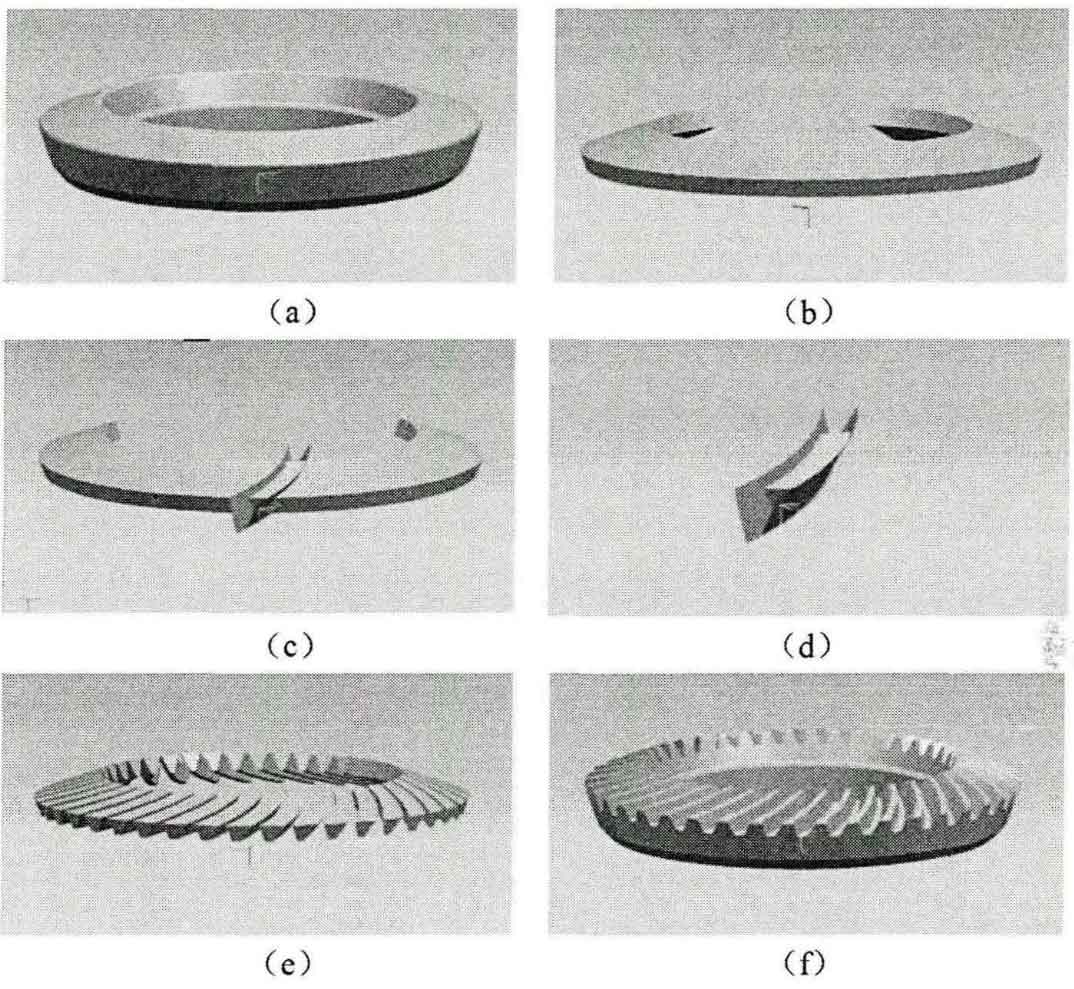

The main design parameters and tooth surface model of cycloid hypoid gear pair (Figure 1) are known, and the three-dimensional model of gear pair is constructed (taking the small wheel as an example):

