final tooth tolerances. This stage sets the foundation for all subsequent accuracy. |

| 2. Soft-Cutting (Roughing & Finishing) | To generate the tooth slots, leaving stock for hard finishing. The final soft-cut gear is the target geometry before distortion. | Cutting parameters, cutter head geometry (cutter radius $$ R_c $$), and machine settings (e.g., machine root angle $$ \gamma_m $$, offset $$ E_m $$) are meticulously calculated and validated via contact pattern check. |

| 3. Contact Pattern Inspection (Pre-HT) | To verify the theoretical tooth contact under light load before hardening. This establishes the “master” pattern. | The contact pattern’s location (heel/toe, flank/flank) and size are recorded. This data is vital for compensating during hard skiving setup. |

| 4. Heat Treatment (Carburizing & Quenching) | To achieve desired surface hardness and core properties. | The single greatest source of distortion. Factors like material homogeneity, part symmetry, and fixturing during quenching must be controlled. Prototyping is often used to predict distortion behavior for critical spiral bevel gears. |

| 5. Reference Surface Finishing | To re-establish precise, clean datums on the hardened blank (e.g., grinding the bore and face). | Essential for accurate relocation in the hard finishing machine. Any error here directly propagates to tooth geometry. |

| 6. Hard Finishing (Skiving/Grinding) | To remove distortion stock and achieve final tooth geometry, surface finish, and contact pattern. | The Core Stage. For skiving: uses a carbide cutter head in a modified gear generator. The gear pair is typically conjugated by finishing the gear first, then using it to derive corrections for the pinion. |

| 7. Final Dimensional & Quality Inspection | To verify all specifications are met. | Includes coordinate measurement, tooth flank topology mapping, single-flank rolling test for transmission error, and contact pattern check under load. Non-destructive testing (e.g., magnetic particle inspection) is also conducted. |

The heart of this discussion is Stage 6. When we speak of hard skiving for spiral bevel gears, we refer to a discontinuous generating process where a carbide-topped cutter head, with a defined number of interrupted cutting edges, meshes with the hardened workpiece in a precisely controlled CNC path. The process mirrors soft cutting but operates on a much harder material. The key to its success is the substitution of a grinding wheel with a much more robust and freely-cutting carbide tool. The material removal in hard skiving is governed by complex kinematics. A simplified view of the cutting speed $$ V_c $$ at a point on the cutter blade can be expressed as a function of the machine’s rotational elements:

$$ V_c = f(\omega_c, \omega_w, R_{cut}, \phi) $$

where $$ \omega_c $$ is the cutter head angular velocity, $$ \omega_w $$ is the workpiece (gear) angular velocity, $$ R_{cut} $$ is the instantaneous cutting radius, and $$ \phi $$ is the phase angle of engagement. The CNC synchronizes these motions to ensure the cutter blade follows the theoretical conjugate path of the tooth flank, removing a controlled stock layer, typically ranging from 0.05mm to 0.2mm per flank.

Advantages of Hard Skiving vs. Traditional Methods for Spiral Bevel Gears

To justify the adoption of hard skiving for spiral bevel gears, a clear, quantitative comparison with established methods is necessary. The following table and analysis detail the distinct advantages.

| Feature | Lapping | Grinding | Hard Skiving (刮削) |

|---|---|---|---|

| Corrective Capability | Very Low. Only improves surface roughness and minor run-in of contact. | Very High. Can correct all forms of geometric error (profile, pitch, helix). | High. Can effectively correct heat treatment distortion for profile, pitch, and lead errors. |

| Material Removal Rate (MRR) | N/A (Abrasive process, no defined chip) | Low. Limited by thermal damage risk. MRR $$ \propto a_e \cdot v_{w} $$, where $$ a_e $$ is small. | Very High. MRR $$ \propto f_z \cdot n_c \cdot a_p $$. Typical depth of cut $$ a_p $$ is an order of magnitude larger than in grinding. |

| Process Time | Short | Very Long (especially for large spiral bevel gears) | Short to Moderate (3-10x faster than grinding for same stock removal) |

| Surface Finish (Ra) | ~0.4 – 0.8 μm | ~0.2 – 0.4 μm | ~0.3 – 0.6 μm (Can achieve <0.5 μm with optimized parameters) |

| Surface Integrity | Generally good, compressive residual stress from plastic flow. | Risk of thermal damage (burning, re-hardening, tensile cracks). | Excellent. Coolant effectively evacuates heat with chips. Minimal thermal input results in no burns or annealing. |

| Residual Stress | Compressive near surface. | Often tensile or near-zero at surface due to thermal effects. | Favorable Compressive. The mechanical cutting action induces beneficial compressive stresses. |

| Tooling/Machine Cost | Low (lapping machine and compound) | Extremely High (dedicated bevel gear grinder) | Moderate. Uses modified gear generators. Cutter heads are expensive but have long life. |

| Process Flexibility | Low | Low (dedicated setup) | High. CNC program can be adapted for different spiral bevel gear designs on same platform. |

The superiority of hard skiving for spiral bevel gears becomes particularly evident when examining surface integrity and residual stress. Grinding, while precise, is a thermally dominated process. The high specific energy and poor thermal conductivity of the abrasive wheel can lead to localized temperatures exceeding the austenitization point, followed by rapid quenching by the coolant. This can create a re-hardened “white layer” and, more detrimentally, subsurface tensile stresses. These tensile stresses act as catalysts for fatigue crack initiation under cyclic loading.

