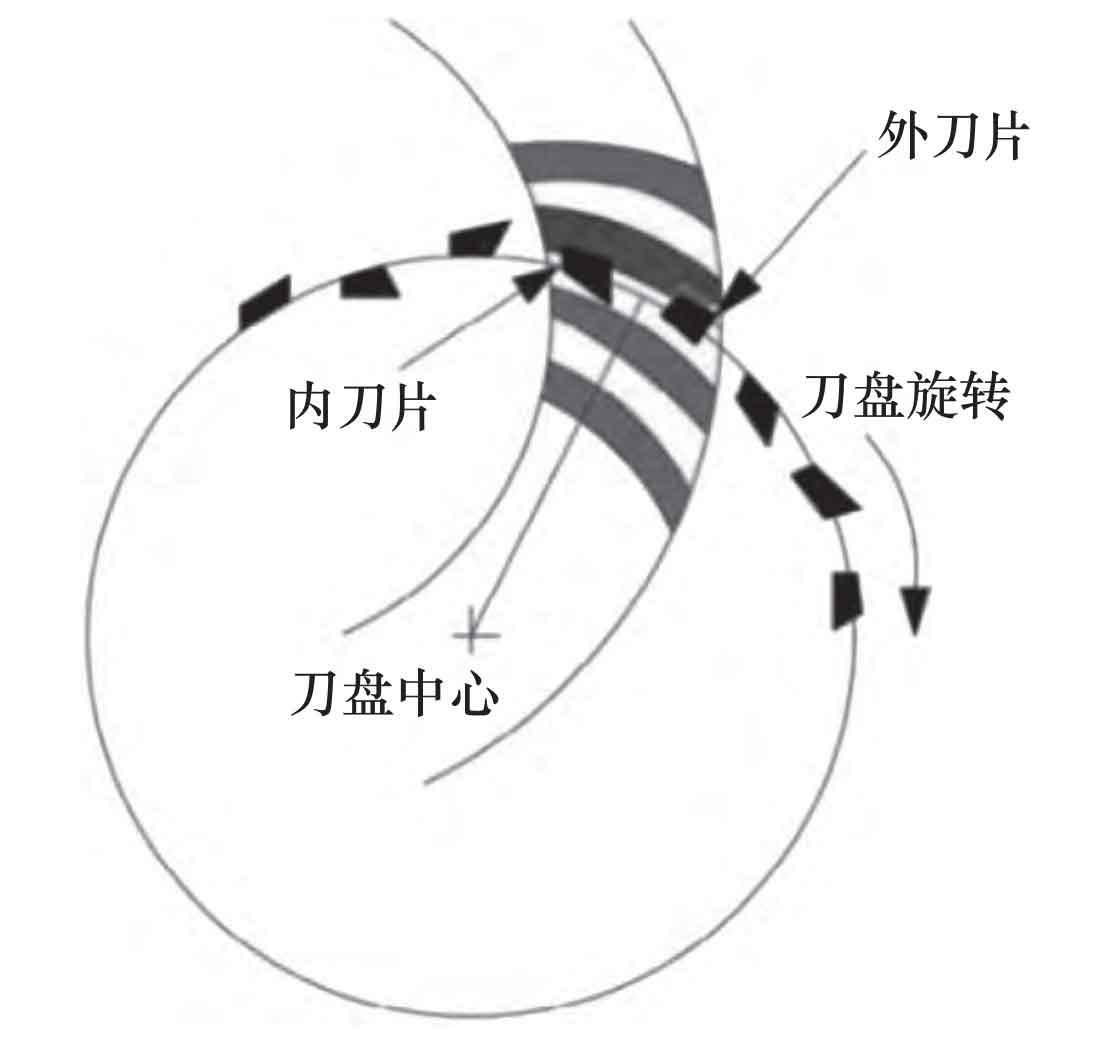

When machining spiral bevel gears with the forming method, it is necessary to adjust the mounting angle of the gear blank and the position of the cutter to keep the correct relative position. In the process of gear milling, the relative position of the gear blank and the cutter head remains unchanged, the gear blank remains stationary, the cutter head rotates and feeds along the cutter head axis. The tooth shape of the spiral bevel gear depends on the tool shape, and its processing principle is shown in Figure. When the machining of one tooth is completed, the tool retracts, the gear blank rotates for indexing, and the next tooth is processed. The cutting process is cycled until all the teeth are processed.

(1) By deducing the instantaneous undeformed cutting area in the process of machining spiral bevel gears with the forming method, and combining with the calculation results of the stress in the shear zone of the gear blank material, the cutting force model for machining spiral bevel gears with the forming method is constructed, and a simulation calculation program is compiled using Matlab.

(2) A gear milling experiment was designed to verify the theoretical model. After verification, it was found that the relative errors of the theoretical calculation results and the experimental results of the cutting force in the X, Y and Z directions were 9.24%, 13.18% and 13.25% respectively. The error between the calculated results of the theoretical cutting force model and the experimental results is within 14%, which shows that the established cutting force model has a good accuracy, and lays a theoretical foundation for the design of bevel gear machine tools, the study of tooth milling vibration and tool wear.

By deducing the instantaneous undeformed cutting area in the process of gear milling with the forming method, and combining with the stress calculation results in the shear zone, the instantaneous cutting force model of the spiral bevel gear big wheel machined with the forming method is constructed, and the theoretical model is verified by designing experiments.