(1) Establish wheel blank

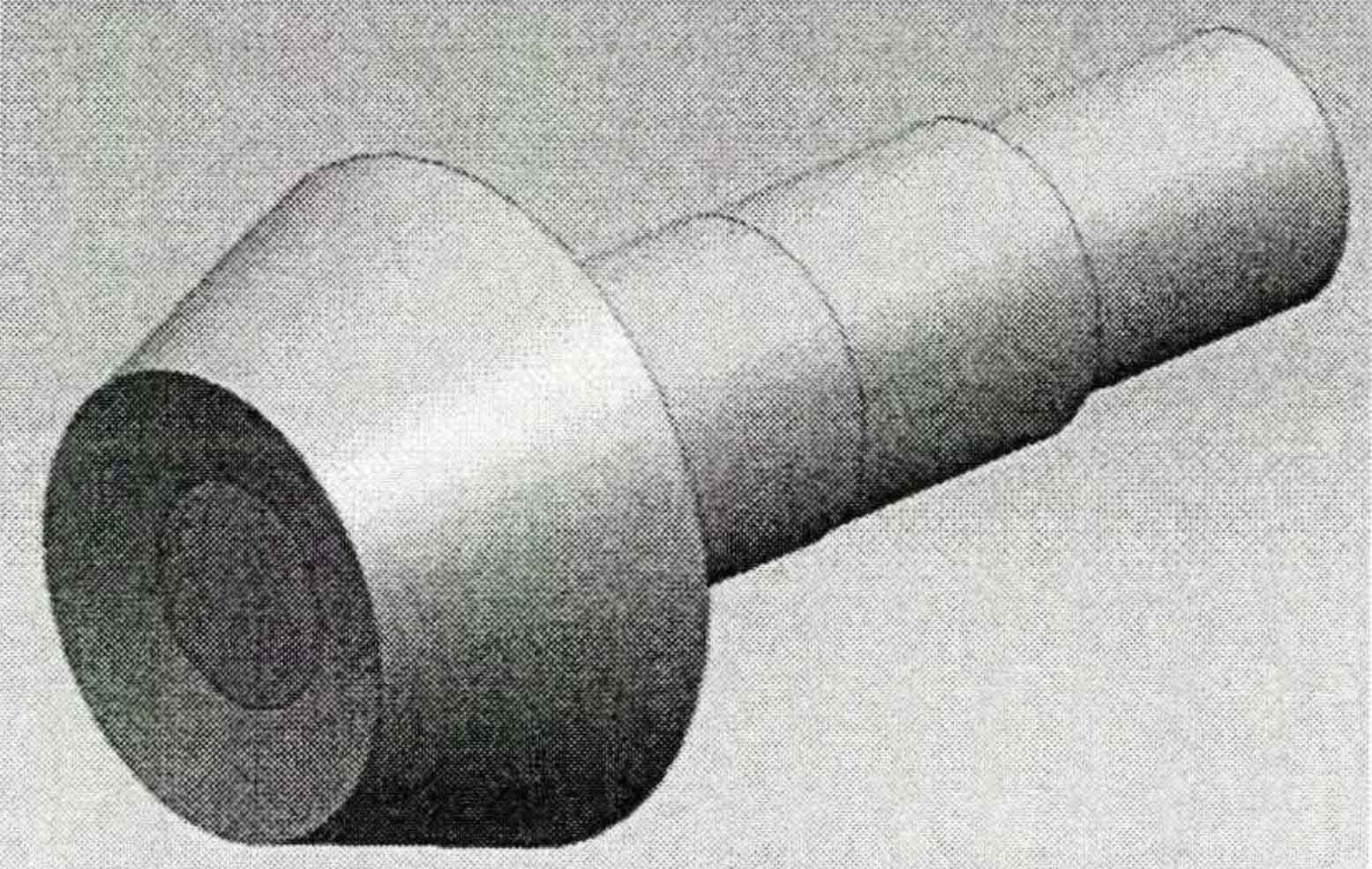

The z-axis of UG default coordinate system is taken as the axis of the small wheel, and the origin of the coordinate system is taken as the perpendicular foot of the common vertical line of the matching two axes on the gear axis. The position of the reference point obtained from the axial distance AM1 and radial distance RM1 of the reference point is used as the reference point for the sketch drawing, the profile line of the gear shaft is drawn, and the rotation command is executed to rotate the profile line around the shaft to obtain the gear wheel return solid model, as shown in Figure 2.