In contrast, hard skiving is a mechanically dominated process. The sharp carbide edge shears the material, and the majority of the process heat is carried away by the chip. The workpiece temperature rise is minimal. Furthermore, the plastic deformation induced by the cutting action ahead of the tool tip creates a layer of compressive residual stress on the tooth flank of the spiral bevel gear. The magnitude of this stress $$ \sigma_{rs}(z) $$ as a function of depth $$ z $$ below the surface can be modeled, though it is highly dependent on tool geometry and cutting parameters:

$$ \sigma_{rs}(z) = \sigma_0 \cdot e^{-kz} $$

where $$ \sigma_0 $$ is the surface compressive stress and $$ k $$ is a decay constant. This compressive layer significantly impedes crack propagation, thereby enhancing the contact fatigue life (pitting resistance) and bending fatigue strength of the spiral bevel gear. This fundamental advantage is a key reason why high-performance automotive differentials and aerospace transmissions are increasingly adopting hard-skived spiral bevel gears.

Technical Implementation and Process Control in Hard Skiving

Successfully implementing hard skiving for spiral bevel gears requires meticulous attention to several key factors beyond simply running a program on a machine.

1. Distortion Analysis and Stock Allowance: The first step is to understand and quantify the hardening distortion. This is often done through statistical process control on a batch or via Finite Element Analysis (FEA) simulation for new designs. The goal is to predict the magnitude and direction of tooth movement to define a uniform, minimal stock allowance for skiving. Non-uniform stock leads to inconsistent tool load and potential premature tool wear or breakage. The stock envelope $$ S(\theta, l) $$ as a function of roll angle $$ \theta $$ and tooth length $$ l $$ should be as consistent as possible.

2. Machine and Tooling: The process requires a rigid, high-precision bevel gear cutting machine with CNC capability for all axes (cradle, workpiece, cutter head tilt, etc.). The cutter heads are specialized. For large-module spiral bevel gears, indexable carbide insert heads are preferred for economy and quick edge replacement. For small-to-medium modules, brazed solid carbide or PcBN-tipped blades are used for higher precision. The cutter head geometry (profile angle, point radius, hook angle) must be optimized for hard cutting. The effective cutting speed $$ V_{c,eff} $$ must be chosen to avoid built-up edge while maximizing productivity, often in the range of 80-200 m/min for modern carbide grades.

3. The Compensation Loop (Gear-Pinion Conjugation): A standard practice in finishing hardened spiral bevel gear sets is the “compensation loop.” The larger gear (often the ring gear) is hard-skived first to its nominal soft-cut geometry. This now-perfect hardened gear becomes the master. The pinion is then cut in the soft state, but the machine settings are deliberately altered (“ease-off” modifications are applied) so that its theoretical unloaded contact pattern is intentionally mismatched. After hardening, the pinion is hard-skived using a different set of corrections (based on the now-known performance of the gear skiving process) designed to bring its flanks into perfect conjugate contact with the finished hardened gear. This iterative, data-driven approach is crucial for achieving the desired loaded contact pattern and low transmission error. The ease-off topography $$ E(M, L) $$ on the pinion, defined in the length (L) and profile (M) direction, is a key design output from this process.

4. Process Stability and Monitoring: Cutting forces during hard skiving of spiral bevel gears are significant. Monitoring these forces (e.g., main drive torque or axial force on the cutter spindle) is essential for detecting tool wear or chipping. Acoustic emission sensors can also signal tool failure. A stable, high-pressure coolant system is non-negotiable for chip evacuation, cooling, and extending tool life.

Quality Assurance and Future Outlook

The final validation of hard-skived spiral bevel gears involves comprehensive metrology. Traditional gear checkers are used for pitch and runout. However, modern practices rely heavily on 3D flank scanning using coordinate measuring machines (CMMs) or dedicated gear scanners. These systems generate a point cloud of the actual tooth surface, which is compared to the nominal CAD model. The deviation map clearly shows the effectiveness of the skiving process in correcting distortion. The transmission error, measured on a single-flank rolling tester, is the ultimate functional metric for noise potential. A well-executed hard skiving process for spiral bevel gears should yield a transmission error curve that is low in amplitude and smooth in character.

| Inspection Parameter | Target Tolerance | Measurement Method |

|---|---|---|

| Tooth-to-Tooth Composite Error | < 15 μm | Single Flank Rolling Tester |

| Total Composite Error | < 30 μm | Single Flank Rolling Tester |

| Surface Roughness (Ra) | < 0.5 μm | Profilometer |

| Flank Form Deviation (Profile, Lead) | < 10 μm | 3D Flank Scanning / CMM |

| Residual Stress at Surface | > -200 MPa (Compressive) | X-ray Diffraction |

Looking ahead, the future of hard finishing for spiral bevel gears is intertwined with further advancements in digitalization and tool technology. The integration of in-process measurement directly on the skiving machine, coupled with adaptive CNC controls that can adjust parameters in real-time based on force or vibration signals, will push consistency and quality to new levels. The development of even more wear-resistant tool coatings and substrate materials (like advanced carbides and composites) will increase skiving speeds and tool life, making the process even more economical. Furthermore, the complete digital twin of the manufacturing process—from blank to finished hardened gear—will allow for perfect first-part success by simulating and compensating for all expected distortions virtually before any physical cutting occurs.

In conclusion, hard skiving has firmly established itself as a transformative technology for the finishing of spiral bevel gears. It successfully bridges the gap between the limited capability of lapping and the high cost of grinding. By offering high precision, excellent surface integrity, superior fatigue performance, and compelling economics, it is the logical choice for manufacturers of high-performance spiral bevel gears across automotive, aerospace, energy, and heavy machinery sectors. As machine tools and cutting technology continue to evolve, the dominance and application range of this powerful hard finishing method for spiral bevel gears will only continue to expand.