Hypoid gear is advanced type of gear widely used in various mechanical systems for their efficiency and strength. Understanding their mechanics involves looking at their design, function, and efficiency.

Design

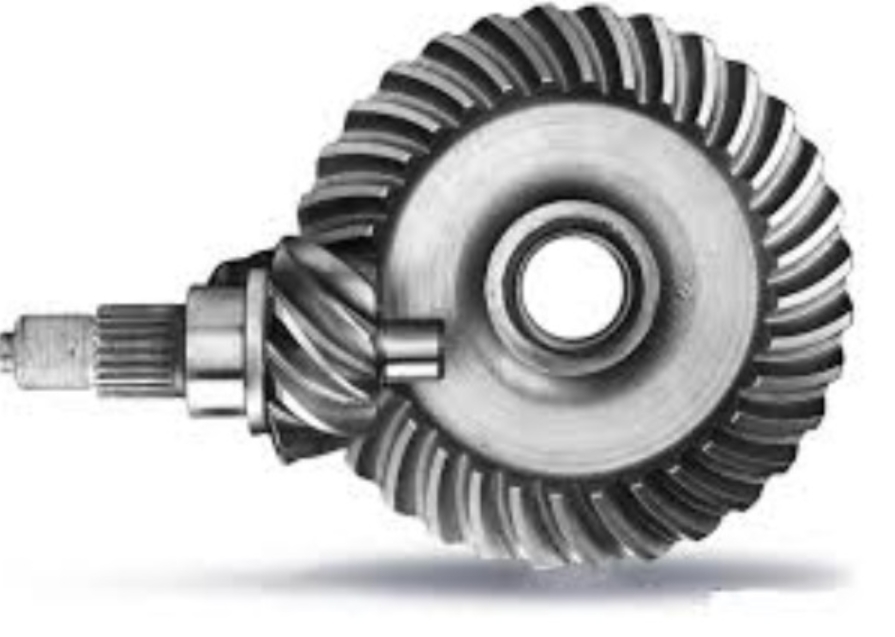

- Geometry: Hypoid gear is a type of bevel gear where the axis of the pinion (the smaller gear) is offset from the axis of the gear (the larger gear). Unlike standard bevel gear, which have intersecting axes, the axes in hypoid gear do not intersect.

- Tooth Profile: The teeth on hypoid gear is typically helical, which allows for smoother engagement and operation. This helical design also contributes to the higher load capacity and quieter operation.

- Offset Design: The offset allows for larger diameter pinions, increasing the contact area between gears. This design is crucial for distributing the load over a larger surface area, thereby increasing strength and durability.

Function

- Torque Transfer: Hypoid gear is primarily used for transferring torque and motion between non-parallel, non-intersecting shafts. The offset design allows for a more significant mechanical advantage, permitting the transmission of higher torque.

- Speed Reduction and Direction Change: They are often used in applications requiring speed reduction and change in rotation direction. Hypoid gear ratio, which is the ratio of the number of teeth between the gear and pinion, determines the magnitude of speed reduction.

- Differential in Vehicles: A common application is in the differential of rear-wheel-drive vehicles, where they allow the wheels to rotate at different speeds while turning, improving traction and handling.

Efficiency

- High Load Capacity: Due to the increased surface contact between the teeth, hypoid gear can handle greater loads compared to standard bevel gears, making them more efficient in heavy-duty applications.

- Reduced Noise and Vibration: The gradual engagement of the teeth, thanks to their helical design, leads to a significant reduction in noise and vibration, which is a crucial factor in automotive and industrial applications.

- Compactness: The non-intersecting shaft design enables a more compact gear arrangement, beneficial in applications with space constraints.

- Lubrication Requirements: Hypoid gear require special lubrication due to the sliding motion of the teeth, which can lead to higher friction and heat generation. Using the right lubricant is crucial for maintaining efficiency and longevity.

- Thermal Efficiency: Despite their higher frictional losses compared to straight-cut gears, hypoid gear is often more thermally efficient in their common applications, primarily because they are typically used in lower-speed, higher-torque settings.

Conclusion

Hypoid gear technology stands out in mechanical engineering for its unique ability to transfer high torque loads efficiently in compact spaces while minimizing noise and vibration. These properties make them highly suited for automotive differentials, heavy machinery, and other applications requiring robust and efficient power transmission between non-aligned shafts. The continued refinement and optimization of hypoid gear design and materials further enhance their efficiency and application scope in modern engineering.