(2) Generate cogging entities

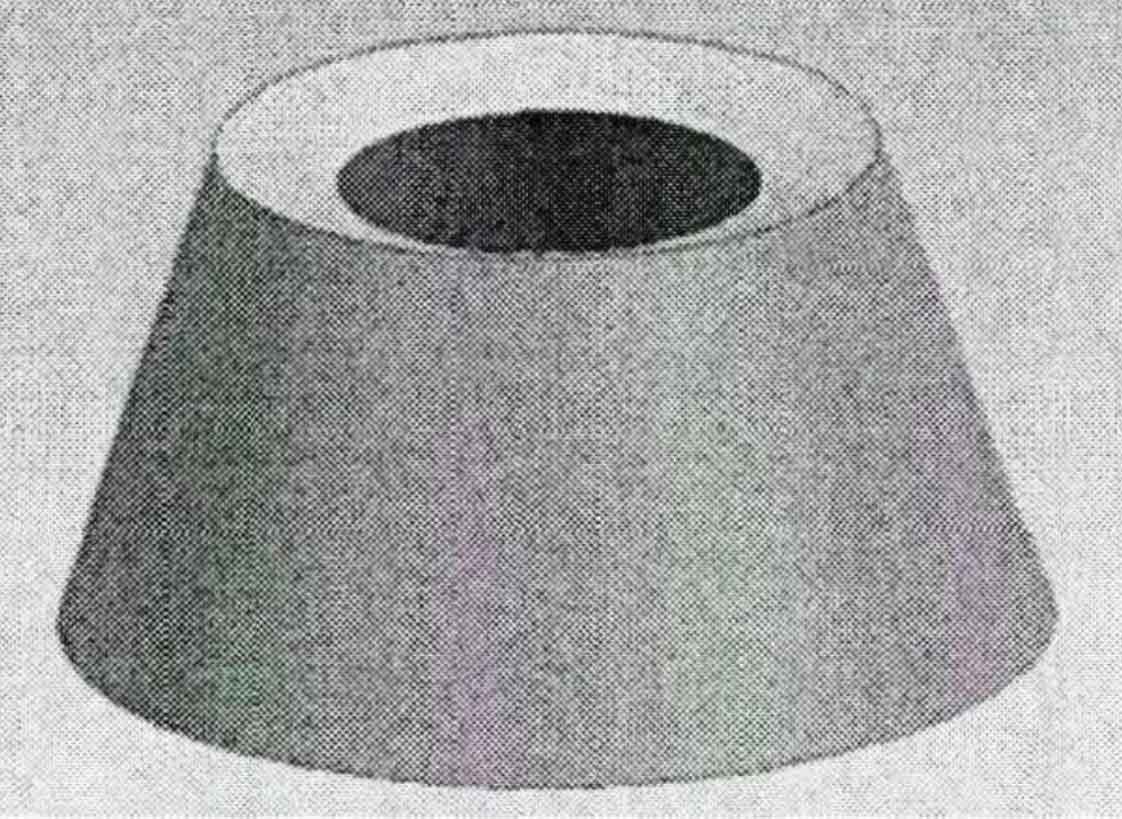

According to the dimensions of the root cone, top cone, front cone and back cone of the gear tooth, draw the contour line on the section of the gear cogging shaft, execute the rotation command, and rotate the contour line around the shaft to obtain the gear cogging ring entity, as shown in Figure 3.

