Gear shaving contact characteristics critically influence workpiece surface quality. This analysis establishes mathematical and mechanical models of gear shaving based on meshing principles, proposes a meshing contact analysis algorithm, and calculates shaving contact characteristics under varying contact ratios. Finite element method (FEM) validation confirms that normal contact force peaks near the pitch circle during gear shaving. Reduced contact ratios increase normal contact forces, intensifying mesh impact and profile-concave errors.

1 Introduction

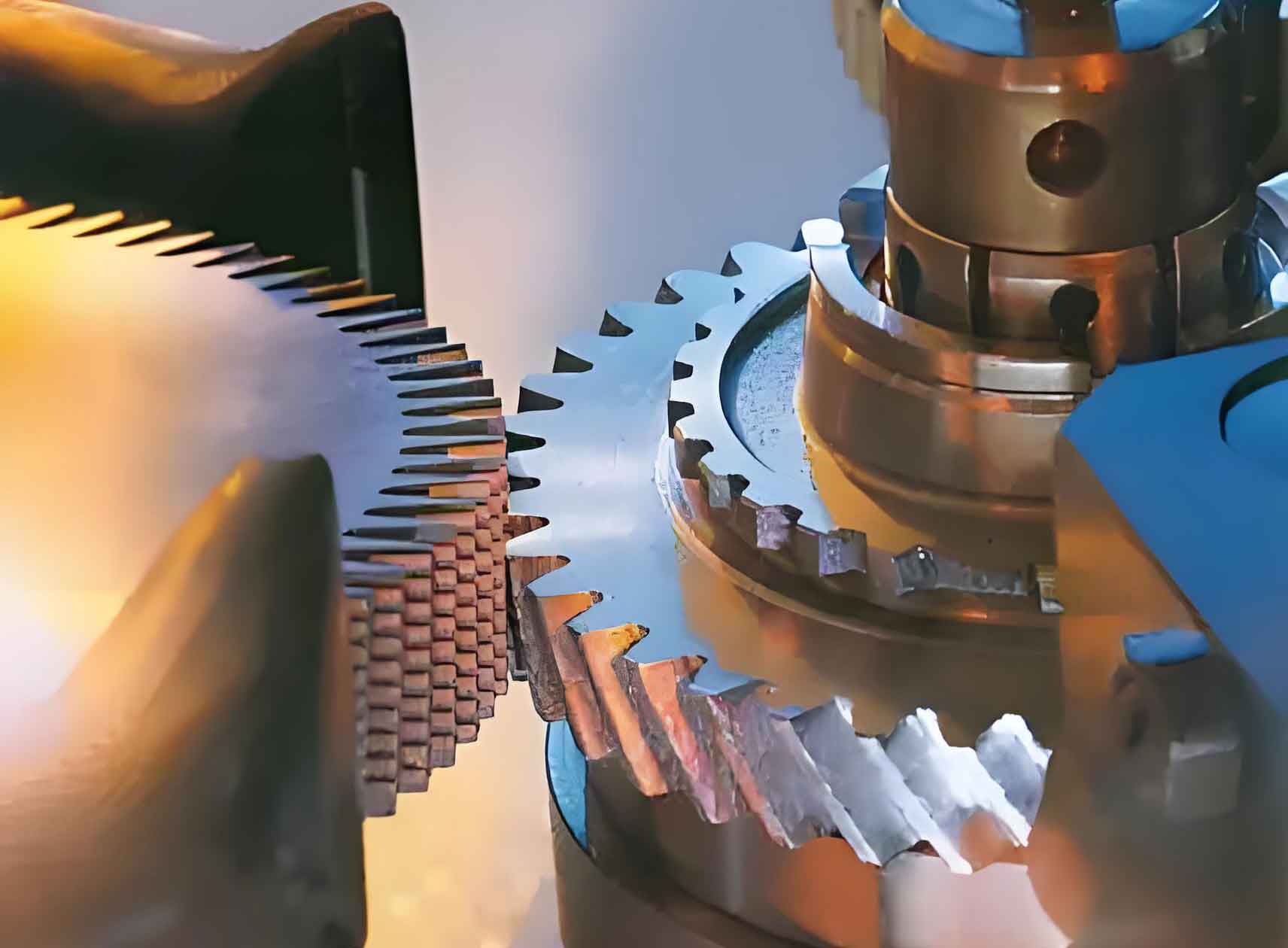

Contact ratio is widely recognized as a primary factor inducing profile-concave errors in gear shaving. During the gear shaving process, instantaneous point contact occurs between the shaving cutter and workpiece gear. Non-integer contact ratios cause abrupt changes in contact point counts near the pitch circle, creating unbalanced contact lines that elevate cutting forces. This excessive material removal manifests as pronounced profile-concave errors. Existing literature extensively applies Loaded Tooth Contact Analysis (LTCA) to modified helical gears and develops Enhanced Tooth Contact Analysis (ETCA) incorporating machine tool errors. However, these models often neglect the influence of chip flutes and cutting edges on cutter surfaces. This study integrates Hertz theory and gear machining principles to establish a comprehensive contact analysis framework for gear shaving, quantitatively evaluating how contact ratio affects meshing dynamics and error formation.

2 Mathematical Model of Gear Shaving

2.1 Gear Shaving Meshing

Gear shaving remains one of the most prevalent finishing processes for enhancing tooth surface quality. When meshing occurs at the cutting edges bordering chip flutes, unequal normal velocities ($v_{1n} \neq v_{2n}$) enable edge penetration into the workpiece. Simultaneously, tangential velocity differences ($v_{1t} \neq v_{2t}$) generate relative sliding motion, where the shaving speed $v_t^{(12)} = v_{1t} – v_{2t}$ facilitates material removal. Workpiece axial reciprocation ensures complete surface coverage. The spatial meshing relationship between cutter and workpiece is geometrically modeled as follows:

2.2 Mathematical Formulation

2.2.1 Shaving Cutter Tooth Surface Equation

Distinct from helical gears, shaving cutters feature strategically arranged chip flutes and cutting edges. For a right-hand flank in coordinate system $O_1X_1Y_1Z_1$, the surface equation is:

$$ \begin{cases}

x_1 = -r_{b1} \sin(u_1 – \lambda_1) + r_{b1} u_1 \cos(u_1 – \lambda_1) \\

y_1 = r_{b1} \cos(u_1 – \lambda_1) + r_{b1} u_1 \sin(u_1 – \lambda_1) \\

z_1 = p_1 \lambda_1, \quad \lambda_1 \in \left[0, \frac{b_1 \cos\beta}{r_{b1} \cot\beta_{b1}\right] \cup \bigcup_{t=1}^{N} \left[\frac{(b_1 + (t-1)L + k) \cos\beta}{r_{b1} \cot\beta_{b1}}, \frac{(b_1 + tL) \cos\beta}{r_{b1} \cot\beta_{b1}}\right]

\end{cases} $$

where $r_{b1}$ = base circle radius, $u_1$ = pressure angle + unwind angle, $p_1 = r_{b1} \cot\beta_{b1}$ = spiral parameter, $\beta_{b1}$ = base circle helix angle, $\beta$ = pitch circle helix angle, $\lambda_1$ = rotation angle along Z-axis, and $b_1, L, k$ = chip flute parameters.

2.2.2 Shaving Meshing Equation

The meshing process adheres to classical theory, requiring relative velocity and normal vector orthogonality at contact points:

$$ \mathbf{v}^{(12)} \cdot \mathbf{n} = 0 $$

Solving Equation (2) yields the meshing surface equation:

$$ \begin{cases}

x = x_0 \cos(\lambda_1 + \phi_1) – y_0 \sin(\lambda_1 + \phi_1) \\

y = x_0 \sin(\lambda_1 + \phi_1) + y_0 \cos(\lambda_1 + \phi_1) \\

z = p \theta

\end{cases} $$

For crossed-axis helical gear meshing, contact occurs at points to maximize localized stress. The meshing line equation is:

$$ \frac{x – r_{b1} c_0^2}{-r_{b1} \sqrt{1 – c_0^2}} = \frac{y – r_{b1} \sqrt{1 – c_0^2}}{r_{b1} c_0^2} = \frac{z – \lambda_0 r_{b1}^2 / p_1}{-r_{b1}^2 / p_1} = u_1 $$

where $c_0 = \cos(u_1 – \lambda_1 – \phi_1)$ is constant.

