The pitting point is a kind of fatigue defect, which occurs when small particles on the gear fall off from the tooth surface. When the surfaces of meshing gears are in contact, the repeated stresses on these surfaces can cause pockmarks. They start along the contact line, which is the place with the largest pressure on the teeth of the mating parts, generally due to the excessive load. Fatigue cracks often start in the pockmarked area. Spalling is a serious form of further development of pockmarks, and a part of the gear may crack. The fracture of carburized layer is usually the crack along the tooth surface. It is often caused by excessive working load.

The “correction” pockmarks in the off-axis pinion are made up of very small pits, which will not develop beyond the initial stage, and will often “heal” and become better.

The pockmarks begin at the outer end of the spiral surface (the right side of the gear in this figure), because the center line is slightly misaligned, and the pockmarks slowly progress toward the middle of the gear. Finally, the progress stops, and the surface begins to polish, indicating that the load distribution along the gear surface becomes more uniform. This kind of pockmarks are harmless.

In contrast to the above, the harmful pockmarks shown in the figure are caused by excessive load.

The pockmarks destroy the tooth surface of the gear.

The pockmarks occur at the root contact and the heavy contact occurs at the pockmarks because the overloaded teeth do not engage properly.

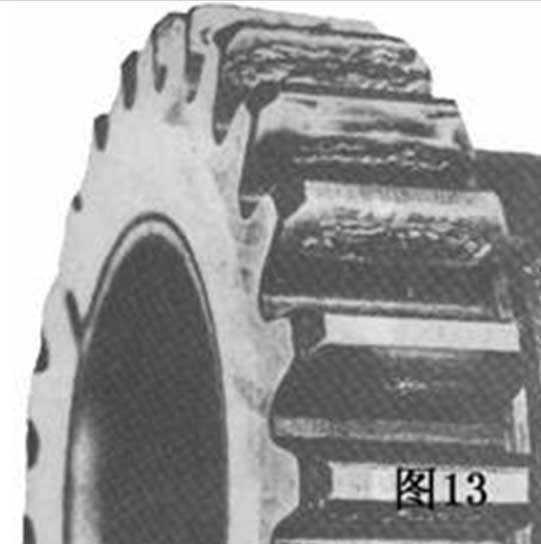

The driving pinion has serious pitting and peeling, and the gear teeth are completely destroyed.

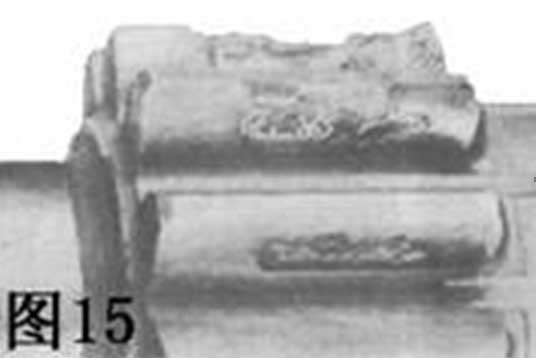

The cemented layer (hardened surface) is crushed, which shows that the contact surface of the bevel gear is a longitudinal crack. The main crack starts from the depth of the structure of the cemented layer center and extends slowly to the surface.

The initial form of cemented layer crushing of carburized gears (gears with heated surface, transformed into high carbon steel and then hardened by quenching) is shown on the left side, and the final stage is shown on the right side. This gear is caused by overload, so it is necessary to make metallographic analysis to determine the possible cause of failure.