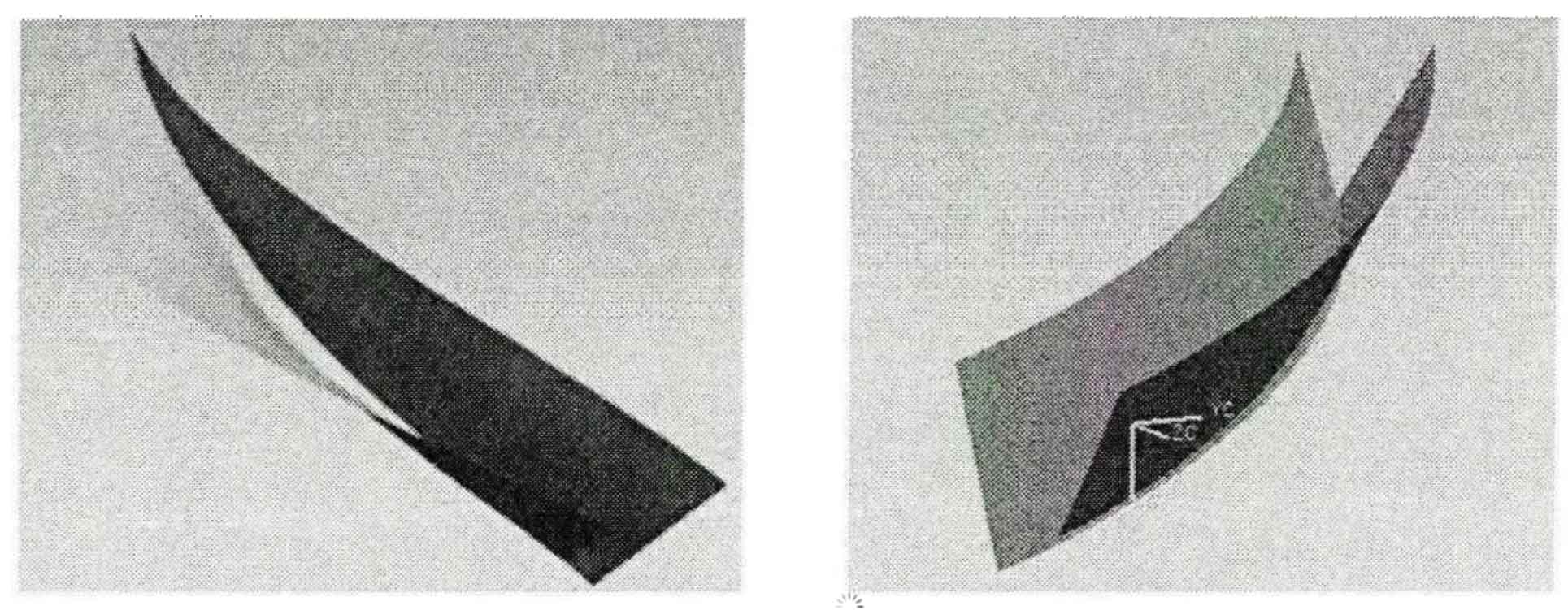

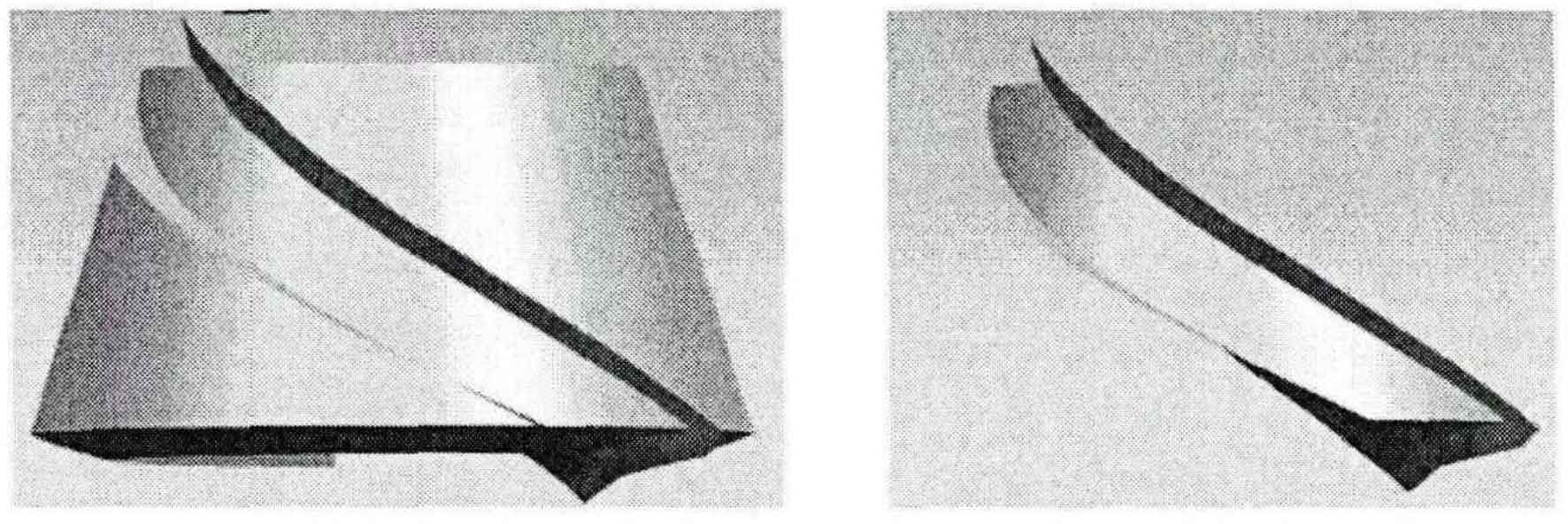

Get the two sides of the gear tooth groove based on fitting, and then execute the trim body command to trim the tooth ring entity to get a single tooth groove entity, as shown in Figure 4.