2.2.3 Workpiece Gear Tooth Surface Equation

Radial feed discretization enables time-varying center distance calculation per cutter revolution. The shaving meshing center distance at step $N$ is:

$$ a_N = a – \frac{60N f_r}{n} $$

where $f_r$ = radial feed velocity, $n$ = cutter speed. Workpiece tooth surfaces satisfy backlash-free meshing conditions. In coordinate system $S_2$, the time-varying surface equation is:

$$ \begin{cases}

x_2 = \left[ r_{b1} \left( \cos(u_1 – \lambda_1 – \phi_1) + u_1 \sin(u_1 – \lambda_1 – \phi_1) \right) + a_N \right] \cos(i_{21} \phi_1 + i” l_2) \\ \quad + \left[ r_{b1} \left( \sin(u_1 – \lambda_1 – \phi_1) – u_1 \cos(u_1 – \lambda_1 – \phi_1) \right) \cos\Sigma – p \lambda_1 \sin\Sigma \right] \sin(i_{21} \phi_1 + i” l_2) \\

y_2 = -\left[ r_{b1} \left( \cos(u_1 – \lambda_1 – \phi_1) + u_1 \sin(u_1 – \lambda_1 – \phi_1) \right) + a_N \right] \sin(i_{21} \phi_1 + i” l_2) \\ \quad + \left[ r_{b1} \left( \sin(u_1 – \lambda_1 – \phi_1) – u_1 \cos(u_1 – \lambda_1 – \phi_1) \right) \cos\Sigma – p \lambda_1 \sin\Sigma \right] \cos(i_{21} \phi_1 + i” l_2) \\

z_2 = r_{b1} \sin(u_1 – \lambda_1 – \phi_1) \sin\Sigma + p_1 \lambda_0 \cos\Sigma + \frac{r_{b1}^2 i”}{i_{21}} u_1 – l_2

\end{cases} $$

where $\lambda_0$ is a constant derived from:

$$ \lambda_0 = \frac{i_{21} \cot(u_1 – \lambda_1 – \phi_1)(r_{b1}^2 + a_N p_1 \cot\Sigma)}{i_{21} r_{b1}^2} + \frac{r_{b1} \csc(u_1 – \lambda_1 – \phi_1)(a_N i_{21} + i_{21} p_1 \cot\Sigma – p_1 \csc\Sigma)}{i_{21} r_{b1}^2} $$

3 Analysis of Shaving Contact Characteristics

3.1 Shaving Contact Characteristics

Contact characteristics focus on normal force $f_n$, Hertzian stress $\sigma_H$, and elastic deformation $\delta_E$ between cutter and workpiece. While bending stresses act on gear teeth, their minimal influence on surface deformation justifies exclusion from this analysis.

3.2 Contact Ratio

Contact ratio quantifies simultaneous tooth pair engagement during gear shaving. For crossed-axis helical gear meshing with point contact, transverse, overlap, and total contact ratios converge to:

$$ \varepsilon_n’ = \frac{l + \Delta l}{\pi m_n \cos\alpha_n \cos\beta_{b1}} $$

where $l$ = transverse contact length, $\Delta l$ = transverse contact length extension. Varying contact ratios alter cutter tip geometry, curvature radii, and meshing dynamics, directly impacting maximum normal contact forces during gear shaving.

3.3 Shaving Meshing Contact Analysis Algorithm

3.3.1 Tooth Profile Contact Points

Meshing paths on cutter surfaces are discontinuous; contact at chip flutes shifts to cutting edges where curvature radii change abruptly. This curvature variation modifies normal forces, influencing material removal and profile-concave errors. Projecting the cutter base circle onto workpiece transverse plane $O_Px_Py_P$ yields an ellipse:

$$ \frac{x_P^2}{(r_{b1} / \cos\Sigma)^2} + \frac{(y_P – a)^2}{r_{b1}^2} = 1 $$

Transforming Equation (7) into coordinate system $S_P$ and projecting onto plane $O_Px_Py_P$ gives the workpiece transverse tooth profile. Continuous cutter rotation necessitates dynamic profile updates via coordinate transformation:

$$ \begin{bmatrix} x_p \\ y_p \\ z_p \\ t_p \end{bmatrix} = \mathbf{M}_{p2} \begin{bmatrix} x_2 \\ y_2 \\ z_2 \\ t_2 \end{bmatrix} $$

Intersecting this profile with the meshing line identifies contact points.

