1.Calculation formula of Hertz theory

The problem of contact mechanics was first proposed and studied by Hertz. He proposed the classic Hertz contact theory, but in practical engineering applications, it can only analyze and calculate problems with simple shapes and relatively simple and regular contact surfaces. Therefore, his theory has certain limitations, mainly applied to fields such as contact analysis of spur gears, contact analysis of bearing rolling bodies, and contact analysis of rail vehicles and rails.

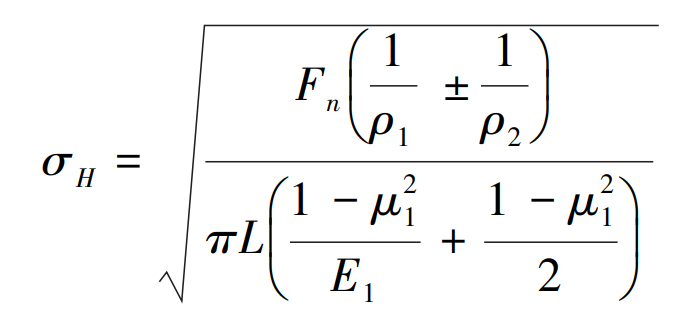

Due to the high stress on the teeth of spur gears at nodes, pitting corrosion is prone to occur. Therefore, attention is usually paid to the stress intensity at nodes. In order to simplify the calculation, a pair of cylinders with parallel axes are commonly used to replace it. The maximum contact stress between tooth surfaces can be calculated using the Hertz theory formula, and the formula and related parameters are as follows:

In the formula:

σ H: Contact stress;

Fn: Normal load, Fn=2T/dcos α;

T: Torque;

L: Is the length of the contact wire, L=3b/(4- εα);

b: Tooth width;

εα : Coincidence degree;

ρ 1 、 ρ 2: The curvature radius of the two tooth profiles at the node;

ρ : Comprehensive curvature radius, and ρ =ρ 1 ρ 2/( ρ 2+ ρ 1);

μ 1 、 μ 2: Poisson’s ratio;

E1 and E2: elastic modulus of two spur gears.

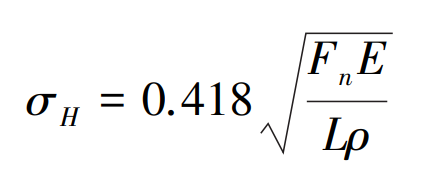

When E1=E2=E, μ 1= μ When 2=0.3, the maximum stress formula can be simplified as:

2. Calculation of parameters and contact stress of highly modified spur gear pairs

After checking the table, εα= 1.68. Substitute E1=E2=2E+11Pa and the parameters in Table 1 into the formula, and calculate the contact stress as follows: σ H=283.367Mpa, contact wire length L=32.2858mm.