(3) Generate complete tooth profile

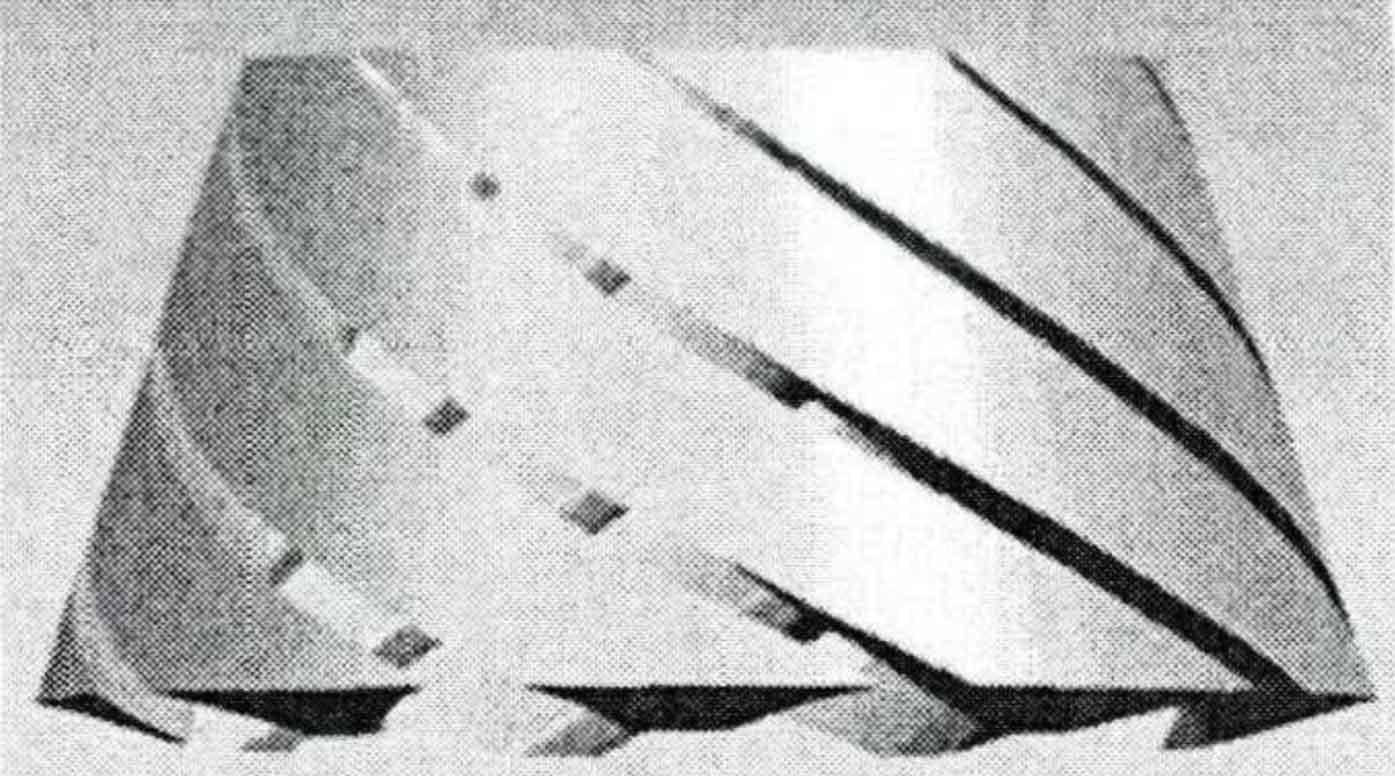

Select the generated gear cogging entities, execute the instance feature command, and make a circular array of the cogging features to obtain all gear cogging entities, as shown in Figure 5.