3.3.2 Solving Normal Force, Stress, and Strain

Static equilibrium equations resolve normal forces for 2 or 3-point contact. For 4-point contact, force and moment equilibrium require supplemental compatibility conditions:

$$ \begin{cases}

F_1 \sin\alpha + F_2 \sin\alpha + F_3 \sin\alpha + F_4 \sin\alpha = F_r \\

F_1 \cos\alpha + F_2 \cos\alpha = F_3 \cos\alpha + F_4 \cos\alpha \\

F_1 \cos\alpha L_1 + F_2 \cos\alpha L_2 = F_3 \cos\alpha L_3 + F_4 \cos\alpha L_4 \\

\frac{P_1}{b_1} + \frac{P_2}{b_2} = \frac{P_3}{b_3} + \frac{P_4}{b_4}

\end{cases} $$

where $b_i$ = semi-major axis of contact ellipses. Compatibility ensures equal cumulative deformation across contact lines. Normal stress $\sigma_H$ is then calculated as:

$$ \sigma_H = Z_H Z_e Z_E Z_\beta \sqrt{\frac{\cos\alpha_t \cos\beta}{d_1 b} \cdot \frac{u + 1}{u} \cdot F_n \cdot K_H} $$

where $u$ = transmission ratio, $F_n$ = normal force, $Z_H, Z_e, Z_E, Z_\beta$ = mesh coefficients, and $K_H = K_A K_V K_{H\alpha} K_{H\beta}$ = load factor. Contact deformation $\delta_E$ follows elastic cylinder theory:

$$ \delta_E = \frac{(1 – \nu^2) F_n}{E \pi} \left( \frac{1}{2} + 2 \ln 2 + \ln \sqrt{\frac{L}{b}} \right) $$

where $E$ = Young’s modulus, $\nu$ = Poisson’s ratio, $L$ = face width.

3.4 Shaving Meshing Contact Characteristics Calculation

Profile-concave errors predominantly occur at contact ratios below 2. Four shaving cutters were designed against a common workpiece gear to achieve distinct contact ratios. Material properties and cutter parameters are listed below:

| Parameter | Shaving Cutter | Workpiece Gear |

|---|---|---|

| Material | W18Cr4V | 20CrMnTi |

| Density (kg/m³) | 7800 | 7800 |

| Poisson’s Ratio | 0.3 | 0.25 |

| Young’s Modulus (MPa) | 218,000 | 206,000 |

| Parameter | Workpiece Gear | Cutter 1 | Cutter 2 | Cutter 3 | Cutter 4 |

|---|---|---|---|---|---|

| Teeth Number | 17 | 53 | 52 | 53 | 52 |

| Module (mm) | 4.2333 | – | – | – | – |

| Pressure Angle | 20° | 15° | 15° | 10° | 10° |

| Helix Angle | – | – | – | – | – |

| Profile Shift Coefficient | 0.0468 | -0.3793 | -0.3744 | -0.3649 | -0.3603 |

| Contact Ratio | – | 1.8294 | 1.7712 | 1.7133 | 1.6548 |

Contact analysis reveals stepwise variations in normal force, stress, and deformation due to contact point mutations. Two-point contact (DE segments) exhibits higher force/deformation per point than three-point contact (CD segments) despite equivalent radial forces, as force imbalances in three-point regions promote plastic deformation. Stress-strain curves for Cutters 1-2 (higher contact ratios) demonstrate marginal differences, indicating diminishing returns beyond optimal contact ratios. Critically, lower contact ratios amplify normal forces, stresses, and deformations near the pitch circle (Figure 3), accelerating plastic deformation accumulation and profile-concave error formation during gear shaving.

4 Simulation Validation

4.1 Finite Element Simulation Preprocessing

Hypermesh discretizes the gear shaving model using reduced-integration elements for enhanced distortion tolerance and computational efficiency. Localized modeling satisfies engineering accuracy requirements per Celik’s verification. Key simulation settings include: 1) Dynamic Explicit analysis step with Nigeom=On to manage rigid rotations; 2) Rigid body constraints on cutter components; 3) 200 RPM angular velocity on cutter; 4) Time scaling factor=0.5 to control wave propagation errors.

4.2 Data Comparison

FEM results confirm contact stress mutations during meshing phase transitions (Figure 4). Stress stabilization occurs in three-point contact zones near the pitch circle. Average stresses for Cutters 1-4 are 618.076 MPa, 622.400 MPa, 665.865 MPa, and 681.963 MPa, respectively. Decreasing contact ratios nonlinearly increase maximum shaving stresses. FEM consistently exceeds analytical predictions with deviations of 9.539%, 8.775%, 7.308%, and 0.268%, validating the gear shaving contact algorithm for engineering applications.

5 Conclusion

- Lower contact ratios in gear shaving elevate maximum normal contact forces near the pitch circle during three-point meshing, intensifying localized material removal and profile-concave errors.

- Excessive contact ratios minimally enhance shaving performance but risk undercutting and root interference due to reduced center distances.

- FEM verifies stress concentration in three-point contact regions, with deviations below 10% from analytical models, confirming algorithm reliability.