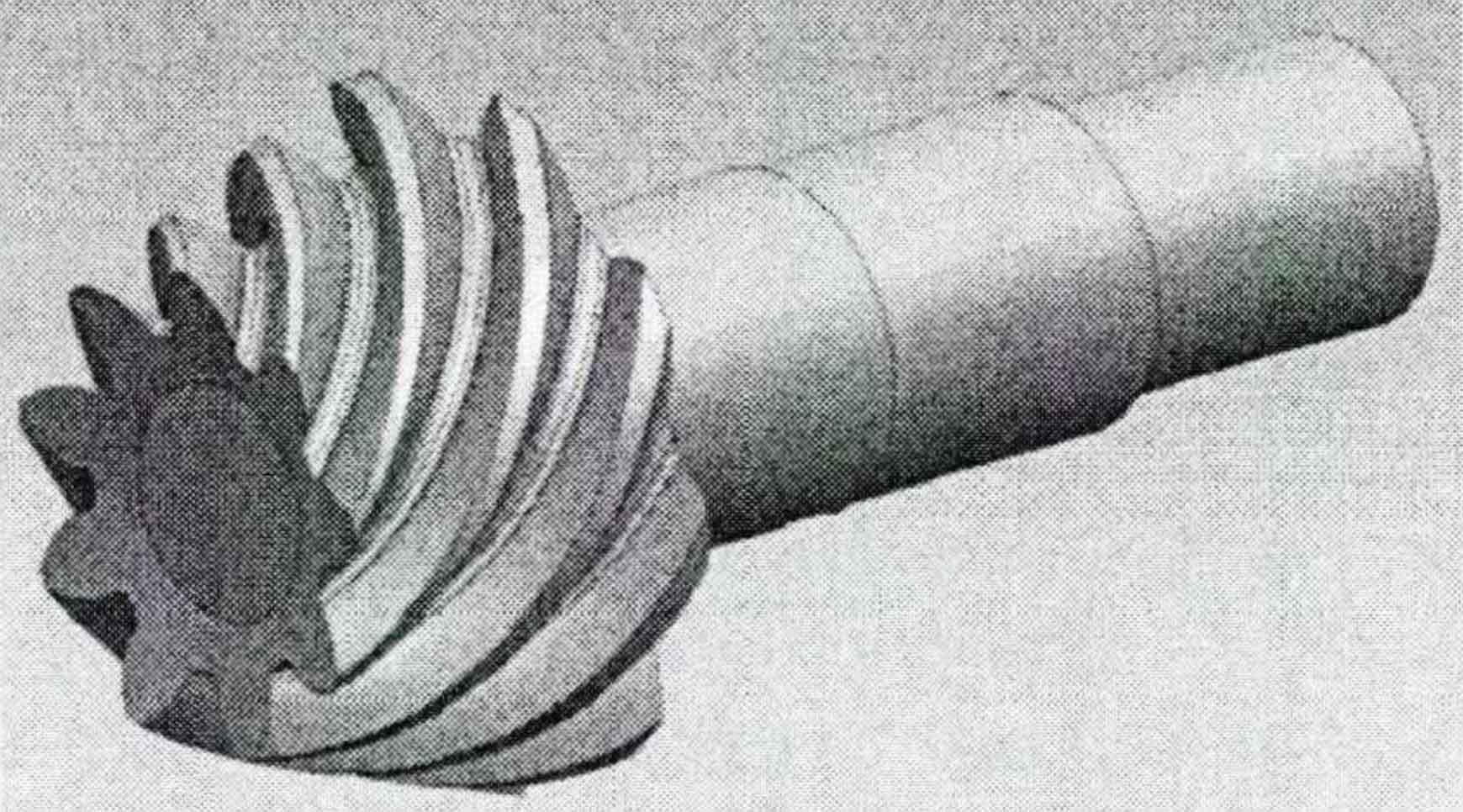

Take the obtained gear cogging entity as the tool, execute the Boolean difference command, and trim the target entity – the gear wheel to obtain the three-dimensional solid model of the gear as shown in Figure 6.

The construction process of the big wheel is the same as that of the small wheel. The wheel and the cogging ring entity are obtained by rotating, the two sides of the cogging of the big wheel are fitted by grip, the cogging entity of the big wheel is obtained by trimming the body, and the circular array of the features of the cogging instance is carried out. Finally, the three-dimensional solid model of the big wheel is obtained by Boolean subtraction, as shown in Figure 7.